Victrex at K 2019: Innovating with PEEK

Expansion of Victrex’s PEEK portfolio ranges from 3D printing and films to composites, gear solutions and a food-grade family.

Using the theme “The Element of Invention” at the upcoming K 2019 show, Victrex will spotlight the latest additions to its portfolio of PEEK and PAEK polymers. Included are additive manufacturing (AM/3D printing filaments and powders), composites, films, gear solutions, and a new food-grade family, all of which complement the innovations that followed the invention of PEEK over 40 years ago, which have ranged across key industrial sectors in advanced applications, often replacing metals.

“The invention of PEEK polymer has clearly had a very positive impact across industries and, in fact, across the globe. We could never have imagined the continuous stream of innovation this high performing versatile polymer would make possible. Visitors to the Victrex K 2019 show booth can look forward to pioneering new grades as well as exciting progress on forms and parts in critical applications where high performance polymers deliver a strong advantage in the development of new markets,” said Victrex CEO Jakob Sigurdsson.

Here are some more details on the latest Victrex portfolio additions:

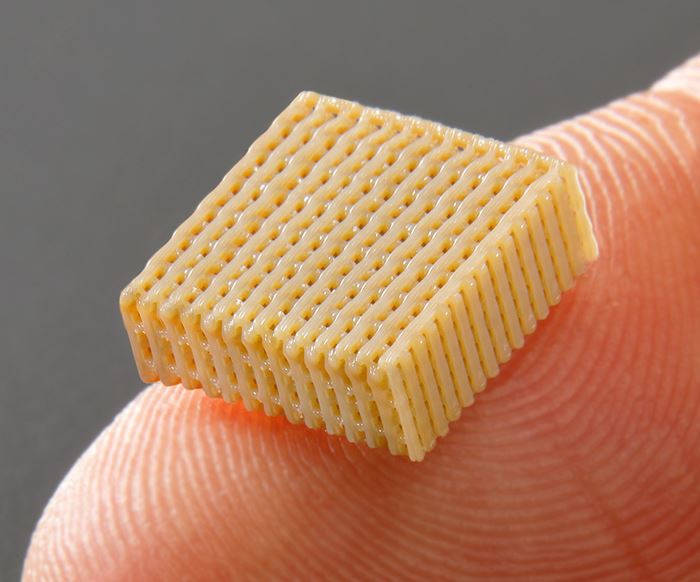

▪ AM/3D Printing—There is a new PAEK filament for filament fusion (FF) systems and a fine PAEK powder for selective sintering (SS) units. They are said to deliver better results with improved mechanical properties in printed parts and easier printing than past attempts to use PEEK in additive manufacturing. Victrex is investing in these new materials optimized for AM and pairing them with new machine technology in order to create integrated solutions, while working directly both with key industry partners and customers.

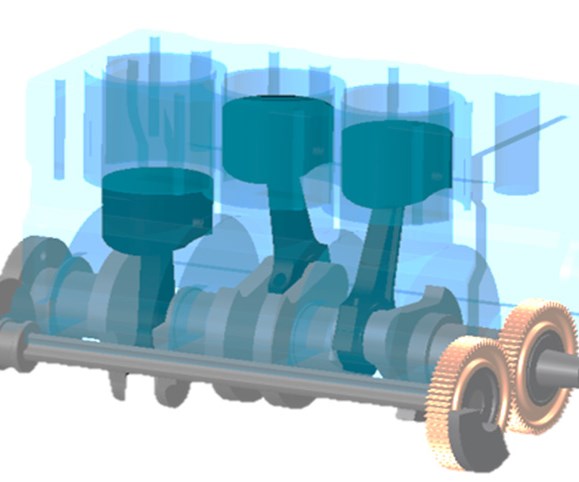

▪ Automotive: Driving innovation in powertrain—Cost-effective polymers, forms and parts for the automotive industry include the tribologically optimized Victrex PEEK polymer, thin Aptiv films and robust Victrex HPG high precision gears. Together, says Victrex, they contibute greater CO2 efficiency and improved durability, as well as a potential reduction in total system cost in conventional, hybrid, and electrical powertrains.

