Think Your Molding Operation Is Productive? Find Out How You Stack Up Against Others

Participate in Plastics Technology’s ”Top Shops” benchmarking survey and gain access to a free customized report measuring your key metrics against the cream of the crop.

These days, most molders have metrics they use of measure their operation’s efficiency. Whether it’s done his manually or with software, molders are almost always keeping track of a slew of parameters that they use to determine just how productive they are, looking at matters like uptime, mold-change time, and the like. All well and good, but how do you know if your operation is truly best in class unless you have some sense of how good “the other guys” are? You may have a “best practices” standard against which you measure yourself, but what if it falls short against your competition?

Plastics Technology is endeavoring to help you answer that question with its Top Shops Program, which has evolved from the former World Class Processors benchmarking study. Unlike its predecessor, Top Shops focuses specifically on injection molding. It’s a comprehensive online survey (survey.ptonline.com/topshops) that, when completed, will let you see just how you stack up across multiple metrics versus other injection molding facilities. All survey data are kept 100% confidential.

By now, you may have already received an email from us pointing you to the survey. Or perhaps you’ve seen reference to it in on our website, in one of our Blogs, or on one of our social media sites. But if you haven’t filled out the survey yet, there is still time. Yes, time is becoming a more precious and valuable commodity each day. But there is also value ($500, according to our calculations) in a customized report for every company that fills out the survey that will show you how the key metrics you track—machine utilization, on-time delivery, scrap rate, mold-change time and more—compare to the molders you compete with for business.

Maybe your facility’s performance rises to the top. Maybe not. Regardless, you will find lots of actionable value in knowing how your facility stacks up. Discover relative strengths so you can keep things humming, and relative opportunities so you can address them. You can even get the data sliced and diced the ways you want or sign up our consultants for help in getting the most out of it. Participants in Top Shops programs say the benefits of benchmarking range from reducing costs to increasing sales.

This October, we’ll be reporting on the results of the survey, as well as highlighting molders that ranked best in class. Smart molders that get honored as a Top Shop may also figure out ways to make hay out of that acknowledgement from a marketing standpoint. How about sending a press release to your customers, doing a little chest thumping? What about putting that Top Shops logo on your website and social media outlets. While Top Shops is a relatively new benchmarking study for Plastics Technology, for years it has been a research staple of our sister publications such as Modern Machine Shop and Products Finishing. The accompanying photo shows what a Products Finishing honoree thought about the designation. Pretty clever, I think.

Programs like Top Shops would not be possible without the investment made in research by our parent company, Gardner Business Media (GBM). GBM has established a separate division, Gardner Intelligence, that daily conducts research vital to manufacturing. Some of that work is reflected each month in this magazine with our Plastics Processing Index and Market Watch columns. Gardner Intelligence also offers proprietary research to processors and across the supply chain, and can collaborate directly with you to develop programs that reveal insights on technology, operations, advertising and competition.

Related Content

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

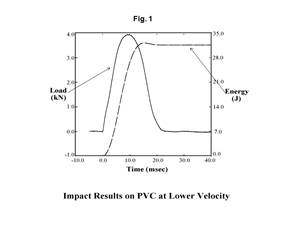

Read MoreThe Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More