Processors Report Lower Orders and Production

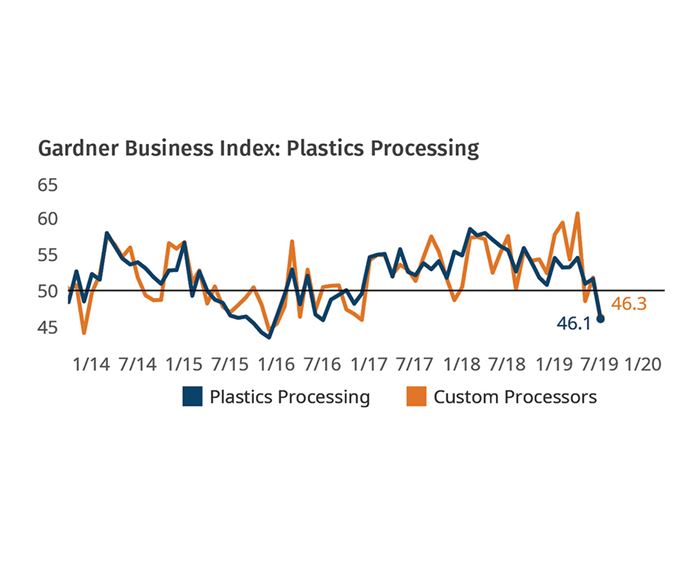

July Plastics Processing Index dips to 46.1.

Plastics processing activity changed course sharply in July, as the Gardner Business Index (GBI) registered 46.1. (Index readings above 50 indicate expanding activity while values below 50 indicate contracting activity. The further away a reading is from 50 the greater the change in activity.)

An analysis of the underlying components of the Plastics Processing Index revealed that employment, new orders and production contracted at rates not seen in nearly three years. Other than supplier deliveries—considered a lagging indicator—all components contracted.

In general, new orders and production are more sensitive indicators of economic activity change, while supplier deliveries and employment are often lagging components of the Index. During the 2015-2016 slowdown, new orders and production began contracting five months prior to supplier deliveries. Surprisingly, employment in July contracted nearly simultaneously with the initial contraction in total new orders.

Plastics Technology’s Custom Processors Index also contracted, registering 46.3 in July. Here, too, five of the six Index components contracted during the month. Custom processors indicated a steeper contraction in production, compared with the overall plastics processing industry. This more aggressive production contraction likely explains the weaker supplier deliveries among custom processors but slightly higher backlogs.

Gardner Business’ Plastics Processing Index is based on responses to surveys of subscribers to Plastics Technology Magazine.

About the Author: Michael Guckes is chief economist and director of analytics for Gardner Intelligence, a division of Gardner Business Media, Cincinnati. He has performed economic analysis, modeling, and forecasting work for more than 20 years among a wide range of industries. He received his BA in political science and economics from Kenyon College and his MBA from Ohio State University. Contact: (513) 527-8800; mguckes@gardnerweb.com. Learn more about the plastics processing Index at gardnerintelligence.com.

Related Content

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

-

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

-

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

.jpg;width=70;height=70;mode=crop)