NPE 2009 News Flash

An Advance look at some of the news awaiting you in Chicago next month.

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

- Postindustrial

- In-Mold Decorating

- Extrusion

- Additives

- Single-Screw Compounding

- Resin Conveying

- Stretch Blow Molding

- Drying

- Tooling

- Engineering Resins

- Pipe, Profile & Tubing Extrusion

- Blow Molding

- nanocomposites

- Materials

- All Electric & Hybrid Machines

- Processes

- Testing

- Heating & Cooling

- Barrier Blow Molding

- Recycling

- sustainability

- Postprocessing

- Mold Simulation

- Compounding

- Purging Compounds

- Sheet Extrusion

- Film Extrusion

- Processes

- Injection Molding

- Postconsumer

- Molds & Tooling

- Multiscrew

- Hot Runners

Injection Molding

Hybrid Press Has Electric Clamp

New injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn. Its Allrounder H/Hidrive series from 66 to 352 tons is suited to shorter cycles. The series has hydraulic injection units from the Allrounder S Advance line, coupled with an accumulator and a servo-electric screw drive for plastication. The servo-electric toggle clamp comes from the all-electric Allrounder A series.

Charging of the hydraulic accumulator is dynamically regulated, meaning that the pressure level is automatically adapted to the actual demand, so as to use the minimum required pump capacity. The machine reportedly delivers energy savings up to 40%.

Hot Runners for PLA

D-M-E Co., Madison Heights, Mich., will show its brand-new Eco-Smart standard hot-runner system for PLA and other biopolymers. It uses corrosion-resistant components to resist the acidic properties of PLA and its tendency to plate out acid residues on the walls of the molding system. It also has specially designed nozzle tips to minimize shear and provide high cooling capacity; low-pressure, low-shear channels; and a thermal profile to counteract PLA’s temperature sensitivity.

Structural Foam for Pallets

A new line of structural-foam machines is dedicated to pallet making in terms of shot size, plasticating capacity, and overall output. The Lumina Pallet System from Wilmington Machinery, Wilmington, N.C., costs 20% to 40% less than general-purpose structural-foam machines.

Wilmington also improved its G-P structural-foam systems with a simplified nozzle/manifold system, larger platens, and electric extruder drive.

3D Simulation Software Gets Enhanced Capabilities

The latest 3D injection molding simulation software from Vero USA, Wixom, Mich., is now fully integrated with the company’s CAD modeling, mold design, and mold machining tools, and it has the capability to model two additional process techniques. New Visi Flow 17 simulation has enhanced CAD capability that makes evaluating design changes easier and faster. Model preparation and analysis time is reduced through the improved Visi Flow mesh wizard, including a new feature-recognition program for runners and cooling channels. The software now can simulate overmolding and crosslinking of resins such as LSR.

Thanks to full integration, moldmakers can seamlessly navigate through Visi Modeling, Visi Mold, Visi Flow, and Visi Machining modules. Vero says it is the first to offer flow simulation software fully integrated with surface- and solid-modeling tools, comprehensive 2- to 5-axis machining with high-speed routines, 2- and 4-axis EDM, and a mold-design package.

Hot-Runner Nozzles Have ‘Diamond’ Coating

A new line of hot-tip nozzles for engineering resins, as well as a series of energy-saving open-tip or valve-gate nozzles for general-purpose use are new from Yudo Co. Ltd. of Korea (represented here by Yudo Inc, Plain City, Ohio). The IO series hot-tip nozzles have been revamped for improved heat conductivity and wear resistance. The torpedo-like tip is made of hardened steel (62 Rockwell C) as well as copper for conductivity and a special diamond-like coating for wear resistance. The open nozzle tip can handle a 30% glass-filled PA 66 resin at

536 F.

Yudo also is replacing its Bala line of open and valve-gated nozzles with its new WINA system, which reduces heating requirements up to 40%. The new nozzles feature a spiral open gate for better mixing, and the various gate shapes have been optimized for more uniform heat balance. Front access allows easy maintenance.

