Like many good ideas, NyproMold’s virtual mold-qualification process was a little ahead of its time. A few years back, Rob Irwin, director of new business development and the team and NyproMold’s Tech Center started mapping out what a virtual mold qualification would look like, even trialing the process with select customers, for the Clinton, Mass.-based maker of precision injection molds.

Remote qualifications could not only save clients from the hassle, time and money spent to fly to Massachusetts, while also allowing disparate geographic locations the ability to simultaneously see the mold run, but also provide tangible video documentation of how the tool should work for molders, versus them trying to remember what they saw in Clinton. Win-win-win, right?

“It was almost a full year after we put it on the shelf that COVID hit, and it was like, ‘Let’s dust this off; we’re going to have to use it.’”

“We looked at what the process would provide and thought, ‘From a time and cost standpoint this is really valuable to molders,’’’ Irwin remembers. “So we put it out, and the feedback was almost overwhelming along the lines of, ‘Yeah, that sounds really cool, but no thank you.’”

First shots from a new tool are measured in Nypro’s virtual mold-qualification program.

At the time, Irwin said people who said “thanks, but no thanks” to virtual visits could largely be divided into two camps: 1) molders who felt the import of assuring a functioning tool prior to delivery required in-person inspection, and 2) molders who saw inherent value and a relationship-building opportunity in face-to-face meetings.

Irwin explains, “People told us, ‘My key job is to make sure that the molding process here goes off without a hitch, and if my name’s got to go on that tool, I’m not going to run the risk of it not working out and have my boss ask, “Why couldn’t you have taken two days to go up and see it run before it was shipped down here?”’”

NyproMold read the room, and the program was mothballed. Then coronavirus arrived. “It was almost a full year after we put it on the shelf that COVID hit,” Irwin says, “and it was like, ‘Let’s dust this off; we’re going to have to use it.’”

Trust the Process

For NyproMold, the qualification plan, virtual or in person, starts taking shape as the mold design is finalized. NyproMold determines the test criteria that a molder or brand owner will require to sign off that the mold is valid and will pass testing when it ships. That, and many other aspects of the process, are the same with virtual mold qualifications, but there are some key differences above and beyond not booking a flight and hotel.

With the new process, two to four weeks prior to mold completion, Irwin says the plan is reexamined and “tidied up” with test-room time put on the calendar. At this point, the company also gives the customer a preliminary explanation of the virtual mold-qualification process. Irwin says that conversation is designed to set the expectations with the customer and make sure all the “right players” are engaged. Once a clear team is established, it’s determined who’s going to review parts and do part inspection, as well as how and when they’ll do that. Video connections and links are sent and tested.

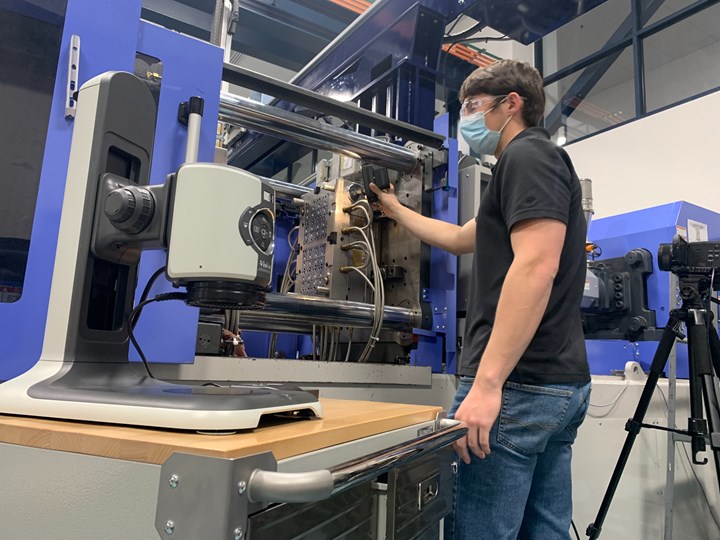

NyproMold brought the same rigor and attention to detail to creating the virtual mold-qualification process that it brings to the process itself, and continued learning as it went. The company tested multiple cameras and different streaming platforms before settling on its current setup. It was quickly determined that the camera speed and resolution, as well as the stream’s resolution and broadband requirements, precluded using a Microsoft Teams or Zoom-type platform. Instead, specialized video links and a higher-end streaming service was required.

“Once they see the ease of use they say, ‘There’s a good number of instances where this is probably the easier way to do it.’ It’s forever going to change habits.”

NyproMold also figured out that there would have to be a headcount limit. Once connections numbered more than four or five, quality deteriorated. “This wasn’t something where we said, ‘Hey, just pass around this link to 25 of your guys and everybody hops on,’” Irwin says. Minimizing lag time between the actual molding and the streaming of the molding was key. Given the fast-cycling tools NyproMold makes, more than 3 sec lag would make it difficult for attendees to be sure they were talking about the same molding cycle.

NyproMold also got better at scheduling the qualifications, learning that giving a specific meeting time but making attendees wait for a mold to come to temp or resin to dry wasn’t a great experience. As it would be for an in-person visit, time with the tool without customers was valuable. “We wouldn’t tell a customer on a brand-new mold design that we hadn’t made before, ‘Hey, this mold’s going to be ready on Wednesday night, why don’t you come Thursday morning,’” Irwin says.

The calls also became a mix of live feeds of the mold and prerecorded videos, letting customers view the tool at their leisure. Included in the prerecorded material are videos of mold setup in the machine and teardown on the bench. Customers found these valuable once the mold was in their shop and they had to install it on a machine or perform preventative maintenance on it. As part of the teardown videos, NyproMold would take video of critical shutoff surfaces, allowing the customer to see their condition as new.

With the live feed, Nypromold was also able to modify a process, run another few cycles and show it on camera again. Per customer request, it could also zoom in on parts to show parting lines or gate vestiges, or provide a closer image of a specific cavity in the mold.

Shifting Online

While the reception of its initial rollout was tepid, virtual mold qualification’s performance during the pandemic may give it a future even after the pandemic subsides. “This situation is analogous to the idea of a person who, pre-COVID-19, was a conventional, big-box store shopper that enjoyed going out and picking things up, seeing things, and never would have used online shopping,” Irwin says. “Now they’re exposed to it, and once they see the ease of use they say, ‘There’s a good number of instances where this is probably the easier way to do it.’ It’s forever going to change habits.”

High-resolution cameras used in NyproMold’s virtual mold-qualification process allows molders to see how parts eject from their new tool, among other functions.

Related Content

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreRead Next

Smart Tool, Electric Tool

The old gray mold ain’t what she used to be. Or won’t be for long, if recent trends hold up.

Read MoreMill-and-mail moldmaking no more

“The days of just putting a mold on the shipping dock and hoping the customer comes and pats you on the back are long over.”

Read MoreMoldmaker Branches Out With New Services & Technologies

NyproMold offers new development tooling program and the latest in servo drives, enhanced cooling, and CT scanning.

Read More

(2).jpg;maxWidth=300;quality=90)