The 5 M’s of Molding—Part 5: Method

Once a molding problem has been identified, use “method” to determine whether the issue is with Man, Mold, Machine or Material.

Once a molding problem has been identified, use “method” to determine whether the issue is with Man, Mold, Machine or Material.

The final M in the 5M equation refers to “Method”. Method is a very broad category that directly applies to Man, Mold, Machine and Material. Method also considers all internal and external contributors that affect the key measurables of a lean production operation.

Key measurables in plastic injection consist of production efficiency, scrap and downtime. The primary goal of lean manufacturing is 100% efficiency, 0% scrap and down time that is planned, not unplanned. These goals can sometimes seem to be challenging to achieve, but with proper analysis and approach the end result can be successful and profitable.

As measurables are recorded, a part history is developed. It is this historical data that we use to identify repeating and/or poorly performing variables. It also helps us to scrutinize what areas of production need improvement.

Once clear identification of a problem has been accomplished, it is then time to ask the question, “is this problem directly associated with Man, Mold, Machine or Material?” In some situations, only one of these will require change. In others, it could be all four that need correction. By establishing which of these categories need to be addressed, it becomes easier to develop solutions that will improve our “method”.

Here is an example of the 5 M method in use:

A Japanese headlight manufacturer determined through scrap data that a significant amount of scratches was appearing on parts already assembled. The cost of this sort of rework is quite costly… parts already assembled would need to be tore down, replacement lenses molded and then a second assembly performed to refurbish the part to an acceptable quality level.

Man, Mold, Machine and Material were all considered to determine when and how the scratches were occurring. After review of the entire production process from in-mold to assembly, the cause of the scratches was tracked to two separate problems, both of which were directly related to “man”. The problems were:

Parts produced were packed into cardboard for storage. Some scratches were due to operator handling as they were packed. The boxes were stacked on skids and then transported into warehouse racking.

When parts were needed, they were pulled from warehouse and then transported to the assembly area. Some scratches resulted directly from parts jostling as they were handled by warehouse personnel.

To eliminate the problem, special carts were developed made of a soft cloth that allowed for the parts to be packed, stored and transported to assembly without the threat of scratched product from packing and transport. What had been a very large problem became non-existent through proper analysis and methodical approach.

The 5M approach to molding is an excellent way to clearly identify problems, which is the foundation to any problem solving event. Full understanding of any problem helps to develop the most credible solution to the problems presented. Develop, maintain and regularly review recordable data for measuring production, scrap and downtime efficiencies. As the level of historical data increases, factors that improve production are discovered and implemented. That same data also offers insight into what problems exist. Clearly define the problem, and then review whether it is directly related to man, mold, machine or material. Remember that it could be one, several or all four contributing to the situation.

Develop a solid list of all areas contributing to the problem, and then systematically define solutions to those issues. Effective solutions require a complete understanding of the problems being addressed. Utilize all personnel directly related to the problem to best develop understanding and methods for correction. Effectively defining problems and solutions is dependent upon the complete knowledge base of your entire team. As their ability to create and adapt to change is refined, continuous improvement becomes more enjoyable. Clearly defined solutions add to the strength of your organization, bringing it one step closer to world-class manufacturing.

Garrett MacKenzie is the owner and editor of www.plastic411.com. Mackenzie started in plastics at the age of 19 as an operator, eventually moving up through the ranks to engineering and management over a 29-year timeframe. He currently works as a plastic injection consultant in engineering and training capacities. He can be contacted at garrett.mackenzie@mail.com.

Related Content

Minnesota Rubber and Plastics Opens Innovation Center

The plastics and rubber compounder and molder has opened the 9000-ft2 center that’s intended to help speed product development with design, prototyping, testing and production capabilities.

Read MoreLSR Molder Invests in Canadian Operation

Starlim is investing $10.4 million in its London, Ontario, LSR injection molding site, with plans to add 26 jobs.

Read MoreFinding a Niche in LSR Tooling

20 years ago, southern California moldmaker M.R. Mold & Engineering pivoted to LSR tooling, giving it a foothold in a challenging but growing market.

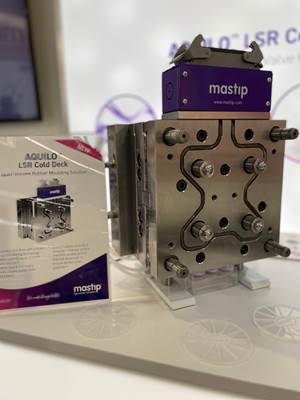

Read MoreNew LSR Cold Deck

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More

(2).jpg;maxWidth=300;quality=90)