Static Charger for IML

The news from Simco at the show will be its PrecisION high-voltage power supply. This is said to be the smallest such power supply available for static charging of in-mold labels and is so lightweight that it can be mounted directly on the label feeding robot’s end-of-arm-tooling. It has adjustable output voltage from 8 to 18 kV and can be switched on/off remotely.

Nozzles for Small Parts

A new line of miniature nozzles for high-cavitation packaging or medical parts will be introduced by Mastip Inc., Slinger, Wis. Its new MJ-09 nozzles reportedly provide improved cooling, and their small gate/bore detail suits them to tight gating locations. Users can choose from an open-nut, multi-hole torpedo tip or extended-tip gating options. Front-loading heater, thermocouple, and tip allow easy access.

New Hybrid Presses

A hybrid injection machine line that allows users to overlap process functions is new from Negri Bossi Inc., New Castle, Del. The new Janus line features direct-drive servo-electric actuators for clamping and plasticating, plus a “smart pump” hydraulic system with accumulator for fast injection. Hydraulics also power the ejector, core pull, and carriage movements. The company says that energy usage is similar to that of its all-electric Canbel line. Janus will be offered in clamp sizes from around 176 to 990 tons and shot capacities from 3.8 to more than 225 oz. The new control panel has a larger and brighter LCD and digital wireless communication capability.

Extrusion

Twin Carbon-Fiber Air Rings Optimize Air Flow

The new CR Twin dual air ring, introduced by Macchi SrL of Italy at the recent Plast show in Milan, will be shown for the first time in North America at NPE next month. Macchi (U.S. office in Gainsville, Ga.) previously built dual air rings, but this is its first with carbon-fiber composite housings. The CR Twin housing reportedly allows smoother internal air flow than cast aluminum housings and weighs far less, making it easier to raise and lower. The composite housing is also naturally insulating, so it significantly reduces condensation from low-temperature air and doesn’t require rubber insulation.

The CR Twin has a fixed single-lip air ring below and a movable dual-lip air ring above with optimized lip geometry for better bubble stability and a wider range of BUR than is typical for dual rings, Macchi says. The upper ring is motorized for automatic height adjustment. At the Milan show, Macchi demonstrated BUR ranging from 3.8:1 to 1.8:1. The CR Twin is available for up to 350-mm-diam. dies.

First U.S. Show for Layer Multiplication

Layer multiplication hardware has never been shown in the U.S. before. Extrusion Dies Industries LLC in Chippewa Falls, Wis., will display a commercial 84-layer system for the first time at NPE. Layer multiplication can be used with flat dies for cast film or sheet of almost any width. EDI will also show microlayer film samples and test results from its microlayer development lab.

Layer multiplication involves stacking coextruded layers to increase a film’s impact strength, elongation, and barrier properties with minimal material. Many microlayers of barrier and tie resin, for example, can increase oxygen barrier three to five times more than the same amount of barrier resin in a single coextruded layer, according to independent lab results. EDI sold its first two commercial-scale microlayer systems—both for cast film—this year. Previous sales were lab systems. EDI’s layer multiplying technology is licensed from Dow Chemical Co., Midland, Mich.

New Direct-Drive Extruders

Two new direct-drive extruders will be shown at NPE by American Kuhne Inc. Ashaway, R.I. One was designed and built by Kuhne using a synchronous, permanent-magnet torque motor for normal screw speeds of 100 to 150 rpm, rather than the very high speeds and throughputs for which direct-drive models are used in Europe. The advantages of direct drive are said to be less machine wear and maintenance, 10% to 15% higher energy efficiency, and cleaner operation without a gearbox for food and medical packaging.

American Kuhne will also show a German-built direct-drive, high-speed model in the U.S. for the first time. It’s designed for extruding PS and PP sheet at 1200 to 1500 rpm for thermoforming.

