Thermoformer’s Name Change Reflects Refocused Strategy

New identity highlights processor’s focus on technology, product quality, and food safety.

When Winkler Plastic decided to rebrand itself Nuconic Packaging in March, the move represented more than a simple name change for the PET sheet extruder and thermoformer. For CEO Alan Franz, it reflects the processor’s recent investment in new technology, increasing its capabilities in tooling and design, as well as its razor-sharp focus on customer service, and achievement of a critical food-safety certification.

Operating out of a 30,000 ft² plant (plus offsite warehouse space) in Vernon, Calif., Nuconic focuses on PET and the food market alone. It extrudes a majority of the sheet that it forms into cake domes, bowls, and other containers. The new name is an amalgamation of several words core to the processor’s mission: new, containers, and plastic. Some 30 people work at Nuconic, a 50% increase from just a few years ago.

“Becoming Nuconic Packaging is a way for us to further demonstrate the transformation that our company has made over the past year or so,” he says. “With significant investments in thermoforming technology, tooling and design capabilities, and food-safety manufacturing practices, we are now able to provide our customers with so much more than ever before.

Over the past several years, consolidation in the packaging market has created a large number of food-processing companies struggling to deal with this new landscape of suppliers. We are extremely well positioned to fill the void, particularly with regard to customer service, responsiveness, and quality.”

Last year, Nuconic bought a new Low Flex 5.0 thermoformer from Thermoforming Systems LLC, Yakima, Wash., along with new tooling and a high-speed, high-precision, linear-rail trim press designed to maximize tool life and cutting quality. Franz says the new machine improved Nuconic’s product quality, nearly doubled its capacity, and increased the range of its product offerings. The results are tangible: “Products now have dramatically reduced plug lines, improved clarity and strength, and smooth denesting for easier customer use,” he elaborates. The new equipment also “treads lightly” on the environment by producing products from recycled plastics while consuming minimal energy.

This year, Nuconic earned an “A” rating on its food-safety audit from BRC Global Standards. The BRC Packaging and Packaging Materials Standard is a leading global brand and the first standard in the world to be recognized by the Global Food Safety Initiative (GFSI) benchmarking committee.

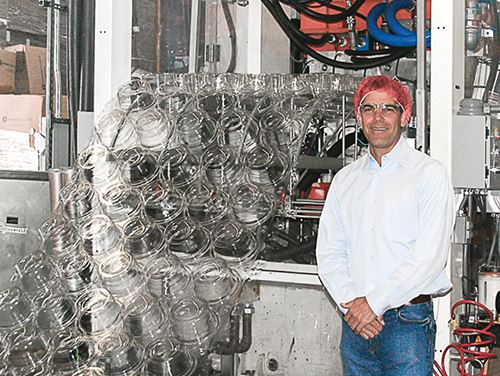

Nuconic brought on board Francisco Diaz as director of operations and engineering. Diaz, who had worked at Pactiv, is an expert in thermoforming with a solid background in tool machining, product design, and engineering management, says Franz. The company also hired Lupe Meneses as customer-service manager in 2013. Meneses brought with her 11 years of customer-service experience in food packaging.

Says Franz, “All of these initiatives add up to giving our customers confidence that our products are the best, the safest, and most considerate of the environment. Our rebranding shows that we are rapidly embracing the new to ensure a dynamic future for our company and our customers.

Related Content

-

Die-Service Cart Upgraded to Handle Screws, Chill Rolls

Processing Technologies International LLC has released its next-generation flat die servicing system, the uCAMS (Universal Cleaning Assembly and Maintenance System) Plus.

-

How to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

-

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.