Slimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

A thinner version of Engel’s all-electric, e-mac injection molding machine will debut at NPE2024, providing molders with width reduction of up to 16%. At the show, an e-mac 1565/310 will mold a bottle tray from a single-cavity mold supplied by Haidlmair. Engel says despite the thinner profile, the slim e-mac offers the same mold space as standard versions and the ability to accommodate large molds like the bottle tray. Equipped with a recycling package consisting of a highly abrasion- and corrosion-resistant screw as well as a melt filter, the e-mac will mold the trays at the show from regrind.

A hybrid Engel e-speed 610/90 designed for high-speed packaging applications will run a 4+4 family stack mold producing tamper-evident food containers and lids. Applying in-mold labeling (IML) and two significantly different part sizes, the machine’s hybrid design enables high injection pressures and speeds with very short injection strokes.

At NPE2024 the new e-mac 1565/310 will mold a bottle tray from regrind using a Haidlmair mold.

Source: Engel

Nexteco, which was acquired by Top Grade Molds in 2018, creates what it calls stack mold harmonic arm-centering devices. Mold or machine mounted, the synchronized centering device can be optimized for family molds with asymmetrical opening, minimizing machine clamp stroke and cycle time. At the Engel booth, a Nexteco asynchronous mold-carrier system, complemented by an integrated water manifold, enables simultaneous molding of both containers and lids. In addition to the tool, Top Grade Molds also supplied its Modular Mold Change system for swift product changeovers. Automation is provided by Campetella, with vision inspection by Mevisco, labels by MCC Verstraete, Frigel process cooling and resin from Washington Penn.

In a demonstration of quick mold changes, an 80-ton tiebarless hydraulic victory 330/85 will apply a Stäubli QMC quick-clamping system. The two molds to be swapped in and out are from Roembke Mfg. & Design and will mold salad tongs and a fruit bowl, respectively, from Shell HDPE. Using RFID for mold identification, the machine automatically adopts the correct process parameters for the new mold upon switching without operator intervention. The iQ weight control automatically adjusts the process parameters to account for material property fluctuations and changes in ambient conditions, shot by shot. An Engel viper 12-linear robot removes the parts with end-of-arm tooling which is also identified using RFID and exchanged via quick coupling.

Engel and Staubli will demonstrate quick mold changes using a Roembke tool on a Engel victory 330/85. Source: Engel

Two-component diagnostics cartridges will be molded in cleanroom conditions on an all-electric e-motion 440H/160TWP combi M running a cube mold on a horizontal rotary table.

Engel says this fully integrated production cell showcases the potential for maximum production from minimal space, thanks in part to the dual-face mold, with 32 cavities each, from Hack Formenbau. The indexing table in the combi M design divides the machine’s mold-closing area in the center to enable production from both tool faces in parallel. In this setup, the secondary injection unit is situated on the moving platen.

Two robots also work in parallel to remove and pack the cartridges. An Engel viper 20-linear robot takes the two-component parts from the machine and deposits them in trays, while an Engel e-pic pick-and-place robot stacks the fully populated trays with an intermediate layer into boxes and then discharges them via an integrated tray server.

In LSR, Engel will showcase micromolding of valves weighing just 0.001 g. Partnering with ACH Solution, a tiebarless all-electric Engel e-motion 50/30 TL with a microinjection unit molds the LSR valves from a 32-cavity tool. A viper 12-linear robot working with an optical testing unit by ACH Solution, ensures precise handling and inspection of the microcomponents. The iQ weight control validates consistent shot weights despite any viscosity differences in the two-component LSR material from Wacker.

Engel will partner with ACH Solution to mold 0.001g microvalves from LSR on a 32-cavity tool.

Source: Engel

A servo-hydraulic, two-platen duo 770 WP tech U.S. machine will showcase the production and decoration of automotive components. The large-area sliding table mold from Schöfer will mold a front panel in a single cycle using Engel foilmelt and clearmelt technologies. Translucent polypropylene from SABIC is joined with polyurethane (PUR) from Ruehl for cost and weight savings, by applying a Kurz inmold decoration (IMD) film. PUR dosing equipment comes from Italy’s Cannon. The process combines decoration and scratch-resistant surface creation through IMD and PUR coating, resulting in a part with electromagnetic transparency. The fully integrated production cell utilizes easix automation.

Six years since its NPE2018 debut, the Wintec line will be presented via an 830-ton t-win 750/7800. The machine will mold garage floor tiles from 100% recycled ocean waste, using an integrated Engel viper 40-linear robot for part removal. Here again, the iQ weight control simplifies the use of recycled materials. Wintec customer CH3 Solutions supplies the mold for this cell, with raw material from Chilean firm Atando Cabos, which takes on ocean waste by recycling discarded fishing ropes in Patagonia. ExxonMobil supplies material and additives for enhanced processing.

In addition to Engel’s booth, the company will have machines running at partner exhibits as well. At the Canadian Association of Moldmakers (CAMM), an e-motion 44/180 WP will mold flip-top closures from a Cap-Thin Molds tool. LSR supplier Wacker will feature a flexseal 300 with rotofeeder molding a lemon press from silicone. Ilsemann Automation will be molding a petri dish on an e-motion 2440/420 T – US, and Vasantha Tool Crafts PVT Ltd. will use an e-mac 50/90 US to mold 1-mL syringe.

Related Content

Semperit Acquires Rico Group

The global maker of specialized polymer products for industrial applications, including hoses and belts, has purchased the Austrian headquartered liquid silicone rubber molder and moldmaker.

Read MoreBeacon MedTech Solutions Names New President

The Massachusetts-based medical molder and contract manufacturer has appointed industry veteran Jim Colony.

Read MoreLSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

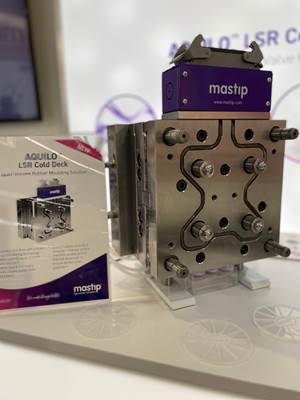

Read MoreNew LSR Cold Deck

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)