(401) 326-6213 • www.americankuhne.com

Air/Water Cooling Die Doubles PE, PP Pipe Output

The commercial version of the KryoS die from Cincinnati Extrusion GmbH in Austria (U.S. office in McPherson, Kan.) will be shown for the first time in Chicago next month. As we described last December, a prototype was shown at an open house in Vienna last year and was since installed at a customer for long-term production testing. The KryoS die is water-cooled to reduce the melt temperature in the die and also sucks ambient air through the pipe to cool it from the inside. The combination of cooler melt and internal air cooling can either double throughput of polyolefin pipe with the same downstream cooling or reduce the length of downstream cooling by half for the same output as before, the company says. HDPE pipe exits the die at 330 to 350 F, about 20% cooler than normal, so the pipe shrinks less and hardly sags. Hot exit air can also be recirculated to preheat pellets in the hopper and reduce the energy needed by the extruder.

The die will be available in five sizes for pipe diameters from 3.5 to 78 in. and outputs up to 7700 lb/hr of HDPE. Overall energy savings of up to 30% are claimed.

Nano-Grains Strengthen Pipe & Tubing

Guill Tool & Engineering Co., W. Warwick, R.I., has two novel developments to talk about. One that won’t be on display is a flow-striping feature that splits the melt into ribbons, laminates the ribbons together, and then repeats the steps. This principle can create “nano-sized grain features,” according to Guill’s patent application (U.S. 20080315449). When the stripes, ribbons, or nano-grains are combined with Guill’s patented rotating die components, the effect is to wrap material into a pipe or tube with higher burst strength than is obtained from a conventional tube of the same resin.

Guill will be showing its new Micro Adjust mechanism for small tubing, which reportedly provides roughly eight times finer adjustment than conventional four-bolt die-centering devices. Micro Adjust (patent-pending) is combined with Guill’s four-bolt Feather Touch die to make centering easier. It prevents over-adjustment by tuning a die with only two bolts, eliminating the need to loosen the two opposing bolts.

High-Frequency Ultrasonic Thickness Gauge

LaserLinc Inc. in Fairborn, Ohio, is introducing the UltraGauge+ ultrasonic thickness gauge for tubes. In 2006, LaserLinc acquired the ultrasonic wall-thickness measuring technology and product line of On Line Controls of Hudson, Mass., whose products LaserLinc had previously distributed and serviced. The device can make over 2000 wall measurements a second vs. 400/sec before. It uses a higher-frequency signal, which doesn’t penetrate as deeply into the plastic, so the echoing ping travels back faster, allowing more measurements. It can measure pipe or tube of most plastics from as thick as 1 in. down to 0.001 in. (or 0.0005 in. for fluoropolymer).

Supervise Resin Savings For Blown Film

One recurring theme at NPE will be material savings. One example is a new Total Control System (TCS) for blown film being introduced by Addex Inc., Stoughton, Mass., which reportedly can save 7% to 13% of resin usage, depending on the gauge controls. TCS controls include Addex’s new Gravex continuous gravimetric blending system, that controls average film thickness—the first such system from Addex. TCS also replaces individual controls on Addex’s IBC or air-ring based automatic gauge control for TD thickness; and Addex’s patented digital IBC control system for bubble diameter and layflat width. The TCS control thus integrates all three functions with new graphic displays (photo). The new TCS software is included in the price of the individual components and can be upgraded incrementally.

Conair of Cranberry Township, Pa, also will introduce its first gravimetric extrusion control for consistent dimensions and weight per length. Its TrueWeigh system utilizes a new TrueBlend EXT gravimetric blender. Conair will also introduce the ScrapSaver in-line film scrap reclaim system, which can handle up to 25% scrap without surging or clumping, the company says.

