Polyplastics' PBT and PPS Targeted to Autonomous Driving Applications

Polyplastics sees its Duranex PBT and Durafide PPS as particularly suited to sensors used in radar and camera bracket systems.

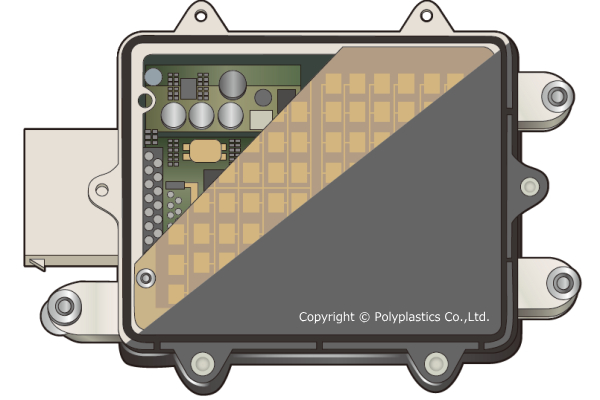

Japan’s Polyplastics Co., Ltd., (U.S. office in Farmington Hills, Mich., is among the material suppliers who are positioning their innovative resin products for use in Advanced Driver-Assistance Systems (ADAS) parts that enable autonomous driving. More specifically, the company’s Duranex PBT and Durafide PPS materials - targeted for sensors in radar and camera bracket systems – show great promise in delivering low warpage, dimensional stability, and low dielectric constant.

In radar housings, manufacturers seek materials with low dielectric constant, stable radio wave transmissibility, and low water absorption. The market has been employing SPS (syndiotactic polystyrene) and PEI for dielectric properties, and PPS for low water absorption and chemical resistance. To meet cost challenges, manufacturers have started to incorporate PBT into their designs.

Polyplastics reports that water absorption has little effect on Durafide PPS 1140A6, but some impact on Duranex PBT 330HR. As a result, the company is working on the development of new PBT grades with enhanced low-dielectric properties and low water absorption.

For the radar bracket itself, electromagnetic wave shielding properties are needed to protect against unnecessary reflected waves. Polyplastics’ electrically conductive grades, Duracon POM CH-10 and EB-10, and Duranex PBT 7300E, are all being actively considered while new PBT grades with stronger electromagnetic wave shielding properties are under development.

For car-mounted, sensing camera brackets, low-warpage and high-rigidity materials like Duranex PBT 733LD and 7407 are generally preferred. The company has also developed matte technology which uses a laser treatment to reduce noise (scattered light). The laser treatment results in favorable gloss and blackness levels. Polyplastics will continue to explore long-term durability and different process conditions to reduce treatment time.

Related Content

-

ABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

-

Injection Molded Tape and Resin “Sandwich” Technology Debuts

During its Mobility Days in Austria, Engel and KTM Technologies debuted an all-plastic molded motorcycle seat base produced via a tape-sandwich process that can run in a standard molding process.

-

Molder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.