With its gears solutions, Victrex is enabling Tier 1/OEM customers to work with one partner, from concept to commercialization, who supports the development and testing of high-precision Victrex HPG gears, as well as the manufacturing of these gears as a component for integration into larger systems (e.g. within the engine, transmission, pump, actuator, and chassis).

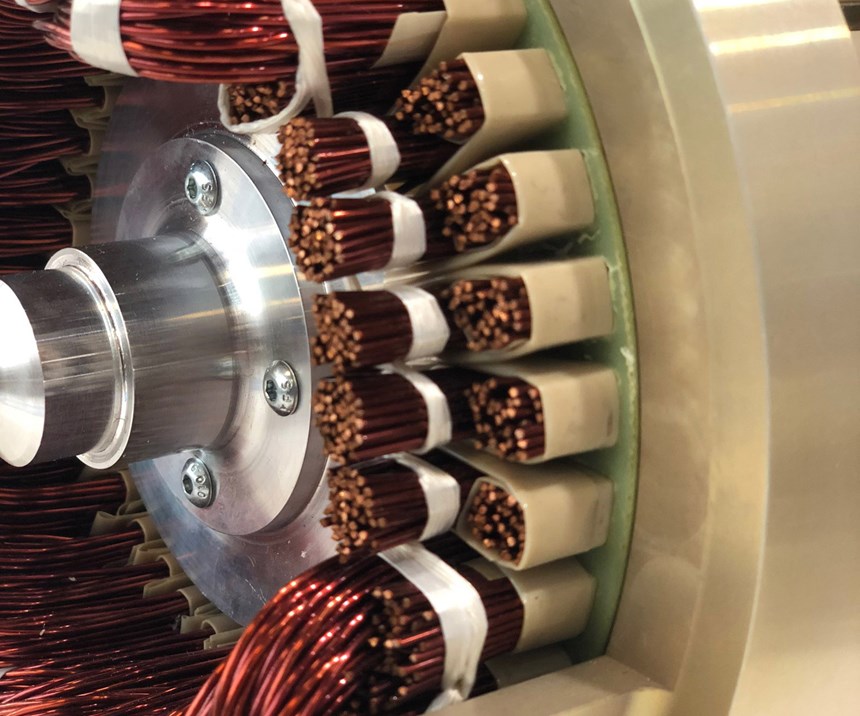

In electric drives, PEEK film-based electrical insulation can help improve thermal management, reliable operation and reduce overall system cost. With the automotive industry transitioning to electric vehicles, the quest for more efficient high-density e-motors and lower cost is still on. Most e-motor manufacturers have opted to use the Permanent Magnet Synchronous Machine (PMSM) in which the design of the insulating system is instrumental. Computer simulation from highly regarded third party specialists on an established 80 kW EV e-motor have shown a potential 5% increase torque output in a same size e-motor, enabled by 40% thinner Aptiv slot liner, enabling a 2% increased copper content (slot-fill factor). Additional simulation has indicated that the excellent thermal conductivity of Aptiv film results in improved thermal management and a reduction of peak winding temperatures by 2-3°C (36-37°F) versus traditional laminates.

▪ Electronics: Aptiv films for advanced performance in next-generation electronic devices.—As 'high tech' continues to advance, the trend is to electronic devices that offer improved performance and reliability in new and lighter form factors, while packed with a range of features. Aptiv films reportedly deliver all the benefits of high-performance PEEK polymer in a thin format and so provide the versatility and high performance required to address customers' complex demands for a variety of devices in this fast-moving market. The benefits of Aptiv film include: proven mechanical strength; resistance to wear, high temperatures and harsh chemicals; and electrical stability and low moisture absorption. These outstanding attributes mean that Aptiv film can be applied in a wide range of products, such as micro speakers, 5G RF antenna substrates, and battery insulation, and also in chip and display manufacturing.

▪ Aerospace: The next dimension of PAEK thermoplastic composites—The aircraft industry has forecast that more than 35,000 new aircraft will be required within the next 20 years. Meeting this kind of escalating demand clearly calls for new approaches and new technologies in aerospace engineering.

Victrex AE 250 composites have been shown to have mechanical, physical and chemical resistance properties typical of members of the polyaryletherketone (PAEK) polymer family such as PEEK, but with a 40°C (104°F) lower crystalline melting temperature, at only 305°C (581°F).

