Circular Manufacturing Helps Startup Produce Sunglasses from Recycled Material

Yuma Labs has created a closed-loop model for its sunglasses line.

Yuma Labs sunglasses are made from recycled materials, including ocean plastics. Photo Credit: Yuma Labs.

Belgian sustainable sunglass maker Yuma Labs is truly focused on a circular economy as the company’s specs are made from plastic reclaimed from the ocean—old bottles and nets, specifically.

Yuma Labs Sebastiaan De Neubourg founded the company in 2016 after he left his previous job as a consultant specializing in the circular economy.

“I was doing a lot of workshops with companies, startups, and entities on how to implement circularity into their business models,” he said. “We developed many great ideas, but they only lived in Post It notes and weren’t implemented.”

De Neubourg said the friction occurred because it is not easy for companies to change their business structures and processes towards a circular economy.

“So, I figured that starting a company where I could illustrate the circular economy myself via creating a tangible, easy-to-understand product, and process – in this case, sunglasses,” he said. “When I say ‘circular economy’ for Yuma Labs, I take it very literally. We want to make sure that all the plastics with which we make our glasses are not only made from recycled materials but are recyclable at end-of-life.”

Yuma Labs initially started developing its own complete in-house process via 3D printing in 2016, and in 2017, started its first successful Kickstarter campaign through which they sold their first collection.

After the crowdfunding campaign, Yuma Labs shifted its business model to B2B from B2C.

“We have our label, Yuma Labs, but most of our revenue comes from B2B activities,” he said. “We design, produce, ship, and recycle a collection of sunglasses, either white-labeled or collaborating with existing fashion brands to turn their existing business into a more circular one.”

Materials

In addition to ocean plastics, the company also uses recycled PET from post-consumer bottles.

The biggest challenge when working with recycled materials is the consistency of the material, De Neubourg said. “The quality of a single batch, and through various batches throughout a production line, needs to be very consistent; otherwise, you get fluctuations in the quality of the product, which has given us a lot of headaches,” he said.

Yuma Labs now uses recycled PET from Denmark, Germany, and the Netherlands because they have a thorough waste sorting process and clean materials and work with recycled PET from post-consumer bottles. The recycled fishing nets are from the south of Europe, recycled acrylic that originates from Italy, and the company works with specific partners specializing in these kinds of recycled plastics. De Neubourg said they prefer working with larger players that can provide the material quality they need. They’re also working on expanding the types of materials they use.

“We always use pure, single-material plastics. Mixed plastics become challenging to recycle at end-of-life,” he said. “Therefore, we diligently ensure that the plastic we use throughout the lifecycle of the glasses is as pure as possible.”

When customers wear out a pair—or the next fashion cycle demands an eyewear upgrade—a bar-coded return label inside the product package lets them slip the sustainable sunglasses into the nearest mail slot. For Yuma Labs, it means a continuous supply of raw material and a chance to stay engaged with customers and boost loyalty.

While Yuma Labs originally used its own 3D printers to produce the recycled sunglasses, it proved too much for a single company, so they moved to an outsourced production entirely. They now work with China, Vietnam, and Italy to produce the sunglasses, which are either 3D printed via SLS, multi-jet fusion 3D printing or injection molding. In addition, Yuma Labs is using Autodesk’s Fusion 360 CAD software for 3D modeling.

“3D modeling via Fusion 360 also helps ensure that the sunglasses we produce can also easily be disassembled,” De Neubourg said. “We can easily simulate this within Fusion, an essential feature when discussing a circular economy.”

Related Content

Gerdau Graphene Launches “First” Graphene-Enhanced PE Additive Masterbatch for Extruded Packaging and More

The company has also partnered with conglomerate Sumitomo Corp. for distribution of its graphene-enhanced masterbatches in Japan.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

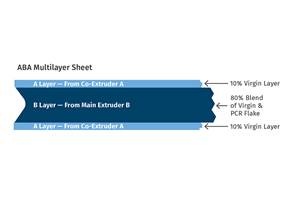

Read MoreThermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreFungi Makes Meal of Polypropylene

University of Sydney researchers identify two strains of fungi that can biodegrade hard to recycle plastics like PP.

Read MoreRead Next

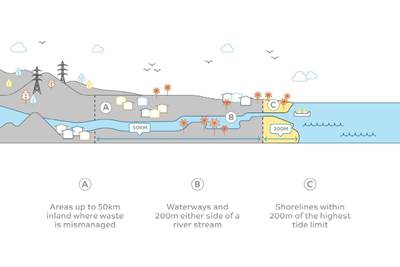

SABIC Develops New Polymers from Recovered Ocean-Bound Plastics

Resin giant partnering with Malaysia-based plastic recycling company HHI on this initiative.

Read MoreClothing Hangers Made from Ocean-Bound Plastics

New hanger made from 100% recycled plastic that is gathered from the ocean or intercepted before entering the ocean.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

(2).jpg;maxWidth=300;quality=90)