October’s K 2019 show in Düsseldorf, Germany, focused heavily on the role plastics will play in the “circular economy.” Recycling is a critical component of realizing real gains in sustainability. Based on the new technology showcased at the giant triennial trade show, builders of recycling machinery are ready to answer the call.

Here are some of the latest developments displayed during the weeklong trade show not previously reported (check out September’s Keeping Up section of the September issue for more news on recycling and scrap-reclaim equipment at K 2019 from Amut, Erema, Gamma Meccanica, Herbold, Lindner, Tomra, and Weima):

Next Generation Recycling Machines (NGR) presented its new NXT:Gran series at K 2019. The company announced that this series will replace its S:Gran series (shredder-feeder-extruder combination) for processing plastic waste. The new design is said to give up to 40% higher throughput rate, simplified control and operation, and updated safety feaures.

NGR says the NXT:Gran model builds on the S:Gran ability to repelletize internal scrap for reuse in the primary production process. Also improved is overall maintenance accessibility. NXT:Gran still features the Start-Stop function, which readies the system for operation in only a few minutes and does not require any supervision when stopping.

At the NGR booth, visitors also could scope out NGR’s Liquid State Polycondensation (LSP) technology. Using a gamepad, attendees were able to take a virtual walk through NGR’s PET Test Center in Austria to experience the PET recycling process.

NGR also announced that its C:Gran series—a cutter-compactor-extruder combination—has been extended to machines for outputs of 4850 lb/hr and over. The system offer inline measurement of MFI, mechanical and optical properties (color, polymer defects)—and even can identify the polymer itself—to give recyclers the ability to determine melt quality in-process and to initiate appropriate sorting measures or additive feeds immediately.

Using a gamepad, attendees were able to take a virtual walk through NGR’s PET Test Center in Austria to experience the PET recycling process.

Ettlinger, a member of the Maag Group, unveiled the ERF 1000 high-performance melt filter for high throughputs in recycling of plastics, its largest model to date. Four filter drums provide a total of 6280 cm² of filtration surface—twice as much as the previous largest size, model ERF 500—to remove foreign particles from polymer feedstock containing up to 18% contaminants. Both machines share the same small footprint. ERF filters are now available in four sizes, from the ERF 200 for throughputs up to 1763 lb/hr to the new model for up to 22,046 lb/hr, depending on application.

The ERF 1000 reportedly combines high productivity with ability to meet ever stricter quality requirements. The company says it is suited to virtually any kind of material, including packaging based on LDPE, LLDPE and HDPE. The large filtration surface, along with its 60 µm (230 mesh) screen size (which is now also available for all Ettlinger filter models), enables qualities that “were previously out of reach,” the company said.

Like all Ettlinger ERF filters, the new ERF 1000 is self-cleaning and works with a rotating, perforated drum, through which melt continuously flows from the outside to the inside. A new feature is that the ERF 1000’s four filter drums can be individually replaced without disrupting production.

Sorting Technology Advances

STF Group of Germany launched two new products, the STF self-cleaning friction cleaner and the star screen. Both can be retrofitted to existing sorting and washing lines. The new self-cleaning friction washer features a counter-rotating screen basket. Reported advantages include the self-cleaning function and reduction of fines, which reportedly provides recyclers with a better yield and less screen wear, resulting in longer screen life.

The New STF star screen deck is a modular design of seven rotary shafts per module. These modules can be combined and extended, depending on the amount of material to be treated (tons/hr). The main application of star screening is to separate bottles and already loose labels efficiently after the label scraper. An additional air-suction and air-vacuum system can be added to the deck to increase separation efficiency. The company says the new design is more maintenance friendly; the shafts can be removed with two bolts per side.

Tomra Sorting Recycling extended its line of high-precision flake-sorting offerings with the new Innosort Flake sensor-based system that combines color and material sorting, reliably removing PVC, metals and opaque flakes. The company touts it as an all-in-one PET sorting solution for plastic recovery facilities, which ensures constant and high-quality output as well as a high throughput.

