Considering Scaling Up for More Output? Follow These Tips

Keep these calculations handy when you are trying to decide whether a bigger extruder will get you the output you need.

Sooner or later, every processor considers scaling up their extruder sizes for more output. It’s well known to extruder designers how increasing the diameter of the barrel bore boosts potential output. But to many others it’s not as well understood. Output at open discharge (no head pressure) can be closely estimated using the old “drag flow” or output equation, which for single screws is:

Drag Flow = [0.95 × π2 × D2 × H × (L-W/L) × RPS × (sin Ѳ × cos Ѳ)] 1/2

Where:

D = Bore diameter, in.

H = Metering channel depth, in.

L = Flight lead, in.

W = Channel width, in.

RPS = Screw rpm/sec (rotations/sec)

Ѳ = Helix angle, degree

Notice that the bore diameter (D) is squared in the equation. So, if we keep all the other terms the same, using the same polymer, and increase just the bore diameter from a 3 in. to 4 in., what would the potential output difference be? The effect of head pressure must be considered first, as it subtracts from the output.

Squaring just the bore size and leaving all the other terms the same results in (4)2/(3)2 = 1.77. That means the potential output of the 4-in. extruder is at least 77% greater than that of the 3-in. extruder.

However, you also need to scale up the channel depth (H) for the larger screw diameter to maintain similar shear rates, melting rates, melt temperatures and melt quality. Designers have several methods for scaling up the channel depth to match the scale-up of the bore size. Basically, it’s matching the shear rates in the metering channels in particular. Using a channel-depth estimate for scaling up when processing identical polymers would increase the projected output by a further 1.3:1 for a total of (1.77 x 1.3) = 2.3. So going from a 3-in. to a 4-in. bore size could be expected to increase the output more than twofold.

This approach has been used many times in the past to get a good first estimate for scaling screw outputs. I have used it in designs from 3 lb/hr to 120,000 lb/hr for screws varying in diameter from half-inch to 18 in., with good results. Again, this is an estimate and not the complete answer, but it is very useful. Assuming the same L/D, there are a number of additional factors that need to be considered in the final design, such as the geometry of the feed and compression sections, the head pressure and mixing.

The smaller the scale-up/scale-down, the more accurate it is.

Once the output is estimated, it can also be used to calculate the required drive power to achieve a similar motor load for the scaled design. Power is a closely defined quantity almost always monitored on an extruder, and since an extruder is a relatively closed system the power to heat and melt the polymer with a properly scaled screw design is largely proportional to the output.

Once screw rotation begins, almost all the energy entering the polymer is from shear heating due to screw rotation and not from heat conducted from the barrel, because of the poor thermal conductivity of polymers. If that weren’t true you could simply turn on your barrel heaters and start the screw as soon as they reached setpoint instead of waiting a few hours until it “soaked in.”

The smaller the scale-up/scale-down, the more accurate it is because very large steps may not account for some differences in thermal heat transfer, and in very small screws barrel heating can contribute more of the energy input because of the small distances for heat transfer.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 50 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

Single vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreOptimizing Barrel Temperatures for Single-Screw Extruders

If barrel temperatures are set correctly and screw design is optimized, the extruder will be operating at peak performance, providing maximum profitability. If not, bad things can happen impacting quality and profitability.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

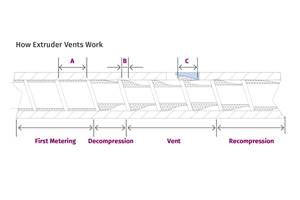

Read MoreThe Right Way to Design Vents in Single-Screw Extruders

Designing vents for single-screw extruders requires understanding of polymer flow in the screw channels. Some designs are more effective than others. Here are some guidelines.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More.jpg;width=70;height=70;mode=crop)