Blow Molding

New Coex Wheel Models

Smaller wheel-type extrusion blow molders designed for coextruded containers come from Graham Engineering Corp., York, Pa. Its Mini Wheel line, which started with a 12-station unit, includes new nine- and 10-station versions. These give small and mid-sized molders an alternative to a five- or six-parison, double-sided shuttle machine.

Dual-Parison System For Small Bottles

A dual-parison wheel-type blow molder for small bottles (up to 0.5 liter) will be introduced by Wilmington Machinery, Wilmington, N.C. Its 50-cavity Small Bottle (SB) system can produce monolayer bottles or coextrude up to six layers. It can process more than 2000 lb/hr of HDPE and up to 18,000 bottles/hr, depending on size. The system is supplied with multiple sets of molds, bottle conveying, and trimming. Wilmington will also roll out an updated version of its Series V line for large bottles.

New Inspection Tools For Bottles

AGR Topwave LLC, Butler, Pa., says its latest PETWall Profiler system offers in-machine wall-thickness profiling for PET bottles. AGR will demonstrate a PETWall Profiler system using new camera inspection software that checks the base, sidewall, and seal surface for defects. The company will also introduce a line of vision products for PET and polyolefin bottle testing, though no details were available before showtime.

Compounding

Extensional-Elongational Mixing Rotor

Xaloy Inc. in Newcastle, Pa., has developed the first commercial version of a new mixer, under license from Stratek Plastic Ltd. in Wallingford, Conn. Called the nXmix, this separate 10:1 L/D device mounted on its own stand attaches to the end of any single- or twin-screw extruder. It consists of a conical rotor covered with a repeating pattern of pockets, similar in concept to the Cavity Transfer Mixer, but rotating at up to 320 rpm. The pattern on the rotor repeatedly stretches and compresses the melt hundreds of times in the highly cooled barrel, within a residence time from 15 to 40 sec. Extensional (or elongational) flow achieves both distributive and dispersive mixing with less heat and shear than other mixers, Xaloy says.

This type of mixing can enhance dispersion of small amounts of hard-to-mix additives like nano-materials or colorants and can help achieve high filler levels. Typical uses are in-line compounding of blown film, mixing heat/shear-sensitive materials like PVC, or improved mixing in place of high-mesh screen packs used in film or profile extrusion. Xaloy will display a cutaway model of nXmix. The device is available now for throughputs up to 100 lb/hr, and larger units for more than 1000 lb/hr are planned to be offered soon.

New Sizes of High-Output Kneaders for Polyolefins

NPE will see the North American debut of the newest MX kneader from Buss AG in Switzerland (U.S. office in Carol Stream, Ill.). The MX kneader adds a fourth flight and a fourth row of mixing pins in the kneading chamber and has significantly increased screw speed for 2.5 times higher throughputs of polyolefin wire and cable compounds compared with the previous three-flight kneader of the same diameter. MX kneaders use high-speed direct-drive motors for energy savings of 10% to 30% over previous models. Potential applications also include masterbatches of carbon black and other additives. An MX 105 model for up to 4000 lb/hr will be shown.

The MX was first shown at the K 2007 show in Germany, but Buss has since added two larger machine sizes—MX 125 for up to 7000 lb/hr and MX 140 for up to 9900 lb/hr.

Additives

Additives from Abroad

At NPE, North American processors will have an opportunity to familiarize themselves with additives from Asian and European producers they may not know. For example:

- A.F. Supercell Co., Ltd. of Thailand will show off chemical blowing and nucleating agents and masterbatches.

- Samwha Corp. of Korea highlight its color and additive masterbatches and custom compounds.

- 3V Inc., Georgetown, S.C., is a branch of 3V Sigma of Italy, which produces antioxidants, uv stabilizers, flame retardants, and optical brighteners.