The PET flake dual-sensor sorting solution is equipped with the unique combination of RGB cameras and ultra-high resolution NIR sensors to sort plastic particles from 2 to 12 mm by color and simultaneously by polymer types.

Innosort Flake also features Tomra’s patented Flying Beam technology. High-speed, high-precision NIR sensors enable 2-mm polymer recognition, which is said to significantly reduce loss of valuable PET flake material, with final losses averaging below 2%. The sensor detects the a broad range of polymers, so that contaminants such as PVC, PE, PP, nylon, and POM (acetal) are eliminated, resulting in higher-quality yields.

New sensor-based system combines color and material sorting, reliably removing PVC, metals and opaque flakes.

Sesotec GmbH showcased metal detectors from its GF, Protector and Rapid Pro Sense 6 series at K 2019. The detectors can be used in a variety of material infeed applications and ensure high plant availability for processing machinery and equipment by preventing unscheduled machine downtime due to metal particles and avoid the repair costs associated with breaks in production and potential recalls.

The Rapid Pro Sense 6 metal detector, which was unveiled at K 2019, has a newly-developed reject mechanism designed for compound manufacturers that have frequent color changes or process abrasive materials.

New Innovations in Granulators

At K 2019, Hellweg Maschinenbau of Germany showcased its granulators with its new digital Smart Control system. This enables networked communication of the machines with upstream and downstream components, as well as with operators, in line with Industry 4.0 principles. The new system measures and stores power consumption as well as (for example) rotational speed and bearing temperatures and monitors the service life of bearings, blades, screens and the wedge-profile drive belts (V-belts). This new Smart Control system is available for all Hellweg granulators from the 150 series upwards.

The new “boost operation” option enables a short-term increase in grinding performance, in order to compensate for production-related fluctuations. In addition, speed ranges have been defined for various plastics, thanks to which, for example, low melt-temperature granulation can be performed continuously without problems, so that water-cooling is not required.

Rapid Granulator unveiled what it calls “the biggest innovation in low-speed granulation in years.” The new OneCut Pro gives injection molders the flexibility to adjust the speed range when granulating at low speeds—from the standard 25 rpm to a range of 15-35 rpm.

Running the new machine at the low end of the speed range helps improve the quality of reground highly brittle materials by minimizing dust generation, Rapid says. Reducing rotation speeds from 25 rpm to 15 rpm also reduces noise levels as much as by 3-5 dBa. Meanwhile, the ability to run the machine at higher speeds allows molders to increase capacity by 30-40%. The torque level is maintained regardless of speed, states Rapid.

Additional benefits of the new machine include the operator-friendly “Open Hearted” design. The OneCut Pro also uses a new system that reportedly can cut energy usage by 80%. Operators can stop the machine when accumulating materials, rather than having it run continuously.

Related Content

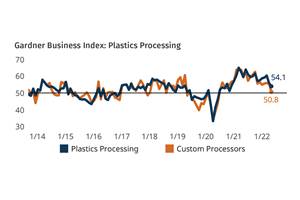

Plastics Processing Growth Slows Slightly

May reading for plastics processors is, for the most part, a continuation of what we saw in April.

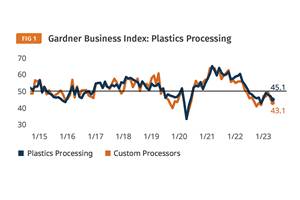

Read MorePlastics Processing Contraction Continues

Contraction dominated the GBI index for overall plastics processing activity and almost all components, collectively suggesting a slowdown.

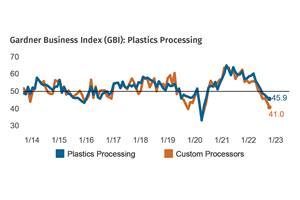

Read MorePlastics Processing Contracts Again

October’s reading marks four straight months of contraction.

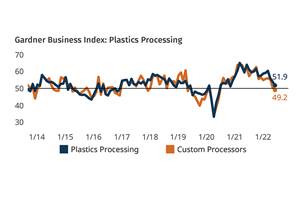

Read MoreProcessing Slips as Summer Simmers

Monthly index suggests slower growth in June for plastics processors overall and contraction for custom firms.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More