Simultaneous Blowing/Filling Process ‘Breaks Down Walls’ in Supply Chain

Amcor’s LiquiForm technology supports new ‘holistic’ on-site processing service.

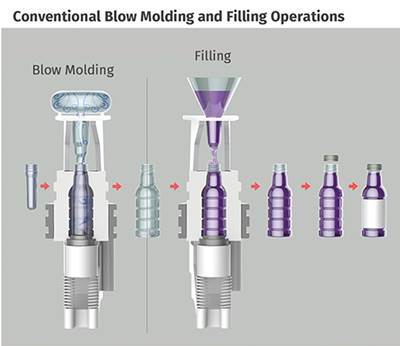

“You’ve heard of ‘through-the-wall’ bottle manufacturing? Now we’re breaking down that wall between the brand owner and bottle producer.” That’s one way that Ashish Saxena describes Amcor 360, the new “transformational packaging service” from Amcor Rigid Plastics, based in Ann Arbor, Mich. Saxena is v.p. and general manager of Amcor 360 Packaging Solutions, which is placing machines and personnel in brand owners’ and co-packers’ facilities to deliver a package already filled with liquid product, not empty bottles to a filling line. The secret is a one-step process in which the contents actually form the container.

Amcor 360, “powered by LiquiForm,” as Amcor puts it, is a service based on the patented LiquiForm process. Unveiled by Amcor in 2014, LiquiForm is a stretch-blowing process in which an injection molded preform is formed into a container not with compressed air but with the liquid contents of the bottle (see Sept. ’14 Starting Up and April ’15 feature for details). The first commercial application of LiquiForm was announced last February (see March ’18 Starting Up) and Amcor 360 was introduced in October.

BETTER BOTTLES, LOWER COST

Combining the bottle blowing and filling steps into one simultaneous step utilizes less equipment, less floorspace, and less energy. Saxena notes, “One co-packer tells me he has thousands of square feet dedicated to storing ‘air’—empty bottles—which is incredibly costly. The ability to run from liquid to finished goods frees up space for manufacturing and eliminates incoming freight.”

LiquiForm has proven ability to save costs in two other ways, as well. Forming the bottle with liquid instead of air reduces energy consumption by 40-60% and allows for faster forming times, potentially cutting overall cycles by 25-40%, according to Richard Sieradzki, v.p. and general manager of Amcor’s LiquiForm Group, which licenses the technology. He notes that the time saved could be used for capping the filled container. In addition, forming containers with liquids enables more uniform material distribution, allowing for lightweighting. In the first two applications—one already commercial and one soon to be so—material savings were as much as 20%, Saxena says.

Another key benefit is two to three times better definition of mold details. LiquiForm Group has established this with a test mold incorporating various textures and details. The process produces improved transfer of embossed mold details that mimick glass, as in the liquor bottle shown above.

The Liquiform process reportedly lends itself to a wide variety of liquid foods, beverages, and personal-care products. Sieradzki notes that the LiquiForm Group has tested the process using liquids with viscosities from 1 cp to 10,000 cp and plans to experiment this year with viscosities up to 50,000 cp, in the range of ketchup and hair conditioners. The Group has used the process to make bottles from 200 ml to 1 gal capacity and plans to go both larger and smaller. It has made bottles as light as 8.5 g for still water and as heavy as around 100 g. Bottle shapes have ranged from simple rounds to complex shapes.

LiquiForm Group has used the process with PET and HDPE. Yoshino Kogyosho, Japan’s largest bottle maker, has used the process with PP bottles. Sieradzki sees future potential for a Liquiform machine able to use all three materials.

Amcor Rigid Plastics is one licensee of the LiquiForm technology; others include major bottle blowing, filling and capping machinery makers such as KHS, Krones and Sidel, as well as the Japanese processor Yoshino. Amcor developed the first commercial machine for the process, as well as the first commercial product, Nature’s Promise liquid hand soap. A second, similar application is coming “very soon,” Saxena says, and still another liquid soap project should reach fruition this year.

What’s more, Amcor 360 is working on a still-water application to be released this year. This will be followed by flavored water and isotonic beverages. “This will be a huge step forward to significantly larger volumes for the LiquiForm process,” Saxena says. Initial uses are medium-volume, he says, using a linear shuttle reheat stretch-blow machine. But beverage applications will be able to take advantage of high-output rotary machine platforms.

COMPLETE PACKAGING SOLUTION

While the first LiquiForm hand-soap applications are being produced at existing Amcor facilities, beverage production will follow the new Amcor 360 model. Saxena describes this as a “holistic” packaging solution, in which Amcor 360 will provide the machine and operate it at the customer’s location, supported by “best-in-class” preform and bottle design, a proven manufacturing “recipe” for the product, and a commitment to continuous improvement of the process.

This supply-chain simplification means that customers don’t have to invest capital in equipment, don’t have to worry about finding or training people to run it, don’t need freight services or storage space for bottle inventory, and can improve their sustainability profile through energy and material savings in package manufacturing and logistics.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreIn Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

Amcor Launches First Commercial Container Using Its LiquiForm Technology

First commercial PET container from Amcor’s simultaneous stretch-blowing and filling process.

Read MoreDeveloping Tomorrow’s Containers: Inside Amcor’s R&D Center

How award-winning package design, full-service laboratory facilities, and game-changing process development support a world-class injection and blow molder.

Read MoreBlow a Bottle with Liquid Instead of Air

New technology--to be made widely available--blows and fills bottles in the same step.

Read More

(2).jpg;maxWidth=300;quality=90)