+66 (662) 634-1323-5 • www.afsupercell.com

+82 2-2671-0477 • www.sam-chem.com

(843) 546-8556 • www.3v.com

New Hollow Microspheres

Two firms will show off improved grades of hollow microspheres. Potters Industries, Inc., Berwyn, Pa., will introduce new lightweight grades of Sphericel hollow glass spheres—34P30 (0.34 g/cc) and 25P45 (0.25 g/cc) for use in nylons, PBT, and PP.

Meanwhile, Expancel/Eka Chemicals Inc., Duluth, Ga., is highlighting new grades of Expancel expandable polymer spheres with higher temperature resistance.

Materials

Non-Halogen FR Nylon With High Track Index

Chemlon 225 GVNH is 25% glass-reinforced nylon 6 rated UL 94V-0 at 0.032 in. (0.8 mm) without containing halogen or red phosphorus. Introduced by Chem Polymer, a unit of Teknor Apex Co., Pawtucket, R.I., this said to be one of the few glass-filled, non-halogenated FR nylons in North America. Its comparative tracking index (CTI) of 600V is said to be more than double that of a comparable halogenated FR nylon. It is also 14% less dense than halogenated compounds.

Biopolymers & Degradables Take Center Stage

Plastics made from renewable resources and/or biodegradability and compostability will be major themes in the materials exhibits at NPE. More than a dozen booths will feature such materials and more will offer additives and processing equipment tailored for biopolymers. Some 39 companies, government agencies, and industry consortia will make conference presentations on the subject. Here are a few of the new products to be highlighted:

- Cereplast Inc., Hawthorne, Calif., will introduce two new starch-based compounds: Compostable 5001 for foam sheet extrusion and thermoforming into food trays and containers; and Compostable 3000 for blown film. Also new are two 70/30 PP/starch blends—Hybrid 101, offering good impact resistance for durable applications; and Hybrid 103 with high flow for injection molding.

- Felix Composites, Saint-Hubert, Que., is a producer of TPEs that is now making “oxo-bio-degradable” compounds of PS and PE and also biodegradable compounds of 40% starch and 60% PE or PP.

- Kureha America, Inc., Naperville, Ill., is introducing its Kuredux polyglycolic acid (PGA). PGA is a naturally occurring and biodegradable chemical, but Kuredux is derived from natural gas. As we reported in May of last year, it is a high-barrier material suitable for use in multilayer PET bottles. Kureha is building a plant in West Virginia that is due on line next year.

- PSM North America, a new venture of Teinnovations, Warrenville, Ill., is introducing “plastarch” material (PSM), a thermoplastic starch compound made by PSM Hong Kong. Some compounds and sheet are also produced in the U.S. PSM is available in several grades for injection molding, foams, extrusion/thermoforming, and blown film. The newest grade, PSM HL-301, is designed to be run as a stand-alone resin for blown film.

- Teknor Apex Co., Pawtucket, R.I., will introduce its new bioplastics division and its first products based on Cerestech’s thermoplastic starch (TPS) technology. Teknor has exclusive worldwide rights to produce blends of TPS and bioplastics like PHA or PLA, as well as polyolefins. Its first commercial products will be TPS with LLDPE, LDPE, and HDPE. Fully biodegradable blends are in testing.

- Telles will show off injection molding and sheet extrusion grades of its Mirel PHA bioplastic. Its commercial plant is expected to be running this fall.

- Zhejiang Hangzhou Xinfu Pharmaceutical Co., Ltd. of China is introducing to the U.S. its poly-butanediol succinate (PBS). It is fully biodegradable and is based on succinic acid, a naturally occurring fermentation byproduct (present in wine and beer) and butanediol (based on petrochemicals). PBS is used in agricultural and packaging films, bags, boxes, bottles, and molded medical parts and disposable tableware.

