Digital Watermarking Consortium Advances Technology for Sorting & Recycling Plastics

Europe’s Digital Watermarks Initiative HolyGrail 2.0 gains new members and advances to Phase II pilot projects.

A consortium of more than 85 European companies across the consumer packaging value chain is proceeding to the next step in its Digital Watermarks Initiative HolyGrail 2.0. This is a pilot project to prove the viability of digital watermarking technologies for accurate sorting and thus higher-quality recycling of packaging materials. Digital watermarks are essentially barcodes, the size of a postage stamp, that are unnoticeable to the naked eye. These are printed repeatedly to cover the surface of a package. They encode a wide range of attributes, including the materials of construction. Once the used package enters a waste-sorting facility, the digital watermark can be detected by a standard high-resolution camera on the sorting line. Based on the attributes “read” by the camera, the package could then be more accurately sorted than by current technologies, such as NIR spectroscopy, which cannot reliably identify multi-material structures.

Digital watermarks the size of a postage stamp, but not perceptible to the naked eye, are repeated all over the product surface, without affecting printed branding and other information.

As reported in a March Close-Up, the first phase of the project concluded in May 2019 with a proof-of-concept sorting trial at Tomra Recycling of Norway. In June of this year, a new project facilitator was named for Phase II of the project, Brussels-based AIM, the European Brands Association (aim.be). The plan is to launch an industrial pilot to validate the technology at an industrial-scale test sorting facility, with brand owners and retailers working together with packaging and technology suppliers to modify their packaging with digital watermarks. One participant, is Mondi, the Austrian-based global producer of paper and plastic flexible packaging. A founding member of the HolyGrail Pioneer Project, it now lans to conduct full-scale industrial trials with key customers in the near future. Another original member of the project, Dutch IML specialist Verstraete IML, was elected in September to be one of the 11-member HolyGrail 2.0 Leadership Team.

Also in September, German extrusion specialist Reifenhäuser joined the Digital Watermarks project as part of the R-Cycle initiative (r-cycle.org). R-Cycle is the open, global tracing standard for the entire life cycle of plastic packaging. The overall goal is to ensure recyclability by seamless documentation of all recycling-relevant packaging properties in a cloud database accessed via a digital watermark. Underway for two and half years, the R-Cycle project was presented at K 2019 and has developed the capability to map all recycling-related data digitally during film extrusion, converting and package filling and provide all this information to third parties via the internet. Together with various partners, Reifenhäuser has set up a functioning data platform that is connected to production lines. Reifenhäuser and other R-Cycle members have several pilot projects underway with major resin suppliers, brand owners, retailers and independent institutes. The projects focus on development of recyclable and recyclate-containing recipes, marking technologies, and deployment of the standardized data system. Along with Reifenhäuser, R-Cycle presently includes Arburg, Brückner Maschinenbau, Kautex and the Institute for Plastics Processing (IKV) at RWTH Aachen University in Germany.

Related Content

Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

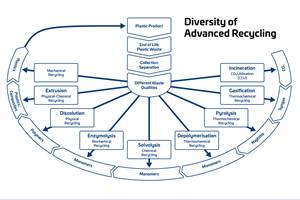

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreRead Next

New Product ID Technologies For Industry, Retail & Recycling

Confirming material composition and manufacturing source, anti-counterfeiting, waste sorting, and retail check-out scanning may all get a boost from new ID technologies.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

(1).jpg;maxWidth=970;quality=90)