Life Cycle Analysis Shows Pyrolysis Can Reduce Carbon Footprint of Cracking Operations

Research from Argonne National Laboratory describes greenhouse gas benefits of partially substituting pyrolysis oil for fossil fuels in the production of HDPE and LDPE.

A study published in The Journal of Cleaner Production, and supported by funding from the American Chemistry Council, describes greenhouse gas (GHG) benefits of substituting pyrolysis oil from post-use plastic for naphtha and fossil fuel gases in steam cracking operations.

The study considers two types of facilities, pioneer facilities with a capacity of less than 50,000 tons/year and “Nth” facilities, with capacity greater than 50,000 tons/year. The scaling factor is significant, the use of pyrolysis oil in pioneer facilities increases GHG emissions, while GHG emissions from Nth facilities are lower than that of conventional operations.

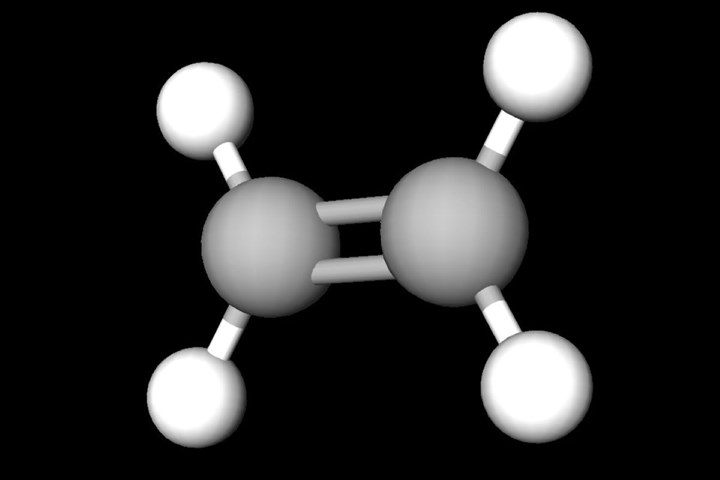

Cracking operations produce monomers for plastic production. In the United States, crackers are fed with an average of 6% naphtha and 94% gases. Substitution of naphtha with pyrolysis oil provides the greatest benefit in terms of GHG emissions. Photo Credit: National Library of Medicine

The study also considers two substitution ratios, 5% and 20%. When substituting only 5% pyrolysis oil for naphtha and gases, the elimination of chlorides and other contaminants by hydrotreatment is not necessary. Hydrotreatment contributes significantly to the GHG emissions of using pyrolysis oil. At a substitution ratio of 20%, hydrotreatment is necessary to protect equipment, bringing down the GHG benefit on a per kilogram basis.

From the recycler’s perspective, the substitution of pyrolysis oil provides a 23% reduction for HDPE production and an 18% reduction for LDPE production. However, these numbers set aside the 95% of production still being carried out by traditional means in this scenario. The producer still needs to source the other 95% (from fossil fuels) in order to make the 5% recycled material, so from the cracker’s perspective the benefit is around 1%.

Expanding the system boundaries to include end-of-life disposal increases the GHG benefit further, especially when compared against incineration.

The authors identified the availability of operational data on steam cracking and hydrotreatment processes as a limitation of the study. Detailed information is considered proprietary, and values were based on available literature and discussions with industry partners.

Related Content

-

Fundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

-

Polyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

-

The Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

.png;maxWidth=300;quality=90)