Injection Molding: Low-Cost Structural-Foam Press for Pallets

Wilmington Machinery’s latest is built to compete with Asian machines in this size range.

Wilmington Machinery has introduced what it believes to be the lowest-cost U.S.-made structural-foam machine for molding pallets. It’s positioned to compete on price with Asian-built machines of comparable capacity. The new Lumina Pallateer Model PM-1C has 350-ton clamp and ability to mold pallets up to 48 × 52 in. in size and weighing up to 40 lb. The two-stage (extruder/accumulator) injection unit has an extruder capacity of 1200 lb/hr of HDPE, sufficient to producer 30 pallets/hr.

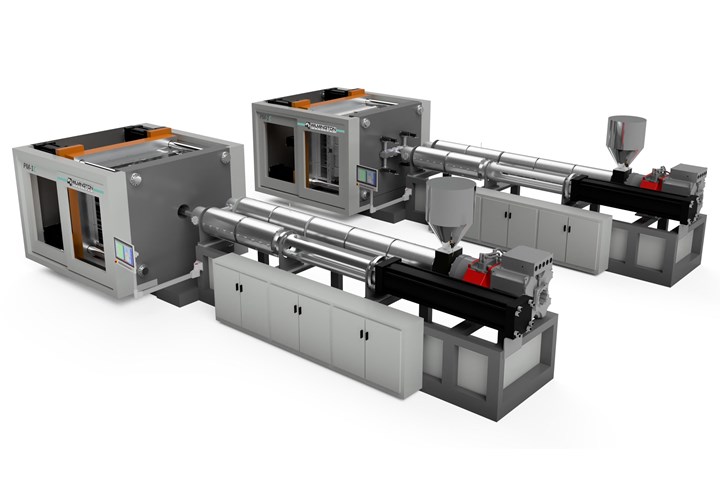

Wilmington Machinery Lumina Pallateer Model PM-1C in single-nozzle (l.) and classic multi-nozzle structural-foam versions.

The machine boasts small footprint and low energy consumption. Its hybrid design incorporates servo-electric extruders and hydraulic injection and clamping. The 30:1 L/D extruder has an injection port for nitrogen gas and can process up to 100% recycled flake. Two versions are available—single-nozzle and “classic” multi-nozzle structural-foam manifold (both are shown here). Hot-runner molds, robots, and other accessories are available from Wilmington, along with training.

Related Content

-

Slimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

-

Medical Grade Injection Molding Machine Line is Cleanroom Ready

JSW America says the J100ADS-110U medical grade molding machine has been optimized to prevent dust, rust and other contaminants.

-

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.