Stretch Blow Molding

Latest Stretch Blow Molding Articles

VIEW ALLStretching the Boundaries of Large PET Containers

NPE2024: Cypet shows off new capabilities for its ISBM machines.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreAll-Electric Shuttle and Stretch-Blow Machines

NPE2024: Meccanoplastica shows off a double-sided shuttle for containers up to 5 L and a reheat stretch-blow molder for up to 2.5 L PET containers with four cavities — both all-electric.

Read MoreKrones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreAdding Remote Service Functions for PET Bottle Blowing

KHS has added features to its internet machine communications portal for PET stretch-blow molding.

Read MoreSidel Launches Ultra-Small, Ultra-Light PET Bottle for Liquid Dairy Drinks

Sidel’s drinkable yogurt bottles from 65 to 150 ml save material and energy in production, and they’re qualified for 100% rPET.

Read MoreLatest Stretch Blow Molding News And Updates

North American Distributor for Italian Blow Molding Heads and Stretch-Blow Molds

Globeius now offers Preven blow molding heads and tooling in U.S., Canada and Mexico.

Read MoreFirst Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreLightweight 100% rPET Bottle Design, Tooling for CSD

Sidel addresses challenges to blowing high-quality, lightweight CSD bottles with 100% rPET.

Read More‘Ultrafast’ Machine for Large PET Bottles

Sidel’s new EvoBLOW XL stretch blow molder makes up to 10 L PET bottles at up to 18,000 bph.

Read MoreCompact, Affordable Robotic Palletizer for FHPC Bottles

Sidel introduces high palletizing performance in a compact, affordable package for food, home and personal care bottles.

Read More‘Contactless’ Accumulator Is Gentle to Superthin PET Bottles

Sidel’s Gebo AQFlex protects ultralight PET water bottles from dents at Suntory Japan.

Read MoreFeatured Posts

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreStaying Ahead of the Curve: How a Blow Molder Thrives as a ‘Technology Company’

Aptly named Ring Container Technologies beefs up R&D staff to meet customers’ future needs before the customers even know what they will be.

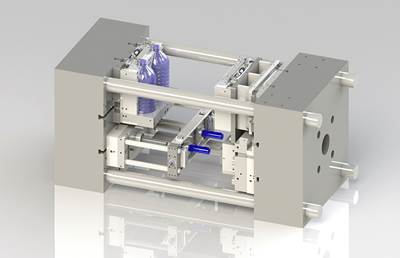

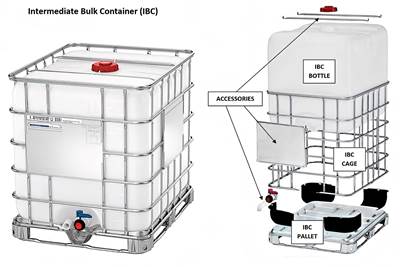

Read MoreStretch-Blow 1000-Liter IBCs from PET

Cypet introduces a one-stage ISBM system to provide a clear alternative to HDPE bulk containers.

Read More