Extruder Inspection & Vibration Analysis Detects Problems Early, Prevents Failures

Close Up: Extrusion

Service is offered to all types of extrusion processors for all of types and makes of extruders and motors.

Henschel America is offering a reportedly unique service that combines an extruder inspection with an in-depth vibration analysis—a one-two punch that will reportedly enable problems with gearboxes, motors, screws, and the like to be more quickly pinpointed, so processors can avoid unplanned shutdowns due to catastrophic machinery failure.

This inspection/analysis service is offered to all types of extrusion processors for all of types and makes of extruders and motors, says Jerry Eber, president of Henschel America, Green Bay, Wis. (henschelusa.com). The service also can be used to identify issues with auxiliary equipment like side-feeders, melt-filtration devices, and melt pumps, among others.

About 50% to 75% of smaller extrusion houses do not have any type of vibration analysis equipment, according to Eber. He also notes that most of the companies that provide vibration analysis services lack in-depth knowledge of extruders and components such as gearboxes. “What makes this service unique is that it combines both vibration analysis and extruder inspection,” Eber states.

Besides pinpointing mechanical problems, Henschel technicians also identify operator mistakes, maintenance oversights, and the like. Common problems like misalignments or issues with the structure of the machine frame or the flooring subsurface are also quickly identified, according to Eber.

A Henschel technician evaluates the extruder while it is running, using instruments to check for vibration, temperature control, oil control, etc., while discussing issues with plant maintenance personnel and operators. If this initial inspection suggests that any part of the extruder may have problems, the technician will utilize a variety of methods to find the trouble spot. This process takes around two to five hours per extruder.

If this suspicion is confirmed, the extruder will be stopped and the gearbox (or motor, barrel section, etc.) will be opened and visually inspected. Potential remedies will be discussed.

“Motors and barrels are relatively easy to exchange,” Eber says. “Gearboxes, on the other hand, are generally custom made and thus have very long lead times. The good news is the way that modern gearboxes are built allows you to predict potential failures months, if not years, in advance. But you need to be able to understand them and know where to look. We can help the processor do this and plan a time to exchange potentially failing parts in accordance with the schedule of the company.”

Early repair means less expensive repair, states Eber. “Usually, only minor parts, mainly bearings and seals, have to be replaced when problems are detected early on,” he explains. “Early detection of potential failures also allows the extruder to keep running for an ongoing period,” continues Eber. “Production and maintenance can plan a set time for replacement or repair of the gearbox, keeping costs under control. Parts can be ordered early to shorten the time when the extruder is down.”

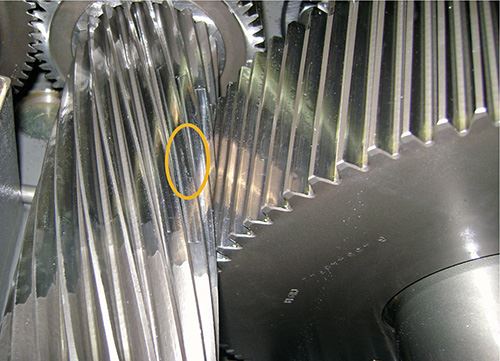

In one real-world example, Henschel technicians detected a pitting pattern in an extruder gearbox that had not been detected by conventional vibration analysis (see Fig. 1). As a result, the processor and Henschel planned a major overhaul of this gearbox. Needed parts and bearings were ordered in advance. The complete overhaul was scheduled to coincide with the processor’s planned shutdown. “If we had not done this inspection the gearbox would have completely failed in six to 18 months and cost the processor hundreds of thousands of dollars in lost production,” states Eber.

For another customer, the Henschel service detected a problem with a thrust bearing that also could not be detected with standard vibration analysis (Fig. 2). Too much sealant had blocked an oil line. The swap-out for a new bearing took a few hours. Had it gone undetected, the cost for this failure could have run into six figures, considering that the extruder would likely have been idled for months.

In yet another case, the inspection showed a pattern on the gears (Fig. 3) that suggested that the gearbox had been used to unblock frozen screws. This might not cause problems to the gears in the short term, but over the long term it will result in offset bearings and premature failure of the gears. Here, an early adjustment combined with operator training and a change in software avoided future problems and saved money for repairs.

Related Content

Die-Lip Adjustment System Relies on Motorized Actuators

Nordson will debut an automated lip adjustment system for its EDI extrusion and fluid-coating dies at the K 2022 trade fair.

Read MoreDie-Service Cart Upgraded to Handle Screws, Chill Rolls

Processing Technologies International LLC has released its next-generation flat die servicing system, the uCAMS (Universal Cleaning Assembly and Maintenance System) Plus.

Read MorePTi Makes Changes in Leadership Structure

Moves aimed at bolstering the future of the sheet extrusion manufacturer.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More