News in Hot Runners & Tooling At Fakuma 2014

CLOSE UP: TOOLING

Novelties included variable-pitch manifolds, mold servo controls, 3D printed plastic mold inserts, and flexible/formable cooling channels.

Just a year after the mammoth K 2013 show in Dusseldorf, Fakuma 2014 in Friedrichshafen, Germany, presented a substantial crop of new developments in hot runners and tooling. Among these were an unusual "variable-pitch" hot-runner manifold system; a mold controller for all sorts of servo movements—not just valve pins; 3D printed plastic mold inserts; and flexible, conformable cooling channels.

HOT-RUNNER NOZZLES & CONTROLS

Valve gates were especially prominent among the new developments at the show:

• Ewikon (U.S. office in Rockford, Ill.) introduced the HPS III-FleX manifold system with a novel "variable-pitch" design. The system combines a linear main manifold with two side manifolds of the same length. The connecting points utilize a special pivot joint technology that allows the side manifolds to be repositioned within a defined angular range. Thermal expansion seals the joints.

The FleX system is designed for two-cavity tools used in prototyping or short-run production and standard configurations can be shipped within 24 hr (another new feature). It comes with flow channels of 4- or 9-mm diam. and utilizes HPS III-S standard screw-in nozzles with open tip or valve gating.

Other news from Ewikon includes the new-generation HPS-C controllers, which replace the previous range. Said to be faster and easier to use, the new units are equipped with more safety features and are fine-tuned for small nozzles. They come in rack-mounted HPS-C-Slot versions for two to 24 zones and free-standing HPS-C-Pro touchscreen models (stationary or wheeled base) for 12 to 192 zones. Pro versions have a Mold Wizard for easy startup and configuration, sequential startup, operator ID, early leak detection, automatic mold recognition, tool graphics with real-time data overlay, Mold Doctor mold-defect analysis, data logging, and thermocouple virtual "rewiring" to correct wiring errors. These features are also available in Slot versions with an optional touchscreen.

In addition, Ewikon is now offering a device it has used internally for years—the MWB 100 mini fluid-bed cleaning oven. Operating at up to 450 C (842 F), this portable unit holds up to 24 small tips.

• Gunther (U.S. office in Hoffmann Estates, Ill.) exhibited several products first introduced at K 2013: energy-saving, slimmer BlueFlow nozzles in a range of sizes; OktaFlow multitip nozzles with up to eight tips in a radial or linear arrangement; and electric valve gates in three versions: servo-driven (variable-speed), electromagnetic (single-speed), and stepper-motor (individually controlled pins).

• Hasco (U.S. office in Fletcher, N.C.) brought out a single-needle valve-gate (SNV) unit that’s said to be more compact than previous units. This ready-to-install, all-in-one unit comes with hydraulic or pneumatic actuation located on the back of the unit, so there is no difference in installation space requirement. It can use Techni Shot Z33 series nozzles, suitable for engineering resins, with bore sizes of 6 or 12 mm. Five needle diameters are available, along with needle strokes of 8 to 12 mm.

In addition, Hasco’s Multimodul circular four-nozzle unit now uses leak-free threaded nozzles rather than a pressure fit.

• Heitec, represented here by Technoject Machinery Corp., Bolton, Ont., showed off its new Free-Flow valve-gate nozzles that have unrestricted melt flow through the nozzle body to avoid cosmetic defects and stresses formed by melt flowing around the pin and then knitting after the gate (see June Keeping Up section).

• HRSFlow of Italy (N. American office in Windsor, Ont.) has updated its Flexflow hardware and control software. Introduced at the K 2013 show in Dusseldorf, Flexflow is an electric valve-gate system with independent servo control of each valve pin’s speed, force, and position. It’s aimed at large, thin-walled automotive parts. In addition to the original "lateral" arrangement of nozzles and servo motors, there are now "on plate" and "on manifold" options for servo placement. The "on plate" solution allows for cooling the plate so that all servos are at the same temperature. New easy-to-use software for the touchscreen controller includes safety features that ensure, for example, that the system will not operate if the heating is not turned on, and the valve pins cannot move if the operator gate is open.

• Incoe, Troy, Mich., presented a new application for its SoftGate valve-gate sequence control with hydraulic control of pin velocity to control the initial rush of melt on valve opening. Originally, this system was designed to prevent "hesitation" marks for improved surface appearance in large parts. At Fakuma, Incoe showed how smooth flow throughout the mold is also valuable in parts with in-mold decorative films (IMD), to avoid ruffling the film.

• Männer (U.S. office in Lawrenceville, Ga.) had two updates on existing nozzle designs. One is a modification of its Slimline valve-gate nozzle to provide improved temperature profile. This slender design ( 8 mm diam.) allows for tight cavity spacing. Nozzle lengths now extend to 204 mm (vs. 129 mm previously). Also new is the MCN-P Combi Nozzle Packaging, a modification of an existing design that takes higher pressure (3000 bar, 43,530 psi) for thinner-walled packaging products. Another new feature is lengths up to 404 mm for inside gating. The nozzle has interchangeable tips.

• Mold-Masters Ltd., Georgetown, Ont., showed several new developments. As reported in last month’s Keeping Up section, these included Fusion Series G2 F7000 nozzles, the largest in the Fusion range, with bore sizes up to 22 mm and lengths to 1000 mm. Also new were an upgraded Melt Cube side-gate system for medical parts; new EcoDisk ceramic pad that saves energy in Sprint hot-runner systems for closures; and TempMaster iM2 temperature control integrated with machine controls.