New Purging Agent for Blown Film & Sheet Lines

Purgex 461 Plus is a new purging compound designed specifically for cleaning blown film and sheet lines. Introduced by Neutrex, Inc., Houston, it is a special blend that can clean the extruder, screen pack housing, die, and manifold. In some cases, it does not require removing the screen pack. The company says it is very effective in purging the newly popular biodegradable and compostable polyethylene compounds. Supplied as pellets, the purging agent is a blend of LLDPE and non-abrasive, FDA-approved ingredients. It can be used at 250 to 450 F.

Heating/Cooling

Larger & ‘Eco-Friendly’ Temperature-Control Units

Two new developments from Mokon, Buffalo, N.Y., include an expanded line of Hydrotherm II Plus hot-water TCUs. The company recently increased the maximum heating capacity from 9 kw to 12 kw, and the show will debut models of 18 and 24 kw. Max. pump size remains 3 hp and max. flow rate is still 60 gpm.

The second development is the arrival of Iceman central and portable chillers equipped with “green-friendly” R-407C refrigerant. It is one of several alternatives that will replace ozone-depleting R-22 (“Freon”) by next year. Existing Iceman chillers can be retrofitted with R-407C.

Energy-Efficient Cooling Technologies

Two developments in energy-efficient central chilling will be shown by Frigel North America, E. Dundee, Ill. One will be the brand-new Ecoflex chiller (photo) with variable-speed centrifugal compressor and oil-free magnetic bearings. This unique Danfoss Turbocor compressor technology has been adopted by other chiller makers because it offers substantial energy savings (depending on load), space-saving compactness, unusual quietness, and low maintenance.

Frigel is offering Ecoflex as a modular central chilling station that allows for expansion by linking together multiple modules. Frigel says Ecoflex is its “most energy-efficient product to date,” which offers “the highest efficiency available in the market.”

Frigel will also highlight at NPE another energy-saving technology based on outdoor ambient-air cooling without using a tower or chiller. As we reported in February, the latest version of this system is the Ecodry EDK, which offers enhanced overall cooling capacity compared with the previous Ecodry EDG model.

More Than a Flowmeter

Optimize your plant cooling with the new Fluid Characteristic Indicator (FCI) from Burger & Brown Engineering, Inc., Grandview, Mo. When inserted in a 1/4- or 3/8-in. diam. water line, the device displays more than just mold water temperature and flow rate in gpm. Its main function is to characterize the flow condition as laminar, turbulent, or transitional, based on temperature. Flow rate should be raised to the point of turbulent flow, which provides optimum cooling efficiency, and flow rates higher than the point of turbulent flow do not significantly improve cooling.

Material/Parts Handling

Lots of New Dryers at NPE

A number of new dryers will debut at NPE next month. Here’s a quick rundown of some of them:

- Motan Inc., Plainwell, Mich., will show the Luxor 50 (50 m3/hr airflow capacity) model in its new beside-the-press series of twin-bed desiccant dryers. The Luxor 50 and 80 have a single blower for both process and regeneration circuits, while Luxor 120 and 160 have separate process and regeneration blowers. All models dry in closed-loop mode and have stainless-steel construction.

- Shini USA, the plastics div. of Budzar Industries, Willoughby, Ohio, has added dryers to its line of auxiliaries (chillers, mold-temperature controllers, and granulators) built by Shini Plastics Technologies of Taiwan. Two types will be shown: The SCD All in One Compact Dryer integrates desiccant drying with a honeycomb rotor and two-stage conveying. Sizes range from 30 to 700 m3/hr airflow capacity. Meanwhile, the SCAD compressed-air dryer with integral conveying (photo) has a stainless-steel hopper and is designed for low headroom.

- Universal Dynamics, Inc., Woodbridge, Va., has expanded the range of dryer types it offers. The new Titan TR Series are its first desiccant wheel types and have a stainless-steel wheel canister with hook/tooth design and a Kevlar-reinforced timing belt that is said to avoid slippage and needs no lubricant. A special heat-recovery system recaptures regeneration air to save energy in regenerating the wheel. Throughput range is 15 to 250 lb/hr.