The unique material delivers a combination of cost reduction, light weight, design freedom, strength and production speed in next-generation components. This includes: up to 6.5x faster for in-situ processing for laser welded AFP processing, up to 40% cost savings vs. metals, and up to 70% lighter than metals with equivalent strength and stiffness.

A breakthrough in the time- and cost-efficient production of complex aircraft parts was recognized with a JEC Innovation Award 2019 earlier this year, for an all-thermoplastic drive-shaft system overmolded with an integral gear that is set to advance the use of thermoplastic composites in aerospace. The OrganoTube and gears of the drive-shaft system are using Victrex AE 250 PAEK unidirectional tape (UDT) and PEEK polymers in combination with innovative processing technologies. This innovation is expected to open up enormous potential for reduced cycle times and large-scale industrial production.

▪ Manufacturing & Engineering: Reducing part production costs, while increasing reliability and maintenance intervals.—The reduction of maintenance costs and downtime are just two of many needs across a range of manufacturing and engineering industries. Using VICTREX PEEK solutions can contribute to keeping highly automated industrial environments moving, with minimal maintenance and at the highest safety standard. The metal replacement polymer can enable durable solutions that improve the lifetime of components—for example up to 40% for conveyor belts or two times the operating lifetime for rotor shaft bushings.

In the food and beverage industry, developing the next generation manufacturing equipment is a particularly complex challenge. Companies are facing numerous requirements for health, safety and hygiene established by regulatory authorities, the industry and consumers. To help OEMs meet these demands, Victrex has introduced a dedicated food grade portfolio. Compared to metals, the Victrex FG family of high-performing PEEK thermoplastics offers additional benefits in terms of productivity and performance for OEMs.

In addition, with the adoption of Industry 4.0 technology, PEEK can offer manufacturers the opportunity to optimize efficiency and also reduce production costs, when compared to the use of metals, as these may require costly multi-step machining to manufacture. Applications on display at K 2019 will include Victrex PEEK injection molded bushing, bearings, and scroll compressors as well as dryer conveyer belts using PEEK-based Zyex fibers.

▪ Energy: Survive and thrive in the extremes.—In 2018, Victrex introduced Victrex CT 200 for applications at cryogenic temperatures [-150°C to -200°C (-238°F to -328°F)]. As the latest member of the Victrex CT PEEK polymers, the 200 grade series reportedly exhibits improved sealing over a wider range of temperatures, compared to commonly used materials such as PCTFE. It does so at low temperatures on account of its greater ductility, and at high temperatures due to its superior creep resistance.

Victrex CT polymers have also been shown to maintain better dimensional stability, with a lower coefficient of thermal expansion than incumbent materials. The higher thermal conductivity of the PEEK material enables a fast response to temperature changes, ensuring the material is engaged with the counter-surface at all times. In addition, laboratory testing indicates that they may require less torque to actuate since they have a lower static and dynamic coefficient of friction compared to PCTFE. This results in less wear, higher performance and a potential for cost savings.

Given decades of experience in delivering innovative PEEK thermoplastic solutions for the energy industry in both onshore and offshore oil and gas markets, Victrex understands the need for component reliability and efficiency in harsh environments. These requirements are especially relevant in wind energy which is currently faced with the critical challenge of reducing its Levelized Cost of Energy (LCOE). Reducing the LCOE requires the wind industry to design larger turbines to generate greater power output, improve reliability to reduce repair and maintenance costs and deploy turbines in remote and harsh offshore environments. These increasingly demanding turbine requirements are pushing the limits of metals and traditional polymer solutions.

Related Content

New Designs for Electric & Hybrid Packaging and Industrial Blow Molding Machines

Introduced at K 2022, Bekum’s 21 models in the new EBLOW 8 Series and XBLOW designs include all-electric packaging machines from small to large, plus industrial units with a novel two-stage clamp in servohydraulic or hybrid versions.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreAll-rPET Bottles with Glued-in Handles Save Material

At K 2022, KHS is showing a 2.3 L PET bottle with glued-in handle that offers 10% material savings and other advantages over clip-in handles. Bottle and handle are both 100% rPET.

Read MoreMold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More