Tooling for Plastics Production

Tooling for plastics production includes molds, mold components, ejector pins, mold bases, nozzles, mold cores, mold cavities, conformal cooling.

Narrow Your Tooling Search

ESSENTIAL READING

VIEW ALLBest of Fattori, Tooling Know How

In this collection of articles Jim Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

Read MoreHow To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

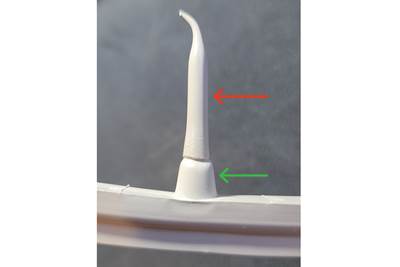

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreHow to Design Three-Plate Molds – Part 3

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

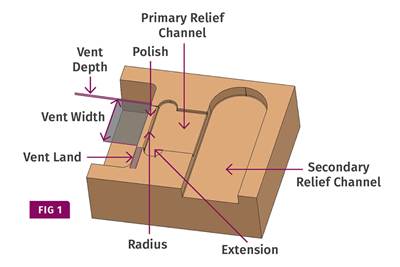

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreLatest Tooling News And Updates

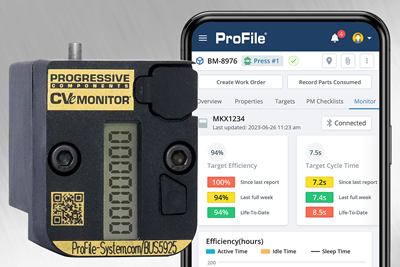

Mold Monitor Adds Wireless Connectivity

NPE2024: Progressive’s CVe OnDemand software now offers wireless connectivity.

Read MoreIn-Booth Mold-Cleaning Demonstrations

NPE2024: iD Additives is also featuring displays of chemical foaming agents, purging compounds, plastic mold cleaners, and water cleaning and maintenance systems.

Read MoreMold Tracking, Simplified Cooling Line Coupling and More

NPE2024: Hasco, which marks its 100th anniversary in 2024, highlights multiple product lines making their U.S. show debut, as well as a revamped responsive website that simplifies online ordering.

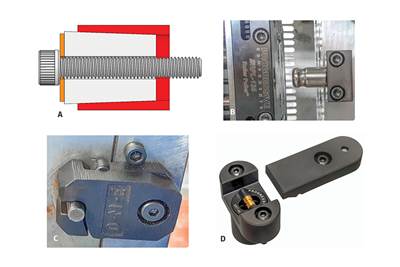

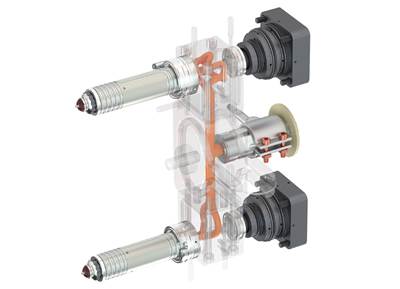

Read MoreCompact Collapsible Core Features Independent Movements

NPE2024: DME’s DURA collapsible core’s two-piece design enables each segment to open and close independently.

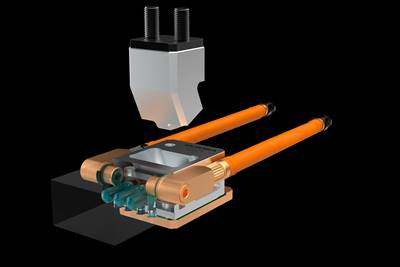

Read MorePlug-and-Play Modular Hot Runner Controller

NPE2024: Spark Industries’ patent-pending MOD24 hot runner controller offers unlimited plug-and-play of 6-zone hot runner control modules.

Read MoreCooling Added to Compact Slide

NPE2024: CUMSA adds cooling to the Compact Slides (CS) line launched last year.

Read MoreFeatured Posts

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreHow to Design Three-Plate Molds – Part 3

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

WatchWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreTooling Supplier Categories

- Thermoforming Molds

- Blow Molds

- Nonferrous Metals for Molds

- Mold/Die Management Systems

- Injection Molds

- Mold Steels

- Cutting, Stamping, Trimming Dies

- Mold/Tooling Simulation and Analysis Services

- Quick-mold-change Equipment

- Mold Making and Repair Equipment

- Mold Components

- Custom Machine Builders

- Injection Blow Molds

- Consultants - Design, Manufacturing, Purchasing

- Rotational Molds

- Part/Mold Inspection or Digitizing

- Tool Engraving, Texturing Equipment

- Mold Texturing, Tool Engraving

- Mold Evacuation Systems

- Mold Grease

- Rotational Molding Machines

- Mold/Tooling Design Services

- Compression/Transfer Molds

- Mold-cleaning and Maintenance Chemicals

- Nonmetallic Tooling Materials

- Hot Runner Components

- Used Molds

- Used Machinery

- Foam Molds

- Compression/Transfer Presses

- Prototype Molds