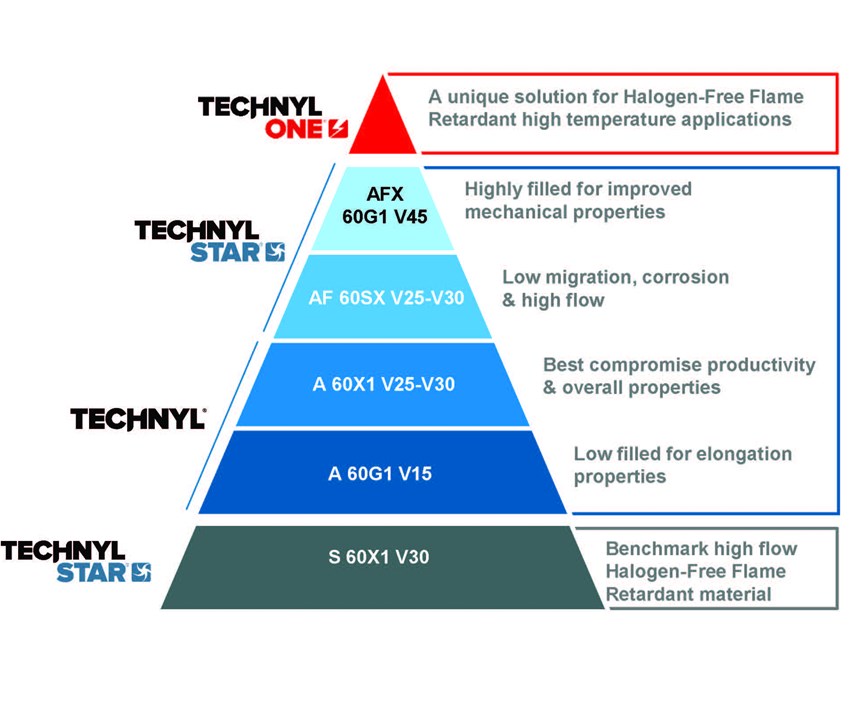

Materials: Enhanced Halogen-Free Flame-Retardant Nylon 66 Family

Solvay’s new generation Technyl One is designed for smart meters and circuit breakers for digital cities.

Solvay Performance Polyamides, Lyons, France (U.S. office in Alpharetta, Ga.), has launched an enhanced version of Technyl One, the company’s range of halogen-free flame-retardant nylon 66 materials, designed to meet the challenges of the digital transforming of cities by delivering more performance, safety and environmental protection.

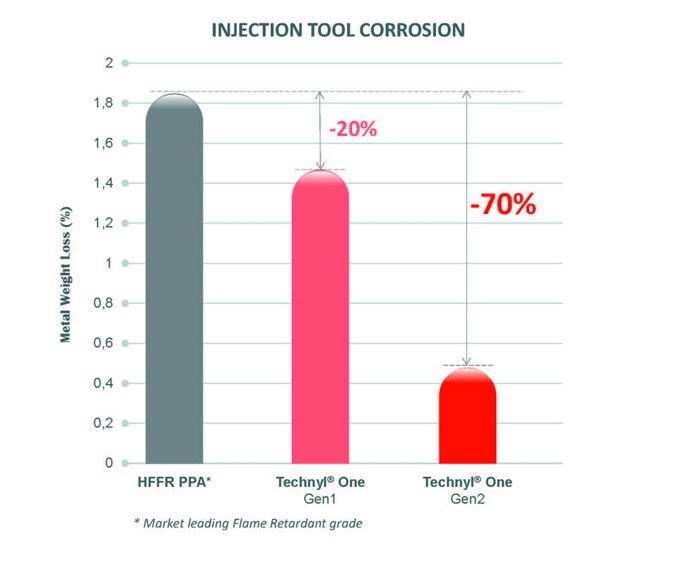

The new generation of Technyl One increases the potential for miniaturization of electrical and connection safety systems while retaining the same level of safety. Therefore, at 0.4mm (0.016 in.) wall thickness, these devices remain compliant with UL94 V0 (1), ensure optimal performance (Relative Thermal Index) at 150 C/302 F, and are fire resistant (Glow Wire Ignition Temperature) up to 800°C/1472F. This material also has good environmental performance, avoiding scrap and decreasing corrosion by more than 70 percent versus a traditional high temperature halogen-free polymer.

“Rapidly-developing ‘smart technologies’ triggers an increase in safety systems and their connectivity, along with the management of a smart grid. This requires solutions that are compliant with higher levels of performance, sustainability and cost-efficiency. To support the emergence of these new applications such as smart meters and circuit-breakers, we have strengthened our Technyl One range. It paves the way for more complex designs by providing improved processability and flame-retardant properties consistent with the latest safety standards while offering a halogen-free solution for sustainability,” said Florence Schutz, Global Market Manager for Solvay’s Performance Polyamides. “

According to Schutz, thanks to the enhanced Technyl One, major players in this industry have already been able to optimize the design of some electrical equipment, while retaining an equivalent level of safety. In some cases, OEMs changed their production process, replacing conventional materials with Technyl One”.