Global Competition - High Shipping Costs Give U.S. Blow Molders an Edge

When it comes to foreign competition, blow molders feel relatively invulnerable in their biggest market–bottles.

When it comes to foreign competition, blow molders feel relatively invulnerable in their biggest market–bottles. Highly commoditized applications like water bottles and gallon handleware might seem ripe for low-cost foreign production. But the expense of shipping these bulky, hollow products is an obstacle for foreign suppliers. More complex smaller bottles for cosmetics or pharmaceuticals could offer better shipping economics but their varieties of size, shape, and production volume hinders foreign entry. As a result, U.S. blow molders’ focus on differentiation and customization provides relative immunity from global competition in a range of end-use markets.

In some non-container applications like toys, hunting decoys, furniture, and commodity carrying cases, competition from abroad is stiff. A number of OEM customers for these products have relocated abroad to reduce costs.

Similar threats are also evident in blow molded consumer goods like folding tables, where “Big Box” retailers like Wal-Mart and Home Depot have exerted fierce pricing pressure. But in most industrial blow molding, the sheer size of parts makes offshore production cost-prohibitive, although some U.S. companies have sought to balance their business with lower-cost manufacturing in nearby countries like Mexico.

‘Shipping air’ doesn’t fly

The consensus is that food and beverage production for the domestic market will remain in the U.S. for the foreseeable future, so outsourcing of blow molded food containers and beverage bottles is highly unlikely. “Shipping air” is prohibitively expensive and complex supply-chain arrangements will threaten speed-to-market needs of U.S. food and beverage companies, says Chuck Arteseros, senior director of logistics at Constar International Inc., a leading bottle maker based in Philadelphia.

In fact, the food and beverage market has judged proximity to be the deciding factor in selecting a bottle or container maker. To reduce transportation costs, blow molders are moving closer to these companies–in the range of 200 to 300 miles rather than the 300- to 400-mile radius previously prescribed.

The only real threat from low-cost countries may be felt by small-bottle producers, say industry observers. Only a blip on the radar yet, certain cosmetic, amenity, and pharmaceutical applications have the potential for “outsourcing” overseas because they can be shipped more economically and in larger quantities than large bottles, says Peter Mooney, president of Plastics Custom Research Services in Advance, N.C.

These small bottles not only can be shipped more cost-effectively but they commonly require secondary decorating operations that perhaps can be done at less expense outside the U.S., says Peter Martin, president and COO of Captive Plastics, a $300-million blow molder with 15 U.S. plants. Based in Piscataway, N.J., Captive produces bottles for personal care, food, spirits, and health care but is not a major player in cosmetics. Martin has already seen direct competition in small bottles from the Far East and India and says that high labor requirements will continue to make them fertile ground for offshore companies.

Perhaps the biggest threat could come in small medical and pharmaceutical bottles, says Constar’s Arteseros. If U.S. lawmakers apply pressure on prescription drug companies to cut prices, some may move abroad to manufacture and package their products, he explains. Still, the learning curve is steep for offshore companies that must meet federal regulatory requirements, says Joe Bruchman, director of engineering and product development for SETCO, a Berry Plastics subsidiary in Anaheim, Calif., that molds small food and pharmaceutical bottles.

Smaller processors can maintain an edge over offshore competitors by exploiting product differentiation, particularly in design, asserts Greg Dean, v.p. of product supply for Plastipak Packaging Inc., Plymouth, Mich., North America’s third-largest blow molder. Finding an impregnable market niche is another strategy. An example is Classic Containers, Ontario, Calif., a $22-million molder of bottles (0.25 oz to 1L) for premium personal-care products such as high-end shampoos. Production of these highly decorated, low-volume bottles (up to 100,000 units/yr) is hard to replicate cost-effectively overseas, says v.p. Ernie Hernandez.

The Mexico option

In consumer and industrial markets, the bulkiness of typical hollow parts like auto fuel tanks and ducts, tool boxes, and storage containers make them more costly to produce abroad. Yet there are pockets of these markets where diversified blow molders like Flambeau Inc., Middlefield, Ohio, and Custom-Pak Inc., Clinton, Iowa, have felt global pressure.

Flambeau, a $125-million contract manufacturer of automotive ducting and appliance, power-equipment, and hardware parts, reports competition from Mexico and China. Since many of its products require assembly and some other secondary operations, the company is more susceptible to offshore threats, says president Jason Sauey. A big product line–hunting decoys–has been relocated exclusively to a plant in Mexico because of labor-intensive operations like painting. Flambeau’s strategy is to apportion other labor-intensive business to the Mexican plant. This balancing act makes the company as a whole more competitive against overseas companies.

Custom-Pak, a $120-million blow molder of components and enclosures for appliance, medical, automotive, agricultural, lawn/garden, and electronics industries, also feels pressure from China, India, and Southeast Asia due to its relatively high labor requirements. Ten years ago, the company opened a plant in Mexicali, Mexico, to make products for that region and the southwestern U.S. While offering lower manufacturing costs, the Mexican operation’s primary advantage is its location close to growing markets, according to chairman and CEO Dick Olsen. Custom-Pak also feels it can be more competitive by identifying labor-intensive products that are more suitable for production in Mexico.

Custom-Pak has no plans to locate plants outside North America. But to counter the “China threat,” the company licensed some of its processing technology in 2003 to blow molder Nadfinlo Plastics Industry in Hong Kong. The independent arrangement results in royalty fees for Custom-Pak for many products that are exported back to the U.S., says Olsen. Such licensing arrangements give the company exposure in competitive low-cost markets.

Blow molded consumer goods such as folding tables and outdoor storage furniture have been produced in China since 2003 by Lifetime Products Inc., Clearfield, Utah. Its wholly owned plant in Xiamen, China, produces many of Lifetime’s high-volume, low-end products such as small HDPE folding tables. These are labor-intensive to produce and easy to ship to the U.S. and Europe, says general manager Bob Adams. He adds that overseas competition in such entry-level products, plus intense pricing pressure from domestic Big Box retailers, dictates having an operation in China. A general rule, says Adams, is that products that don’t ship well and whose manufacturing can be automated to minimize labor should remain in the U.S.

Related Content

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreHow to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

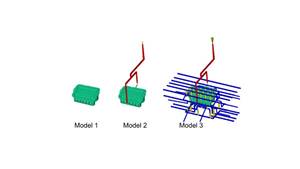

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

Read MoreTake Time to Save Time: Five Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these five steps in the design phase can save three weeks or more in an overall tool build.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

(2).jpg;maxWidth=300;quality=90)