Long-Stroke Shuttle Blow Molders for Challenging Applications

Wilmington Machinery is offering to build special, customized machines for difficult applications up to 1.5 gal.

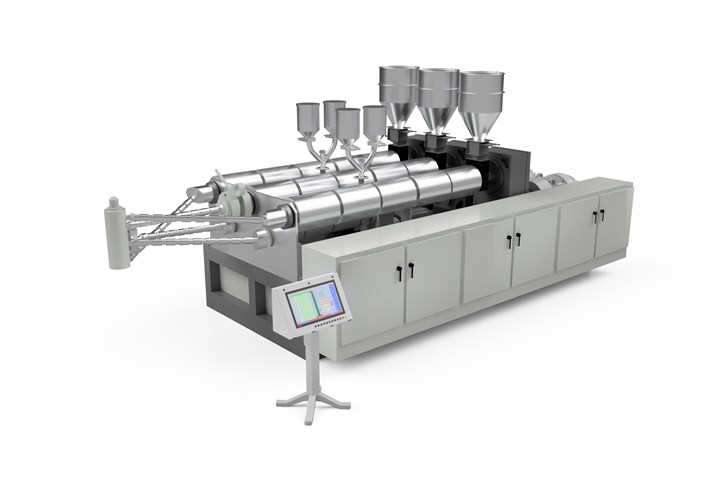

In response to customer requests, Wilmington Machinery is offering to build customized long-stroke shuttle blow molding machinery for applications not well suited by other such machines on the market. According to sales manager Jim Boos, such applications could include larger containers with heavier walls and unusual geometries. Anticipated applications would range from 6 oz 1.5 gal.

Coextrusion of up to six layers is available on the long-stroke machines and is also newly available as stand-alone coex packages.

These machines, like all Wilmington blow molders, are now supplied with new and more sophisticated control systems that offer remote troubleshooting, SPC charting, trend analysis, graphing and integrated auxiliary control on a large flat-panel display.

Also available on the long-stroke machines is coextrusion capability in up to six layers for single or dual parisons and all container sizes. Coextrusion is now for the first time available from Wilmington not only as part of machine systems, but also as stand-alone packages.

Related Content

-

How Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

(2).jpg;maxWidth=300;quality=90)