Dow Invests in Recycler Mr. Green Africa

At full scale, the investment is expected to create approximately 200 more direct jobs, impact the lives of 5,000 waste pickers and engage more than 250,000 consumers in separation at source programs.

Dow has invested in Mr. Green Africa, the first recycling company in Africa to be a Certified B Corporation. This investment marks the first of its kind from Dow on the continent and expects to enable approximately 90 kilotons (kt) of plastic waste to be recovered over four years and recycled into new packaging applications.

With the support from Dow and other investors, Mr. Green Africa plans to expand its operations in Kenya where it is headquartered as well as in other countries in Africa, further extending the capabilities of its recycling efforts across the continent.

In addition, Dow and Mr. Green Africa also aim to co-develop more traceable, fair, high-quality post-consumer recyclate (PCR) that can be used in the production of new flexible plastic packaging – helping brand owners and other plastic manufacturers achieve their goals towards sustainable packaging solutions in Africa.

At full scale, the investment is expected to create approximately 200 more direct jobs, impact the lives of 5,000 waste pickers and engage more than 250,000 consumers in separation at source programs.

Mr. Green Africa converts locally collected plastic waste into PCR, which is then sold as a substitute for imported virgin plastics to help to close the loop on plastic waste. Alongside Dow, Mr. Green Africa works closely with brand owners and third-party plastics manufacturers to access ethically sourced, locally produced PCR, and support companies in meeting their sustainability targets.

“Our partnership with Mr. Green Africa is testament to our commitment to play our part in solving the plastics waste issue in Africa, where waste collection and sorting is a real challenge,” said Marco ten Bruggencate, Dow’s commercial vice president for packaging and specialty plastics for EMEA. “We are delighted to announce this milestone in our continued collaboration with Mr. Green Africa, which will enable us to have an even greater impact on diverting plastic waste from landfill and giving this valuable material a second life.”

Dow’s partnership with Mr. Green Africa officially launched in November 2019 in Kenya and was specifically established to drive the collection and recycling of flexible packaging, which was not supported by existing systems. Since then, Dow has invested into the partnership to prevent flexible plastic from ending up in landfill or the environment, support local livelihoods by incentivizing waste collection and enable the creation of a market for flexible plastic packaging.

By incentivizing waste pickers with a higher, stable income through a fair-trade plastic waste sourcing model, establishing sorting centers that allow them to bring plastic waste in for payment, and then enabling this waste to be processed in recycling centers, the partnership is expected to make material recovery significantly more effective in the region. Dow has also supported the development of an app through which local communities in Kenya can sort and separate the plastic waste in their homes more efficiently, and schedule it to be collected and processed through the plastic recycling system by Mr. Green Africa.

“If we want to make lasting and systemic change in solving one of the world’s biggest challenges – plastics waste, we need to work with like-minded and relevant value chain partners. Mr. Green Africa has been able to lay a solid foundation,” said Keiran Smith, CEO and co-founder of Mr. Green Africa. “However, with a vision aligned partner like Dow, we will be able to advance towards changing recycling in a systematic way.”

Dow will work alongside Mr. Green Africa to address critical gaps in waste management systems, enabling more plastics waste to be sorted, collected and reused in new applications. Photo Credit: Dow

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MorePurpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

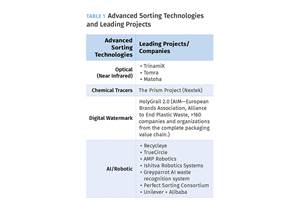

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRead Next

Dow to Start Supplying Circular Polymers to Customers in 2022

Advancements in the U.S. and Europe will enable Dow to produce circular polymers from materials previously considered unrecyclable.

Read MoreDow’s Largest PE Facilities Further Recognized for Use of Sustainable Feedstocks

Five of Dow’s largest production sites in North America and Europe have received ISCC PLUS recognition.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More