OTHER NEWS IN TOOLING

An interesting development from Husky Injection Molding Systems Ltd., Bolton, Ont., addresses the trend toward electric servo-powered actions in molds. "It may scare some moldmakers, but we see the all-servo mold becoming more and more common," said Craig Reynolds, director of business development. Reflecting that view, Husky is coming out with an extension of its Altanium Matrix2 hot-runner controller, a new module called Altanium Servo Control. Beyond controlling just hot-runner valve-pin movements (and temperatures), it can control speed, positioning, and sequencing of any servo actions in the cold half—such as unscrewing or collapsing cores, slides, stack rotation, and coining movements.

The prototype controller shown at Fakuma had a scrollable, icon-based "home" screen, similar to a smart phone, that makes it easy for the user to select the type of control function to configure. Servo axes are divided into "horizontal" and "vertical" axes— parallel or perpendicular to the clamping axis. The servo module can handle up to six axes plus one axis of synchronous valve-stem movement.

Meanwhile, this year Husky plans to develop a water manifold with sensors to further extend the Altanium system’s capabilities to include monitoring/control of cooling-water temperatures.

In another sign of the times, Hasco showed off its developmental project aimed at offering 3D printed plastic (ABS or nylon) core/cavity inserts for prototype and, ultimately, production molds. The materials can be filled with copper additives to promote heat transfer. Hasco is working with Stratasys Ltd., Eden Prairie, Minn. (stratasys.com) to develop inserts that can be produced quickly to speed development projects or time to market. They could be used with Hasco K3500 molds designed for quick-change inserts.

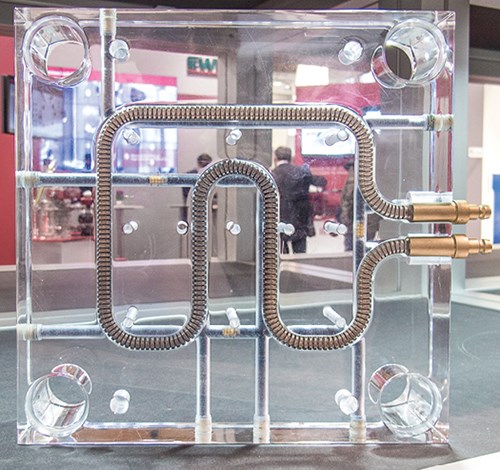

An intriguing addition to Hasco’s ever-growing range of standard mold components is Z976/977 TempFlex flexible cooling channels. Made of stainless-steel corrugated tubing, they are laid into channels milled into the surface of a mold plate. They can bend to conform to almost any curved or angled shape and can extend across pockets without leaking. Radiused corners with these tubes reportedly provide less pressure drop. The bore of the corrugated tube provides turbulent flow, Hasco says.

Other new mold components from Hasco include Z9642 diverter elements for cooling circuits that are much thinner than before. They pass water from one insert to another without drilling extra holes in plates.

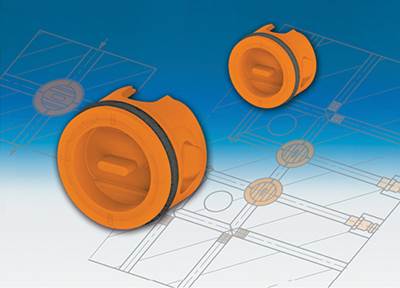

New A 4300 permanent magnets are used to magnetically secure metal inserts in molds where they cannot be held in place reliably by other means. These heat-resistant magnets have brass housings so they won’t magnetize the mold plates and turn them literally into "dust magnets."

New Z160/161 thread adapters for ejector assemblies replace the short mounting thread in the ejector package with a longer holding thread, ensuring reliable transmission of ejection force.

New K42 wide risers for ejector plates are thicker to provide greater support and permit reduced ejector spacing.

Z1215 resin thermal insulation strips, introduced at K 2013, are now being used to insulate around the outside of the mold plate, not just in the back.

Hasco is partnering with B&R GmbH in Germany to offer the Clever Mold System, a quick-clamping mold system. It integrates all the standard components of the mold into the clamping device, which remains in the machine. The tool consist of just an ejector assembly and the molding plates. Its weight is thereby reduced by up to 60%. A handwheel is used to adjust the clamping bars with special contours for attaching the mold. A coupling for cooling is also part of the CMS that remains mounted in the machine. CMS so far has been made compatible with Arburg, Engel, and Wittmann Battenfeld injection machines.

DME Europe (U.S. headquarters in Madison Heights, Mich.) announced a new sister company, Turad s.r.o. in the Czech Republic. Acquired last May by DME parent Milacron LLC, Tirad specializes in custom mold bases, plates, and frames for multicavity injection molds used in medical, food and beverage caps, and PET preforms. This brings DME into new application areas—in North America as well as in Europe.

Related Content

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreYoung Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

Read MoreWisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreRead Next

News in Hot Runners & Tooling at K 2013

Molds that break speed records for specific applications; hot runners for medical, packaging, and automotive parts; temperature and valve-gate controllers; and standardized mold components constitute a large grab-bag of news in the tooling category for injection molding at the Dusseldorf show.

Read MoreNews in Hot Runners & Tooling at K 2013

Molds that break speed records for specific applications; hot runners for medical, packaging, and automotive parts; temperature and valve-gate controllers; and standardized mold components constitute a large grab-bag of news in the tooling category for injection molding at the Dusseldorf show.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

(2).jpg;maxWidth=300;quality=90)