Also new to UnaDyn is a compressed-air dryer with a membrane—its AutoDry II Series, with all-stainless construction. And the new Titan TS Series twin-bed desiccant dryers (15 to 300 lb/hr) have a modular design that allows easier access to all key components. They also have stainless-steel hoppers, 20% smaller footprint than previous models, a smaller and more efficient process heater for rapid heat-up and cool-down, and basic datalogging capability as standard.

Dust-Penetrating, Non-Contact Level Sensor

What is described as a “revolutionary” technology in silo or bin level measurement will be introduced by BinMaster, Lincoln, Neb. The new 3DLevelScanner reportedly works where other level sensors have failed—e.g., with dusty materials or those that cling to the sides of bins, and situations where multiple filling sites or clumping materials produce an uneven material surface inside the bin. This patent-pending technology is said to work well with plastics in small or very large containers.

A device at the top of the bin or silo emits low-frequency sound pulses, and an array of microphones receives echoes reflected by the contents. The digital signal processor analyzes the signals and generates a 3D “map” or image of the surface that can be displayed on a remote screen. The basic configuration has single-point level measurement; surface mapping and 3D visualization graphics are optional.

Trap Angel Hair in Conveying Lines

Remove streamers or “snake skins” with the new In Line Angel Hair Trap from Lorenz Conveying Products, Cobourg, Ont. It can be positioned anywhere in the conveying line. Its clear, removable cover doubles as an inspection and cleanout port. The stainless-steel device is suitable for vacuum and pressure systems and is installed easily with compression fittings.

High-Temperature Magnets Not Fazed by Hot Dryers

“We have seen a significant increase in applications with dryers that emit temperatures up to 300 F,” says Joey Reed, product manager for metal detection at Bunting Magnetics Co., Newton, Kan. He adds that very few suppliers offer metal detectors that can take such heat. To answer this need, Bunting has come out with the High-Temperature Machine-Mounted All-Metal Separator (MMS), which mounts on the throats of extruders or molding machines and operates at up to 300 F. It can support the weight of hoppers and other auxiliary equipment. The MMS catches ferrous and nonferrous metal contaminants and rejects them by means of a fast pneumatic slide gate.

Also new from Bunting at NPE is the Continuous-Cleaning HF drawer magnet (pictured). It is designed to be self-cleaning “on the fly” with no disruption of product flow. Pneumatic cylinders fully extend the magnetic cartridges outside the drawer housing. “As our tube assemblies travel outside the housing, grommets wipe the tubes clean all the way to their nonmagnetic tapered ends,” says Rick Bigham, product manager for magnetic separation. “This ensures that each cartridge is fully wiped and prevents captured tramp iron from re-entering the housings. The standard two-row model maintains magnetic protection while self-cleaning by withdrawing one row of magnets for cleaning while the other remains in place. Three- and four-row models are also available.

Box Fillers, Part/Runner Separators & More

Three new entries will be exhibited by Dynamic Conveyor Corp., Muskegon, Mich. First, DynaCon automated box-filling systems will be introduced in over/under and in-line designs. Both allow user-defined fill rates to ensure filling accuracy to within 9 g or 0.3 oz. Filled boxes can weigh up to 200 lb. Filling can be by weight, cycle count, or weigh count. They are said to offer easy control setup, quick disconnects between conveyors, a large graphical LCD, and ability to store multiple jobs.

Second, the new DynaCon Tumbler Separators (introduced last summer) have a rotating cage with interchangeable sleeves with different hole sizes, which can be changed in less than a minute. The simple, maintenance-free drive mechanism uses a 1/30-hp, variable-speed brushless motor. New at the show will be a linear actuator option that raises or lowers the angle of the cage to optimize part/runner separation for each job. The actuator can even change the angle during the course of each separation cycle.

Third, DynaCon’s new low-profile conveyor module has a 4-in. frame height—half that of previous models—for areas with space height limitations. It is suited to removing parts from under presses, feeding scrap into grinders, or moving parts into clean rooms.

