End Markets

All-Electric IMM Advances for Packaging, Medical and LSR

NPE2024: Sumitomo SHI Demag’s show focus is on the application of all-electric injection molding machine technology for a variety of markets and components.

Read MoreComposting Additive for PLA Added to FDA Inventory of Food Contact Substances

Carbios’ Active enzymatic solution for the biodegradation of PLA is now included in the FDA Inventory of Effective Food Contact Substances, enabling its use in flexible and rigid food packaging.

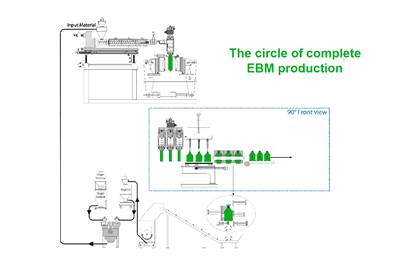

Read MoreAll-Electric Shuttle and Stretch-Blow Machines

NPE2024: Meccanoplastica shows off a double-sided shuttle for containers up to 5 L and a reheat stretch-blow molder for up to 2.5 L PET containers with four cavities — both all-electric.

Read MoreNew 15-Ton, All-Electric Shuttle

NPE2024: Plastiblow demonstrates double-station, quad-head machine making 500-ml HDPE bottles.

Read MoreLarge Recip-Screw Machine Boasts Numerous Upgrades

NPE2024: Rocheleau adds side-shift option, new controls and diagnostics to its RS-90 unit.

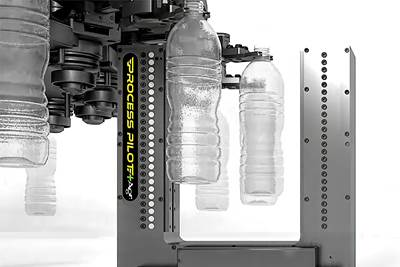

Read MoreSensor-Based PET Stretch-Blowing Controls and Bottle QC Instruments

NPE2024: Agr International is showing its newest systems for automated stretch-blow molder control and for measuring thickness distribution of bottles or sheets.

Read MoreHigh-Output Drum Machine Boasts Fast Cooling, Color Change

NPE2024: Graham Engineering’s new 40-lb accumulator press has adjustable-height extruder platform.

Read MoreFreudenberg Medical Breaks Ground on Second Costa Rica Production Facility

The $25 million investment will quadruple the manufacturing footprint for high-volume, minimally invasive catheters with injection molding and extrusion capabilities.

Read MoreShibaura Launches Medical-Specific Injection Molding Machine

The 110-ton, all-electric EC110SXIII press debuted at Plastec West molding pipette tips.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read More

(2).jpg;maxWidth=300;quality=90)