Chroma Color Adds Analytical Capabilities to its Arsenal of Infrared-Reflecting Colorant Technology for Outdoor Applications

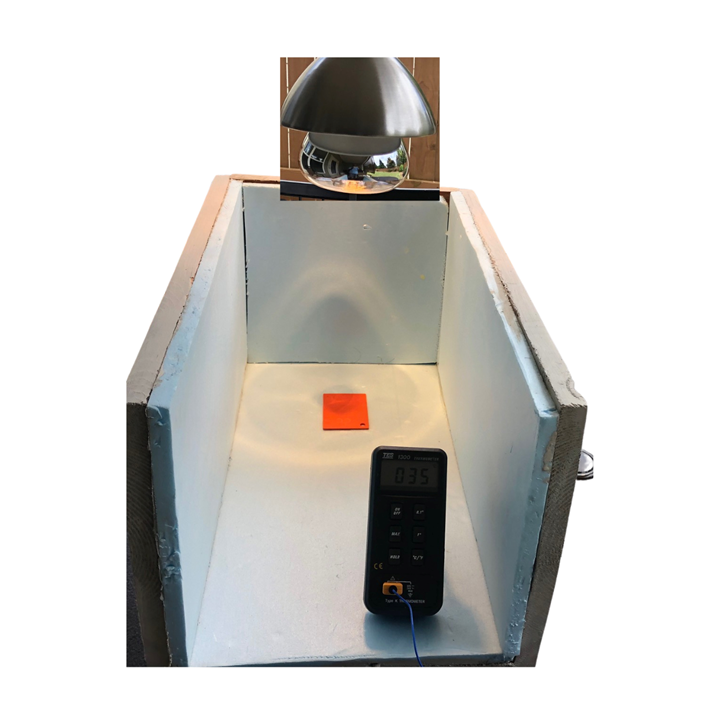

Chroma’s ASTM testing apparatus for measuring temperature rise ensures color concentrates meet criteria for reducing heat build-up in dark plastics.

Chroma Color is now offering manufacturers of exterior products customized color formulations that reduce Total Solar Reflectance (TSR)—a technology that minimizes the heat build-up on the surface of dark colored plastic products. TSR is expressed as a percentage between 0 and 100%. These rates indicate a products ability to reflect solar energy. With years of experience in providing processors with infrared-reflecting color concentrates for exterior durable goods that must withstand elements for an extended period, the company is now even better equipped with in-house analytical capabilities.

To ensure a processor’s color concentrates meet the criteria for reducing heat build-up on dark plastics, Chroma’s technical team uses the ASTM D-4803-97 method to measure the temperature increase. This testing provides useful comparative data on heat build-up of various polymers and color formulations. Carbon black plastic color typically has the highest rating of heat buildup. Therefore, this ASTM test method compares the heat buildup of a customer’s chosen color against a carbon black plastic control sample.

Related Content

-

3 Types of 3D Printed Tooling for Injection Molding

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

-

K 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

-

Masterbatches Reduce Gloss in PLA and PETG 3D Printed Products

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.

(2).jpg;maxWidth=300;quality=90)