Why Drying Polyolefins Might Be Right for Your Process

From a technical standpoint, drying non-hygroscopic materials such as polyethylene and polypropylene may not be necessary. However, doing so may be advantageous to your process. Here are details.

Polymers of all kinds can be classified into one of two groups: hygroscopic or non-hygroscopic. Hygroscopic materials such as nylon, ABS, PC, and polyesters—to name just a few—will attract and absorb water molecules into the plastic’s interior structure.

Non-hygroscopic plastics such as polyolefins (polyethylene and polypropylene), on the other hand, will not absorb water molecules into the polymer structure. Because hygroscopic polymers attract and absorb water molecules from the atmosphere, they must be dried prior to processing to achieve consistent production results regardless of changes in the ambient temperature and humidity conditions that occur throughout the year.

But what about polyolefins? Polyolefin processors molding and extruding products for automotive, medical, and certain other markets sometimes predry materials to remove surface moisture and, in effect, “preheat” or soften the material to facilitate melting. But this is not a common practice. Still, the fact is that processing polyolefins without predrying can lead to problems:

- Although polyolefins are non-hygroscopic and will not attract moisture from the surrounding air, they will certainly pick up some surface moisture when exposed to high ambient humidity. While a very small amount of surface moisture may not cause any visible issues in most general-purpose molding and extrusion applications, increasing surface moisture levels will cause surface finish problems such as roughness, splay, or silver streaks.

- Moving containers of polyolefins from an unheated warehouse into a warm and more humid production area may cause moisture to condense onto the cold pellets when the containers are opened.

- Polyolefins that contain colorant such as carbon black, or are filled or reinforced, will attract and hold some surface moisture.

- A good, high-quality surface finish is a necessity when plating polyolefin products, and even a very small amount of surface moisture present on the incoming pellets will result in a poor finish.

DRYING BENEFITS AND TIPS

Processors that have made the commitment to dry polyolefins have seen several benefits. Maintaining a consistent temperature and moisture level in the incoming material throughout the year helps them achieve consistent performance of the extruder or injection molding machine.

What’s more, reducing surface moisture on the incoming material results in an improved surface finish. Plus, preheating the material will reduce the energy load required from the injection molding or extrusion machine to melt the polymer.

So much for the why.

What about the how?

A hot-air dryer is recommended for drying polyolefins at temperatures in the range of 150 F to 180 F; a drying hopper should be sized for 2 hr of drying time. This type drying system will provide a stable incoming material temperature and lower the surface moisture of the pellets.

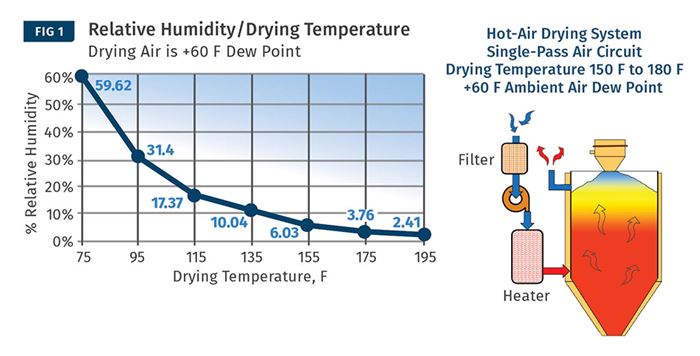

The principle of operation of a hot-air dryer is simple: Hot air will absorb and hold more water than cool air; for example, ambient air at 75 F with a dewpoint temperature of 60 F has a relative humidity of 59.62%, meaning it has absorbed over half of the water that it can absorb at that temperature. If that air is then heated to a temperature above 75 F, as shown in Fig.1, the relative humidity of the air will decrease, and the drying air then will be able to absorb more water.

A hot-air dryer will dry polyolefins down to 0.1% moisture, and often much lower, which will satisfy the vast majority of polyolefin processors. However, if your application requires an extraordinary low final moisture level, a dehumidifying dryer may be required.

Preheating the material will reduce the energy load required from the injection molding or extrusion machine to melt the polymer.

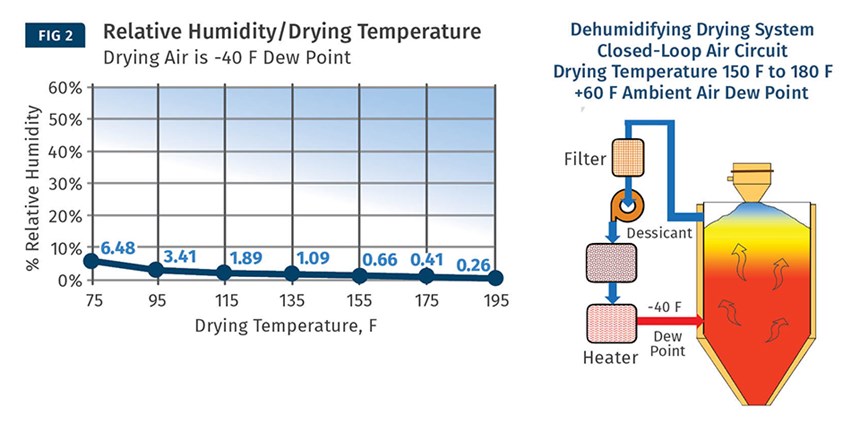

A dehumidifying dryer is a hot-air dryer on steroids. It first passes the drying air through a bed of molecular-sieve desiccant, which removes water from the drying air and lowers the air’s dewpoint. The dehumidified air is then heated, which lowers the air’s relative humidity. We now have drying air that has a very low dewpoint and an extremely low relative humidity (Fig. 2). A dehumidifying dryer can easily reduce the surface moisture of polyolefin pellets to 0.005% or lower.

Note: Relative humidity is not a term used to describe the performance of dehumidifying dryers. It is used in this article to provide a reference when comparing the performance of a dehumidifying dryer to that of a hot-air dryer.

Questions about drying? Visit the Drying Zone.

ABOUT THE AUTHOR: Pete Stoughton has more than 40 years’ experience with dehumidifying dryers and PET crystalizing systems. He has held various technical positions with the Conair Group, including technical services manager, product manager, and business unit manager. He now has his own consulting firm, Polymer Drying Services. Contact: (814) 516-3838; pstoughton@comcast.net; pstoughton.com.

Related Content

PiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreNew Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

Read MoreHigh-Output Dryer Requires Less Energy

Maguire’s ULTRA 2200 is designed to meet high throughput requirements with a max capacity of 2200 lb/hr.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More