Easy-Cleaning Hopper Loader

New Feedmax B series loaders from Wittmann Battenfeld, Inc., Torrington, Conn., are completely redesigned for flexible application and easy cleanout. The top opening of the cylindrical section is cut at a slanted angle to open a greater cross-sectional area for easy access to the interior. Also, the screen is fixed to the lid and lifts out of the unit when the lid is opened. To clean the screen, the lid can be simply removed from the hinge and blown off with compressed air—no vacuum or material lines are connected to the lid.

Material inlets and vacuum outlets can easily be adapted to fit various system tubing diameters. A modular kit with two different cylinder segments allows configuring the loader for a range of throughputs. Volume capacities are from 4 to 24 liters.

Scrap Reclaiming

New Auger-Fed Granulator

The new MAS Series of beside-the-press granulators from Wittmann in Austria will be shown for the first time in North America at NPE. These are low-speed (240-rpm), high-torque (500-Nm), direct-gear-drive models, which first appeared at the K 2007 show in Germany. The granulator housing hinges open on top and also drops down in front for rapid cleanout. Since K 2007, Wittmann (U.S. office is Wittmann Battenfeld in Torrington, Conn.) added an auger-feed model (MAS2A) with a large (23.6 x 11 in.) auger trough to collect warm sprues and runners directly under a molding machine. A knife in the trough (previously optional, now standard) cuts the sprues if they try to wrap around the screw. The auger automatically reverses direction if it meets resistance. This 5.4-hp unit handles around 154 lb/hr.

Welding

High-Precision Ultrasonic Welders

Among new ultrasonic welders to be shown by Sonics & Materials Inc., Newtown, Conn., is the e-Press model, designed to provide precise, repeatable welds to the exact final dimensions of a part. The new system uses an electric stepper motor with optical encoder, a rigidly mounted booster, in-line load cell for precise welding force, and a linear ball-screw actuator. It has a Microsoft Windows software interface and programmable digital force, velocity, and distance parameters. The system reportedly welds to a depth tolerance of ±0.0003 in with melt-down velocity control. It comes in 40-kHz models with 400 or 800W power and 20-kHz models with 1200 to 3500W.

Laser Staking & Welding

A new laser staking method for fastening metal parts to plastic components will be introduced by LPKF Laser & Electronics North America, Wilsonville, Ore. Like laser welding, laser staking can join a material that is transparent to laser energy to a material that absorbs the laser beam. Both approaches deliver high repeatability, a small heat-affected zone, and low mechanical stresses. LPKF’s laser-staking tool is about the same size as an industrial screwdriver. The separate power module and controller fits in a 19-in. housing.

The company is also introducing a laser welding system for small and medium-sized batches or clean-room use. The LQ-Vario MF creates ultra-fine welding seams in the micron range, making the unit suited to micro-fluidic applications.

Related Content

K 2022: ‘All-in-One’ Bottle Tester Takes Three Measurements at Once

Delta Engineering’s new system performs simultaneous topload, height and both pressure-decay and high-voltage leak testing.

Read MoreDatacolor Launches Annual Subscription Payment Program for Color Management Software

The subscription plan is available for Datacolor Tools color QC application for plastics and other software products.

Read MoreSensors Measure Moisture in PVB Films, Pellets

NPE2024: Noncontact sensors provide a continuous, reliable reading with zero drift and no maintenance.

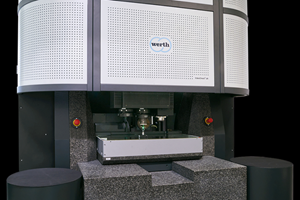

Read MoreUpgraded CT Scanning and Multi-Sensor Coordinate Measuring Machines

Werth’s TomoScope S Plus 240 systems boast more than double the measuring volume as their predecessor with almost the same size.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More