Optimize Barrel Temperatures For Barrier Screws

Extruder operators often don’t compare the barrel-zone temperatures to the recommended processing temperature for the resin being run.

Extruder operators often don’t compare the barrel-zone temperatures to the recommended processing temperature for the resin being run. It isn’t uncommon to see extruder barrel-temperature zones set lower than the desired melt temperature. When this type of operating condition is used, control of the extrudate temperature is totally dependent on screw geometry and the viscous heat developed from shear generated by channel depths, flight clearances, and screw speed.

This is especially problematic when the extruder is using a barrier-type screw, which is commonly used in most extrusion processes to achieve optimum output and performance. Barrier screws are high-performance screws, which need finer tuning of barrel-temperature zone profiles.

Studying the heater-zone layout and how the zones are located in relation to the different sections of the screw will help determine the proper zone settings. The general configuration of a single-screw extruder with 24:1 to 30:1 L/D and a barrier screw is to have a feed section, barrier section, and metering section, with a total of five temperature zones.

Starting with the die, both the die and adapter zones should be set at the resin manufacturer’s recommended melt temperature. The cast-iron feed-throat section of the extruder should then be set to a temperature which is warm to the touch (110 to 120 F). This is warm enough to help preheat the material as it enters the extruder, yet cool enough to prevent bridging in the feed throat.

A good way to monitor feed-throat temperature is to install an immersion thermometer in the return line of the feed-throat cooling water. The immersion thermometer can be fitted by installing a “T” fitting in the line. Place a globe valve after the thermometer to keep the water chamber of the feed throat full and eliminate cavitation of the system

.

STICK-SLIP CONCEPT

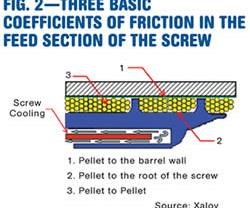

The first barrel zone that should be set is zone 1, which has the most effect on solids conveying of the resin. Three coefficients of friction (COF) take place in that zone: friction between barrel and pellet, friction between pellet and pellet, and friction between the root of the screw and pellet.

The main theory of solids conveying is that the resin must stick to the barrel and slip on the screw. So cooling the root of the screw will reduce the COF between the steel of the screw and the plastic pellets. Screw cooling should always be installed in the core of the screw in the feed section to give the operator another zone of temperature control on the extruder.

Now zone 1 can be set to a temperature that will maximize solids conveying of the resin. Zone 1 should be set approximately 10° to 25° F below the resin supplier’s suggested melt temperature—or, as mentioned earlier, 10° to 25° below the adapter and die zone settings.

For most polyolefins, zone 1 should be set between 300 and 400 F. The higher the final recommended melt temperature for the resin, the higher zone 1 can be set. It should be set as high as possible without causing bridging in the throat. With sufficient cooling in the feed-throat casing, higher temperatures can be set in zone 1.

It takes energy to melt plastic. So zone 2 should be set between 125° and 175° F higher than zone 1. This elevated zone temperature will not cause a higher melt temperature because the resin is still in pellet form at this point. But a higher temperature in this zone will put more energy into the resin and help melt the polymer.

Energy can be imparted to the resin via mechanical energy from the screw or energy from the heaters. Introducing large amounts of energy via the barrel heaters in the rear of the extruder normally will reduce the drive-motor load or amperage.

Temperatures in the remaining zones should be set in evenly declining steps between zone 2 and the final metering zone. For example, in an extruder with five zones, if there is a 60° F difference between zone 2 and zone 5, then zone 3 will be set 20° below zone 2, and zone 4 will be 20° below zone 3, leaving a final 20° drop to zone 5.

The temperature settings suggested in the accompanying figure are starting points suitable for the polyolefins mentioned—a Ziegler-Natta LLDPE, a metallocene LLDPE, and a plastomer. These barrel-zone temperatures are specifically recommended for barrier screws and will condition the resin in the least stressful manner.

Proper setting of barrel temperatures will also help reduce screw and barrel wear, which can be caused by forcing cold resin into the barrier section of the screw. For example, a flat temperature profile for PP will not reduce resin viscosity enough to pass through the barrier section. Too high viscosity then causes high barrel pressures, which accelerates screw and barrel wear.

ABOUT THE AUTHOR

Tim Womer has designed over 8000 screws for single-screw extrusion, blow molding, and injection molding in a career of more than 30 years. He’s also a past president of SPE and member of the Plastics Pioneers Association. He can be reached by e-mail at t.womer@us.xaloy.com.

Related Content

How to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

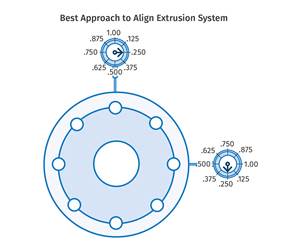

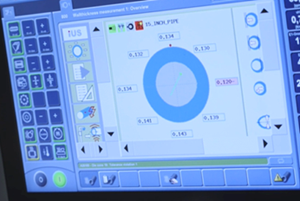

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

(2).jpg;maxWidth=300;quality=90)