Inline extrusion and thermoforming – as in this OMV line – offers advantages in thorough and consistent heating of the sheet from the surface to the core, and some pre-expansion will already have occured. (All images: OMV Technologies)

Current legislation across Europe and proposed legislation in the U.S. and other parts of the world is causing concern for thermoformers who are worried about both the inconsistent availability of post-consumer recycled (PCR) resin as well as its associated costs and quality. In the U.S., proposals include imposing taxes on single-use plastics and mandating at least 25% PCR content by 2025 and 30% by 2030. Also, there are attempts by the California Dept. of Resources Recycling and Recovery (CalRecycle) to implement the California Assembly bill AB 2784, which requires that the PCR used in thermoformed containers be derived specifically from recycled thermoformed containers.

Since the introduction of these legislative proposals, OMV Technologies, for one, has been actively involved in assisting thermoforming companies that are making the transition into the use of PCR. An area of particular involvement has been with companies focused on so-called “circular” recycling. Simply put, circular recycling is when PCR from a thermoformed product is used directly to manufacture new thermoformed parts. If the intent is to manufacture parts for food packaging, the PCR being used will have to meet the FDA’s requirements for food-contact applications.

There are a wide range of factors to consider from both the thermoforming and the extrusion sides. For example, the final quality and functionality of the thermoformed parts starts with consistent quality sheet and, in the case of hygroscopic materials such as PET, proper crystallization and drying of the PCR flake before sheet extrusion is of paramount importance.

What follows is my recommended best line of attack in order to enable the PCR to go through the thermoforming process efficiently, starting at the extruded sheet:

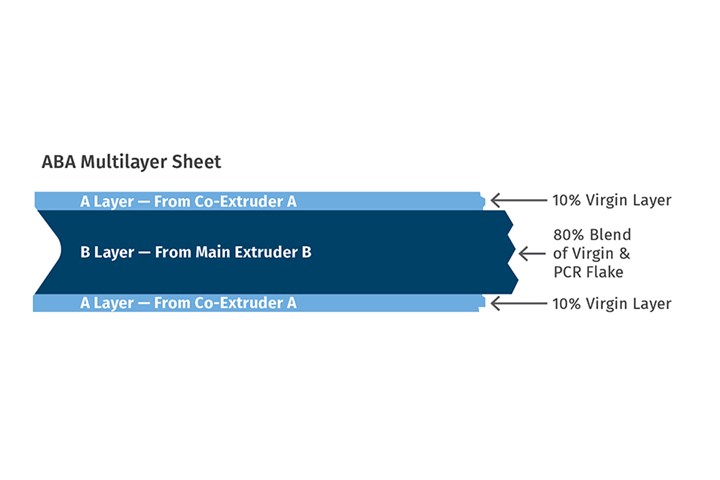

FIG 1 An ABA multilayer sheet structure allows the ability to change the thickness of each layer for cost and final part performance.

Extruded Sheet with PCR Content

Whether you opt to utilize roll stock or to extrude in-line, a choice has to be made whether to run a monolayer or a multilayer sheet. This is not to be confused with the term “Mono Resin” sheet, as the multilayer sheet in this case consists of the same base resin, but with the benefit of running a sheet with a layered structure usually consisting of the regrind (PCR) content in a middle layer, capped with virgin outer layers. This is typically referred to as an ABA structure.

Whether you are forming sheet from roll stock or using an inline extruder, it is essential that the sheet be heated to the core.

Using a multilayer sheet has many benefits, starting with the fact that only the outer layers are in contact with the food. The thickness of each layer can be adjusted individually and the layer structure can also easily be reduced to an AB structure where the virgin resin is only on one side of the sheet, depending on the application. Having the ability to change the thickness of each layer has many cost and final part benefits, which is why one should always err towards a multilayer sheet structure. For example, cost benefits can be achieved if you are adding a stabilizer to boost the PCR’s properties in the center “B” layer and not the cap layers. Similarly, if you require an antifog additive, it would only have to be added to the outer layer or layers. There are numerous thermoforming configurations available to us today and most can be run either by extruding directly inline or offline (roll stock) thermoforming.

▪ Inline thermoforming: This method offers the benefit of controlling your industrial regrind (also referred to as post-industrial recycle – PIR – content) because the skeletal waste from the sheet is directed straight to a grinder along with rejected parts and then channeled directly back to a day bin where it is conditioned to be reused in the extrusion process at preset percentages. PCR flake can then be introduced as needed at the conditioning/blending station. Maintaining the IV (intrinsic viscosity) or the MFI (melt flow index) of the resin and regrind flake is absolutely critical in order to maintain consistent quality sheet.

The greatest benefit of inline thermoforming is that the sheet entering the thermoformer’s pin chains is already heated to the core (center containing the PCR) and all that is needed is to heat the outer layers as needed. See more discussion on this below.

▪ Offline (roll stock) thermoforming: When roll stock is utilized, the process is very often not continuous because of the time it takes for roll changes. Very few companies master roll changing without interrupting the forming process. This, along with the fact that the sheet has to be reheated from the ambient temperature of the production facility to its forming temperature, can easily lend itself to inconsistent and problematic parts.

Whether you are forming PET, rPET, HDPE or HIPS sheet from roll stock or an inline extruder, it is essential that the sheet be heated to the core. If the core remains cold and only the outer layers of the sheet are brought to the correct forming temperature, the most likely result will be warped parts along with poor impact properties. Heating the sheet to the core from roll stock requires a lot more energy than when the core is still hot coming out of inline extrusion. Regardless of PCR usage, properly saturating the sheet with heat is always a concern, and this can be exacerbated when adding regrind flake from another source.

When utilizing PCR regrind flake, depending on the reliability of your source, it is likely that you will have broader fluctuations in the IV and/or MFI, which will adversely affect the hot strength of your sheet (sheet sag) and final quality of the thermoformed parts. Being able to better control the temperature of the core and outer sheet layers prior to forming will help to ensure consistent quality parts from cycle to cycle and run to run.

Adding a conduction or convection type preheater can help to reduce the risk of overheating the outer layers of the sheet in order to get the heat into the core of the roll stock. In the case of PET, overheating the surfaces of the sheet can result in premature crystallization (whitening of the sheet and loss of clarity) and could negatively impact the ability to form the sheet. Being able to preheat the sheet to at least 200°F will also, in the case of brittle materials, have many benefits at the infeed of the former. Edge preheaters will not be needed and some pre-expansion of the sheet will have already have occurred (simplifying pin-chain setup), especially with semi-crystalline materials like PP.

When utilizing PCR regrind flake, it is likely that you will have broader fluctuations in the IV or MFI, which will adversely affect the hot strength of your sheet (sheet sag) and final quality of the thermoformed parts.

Heating the Sheet

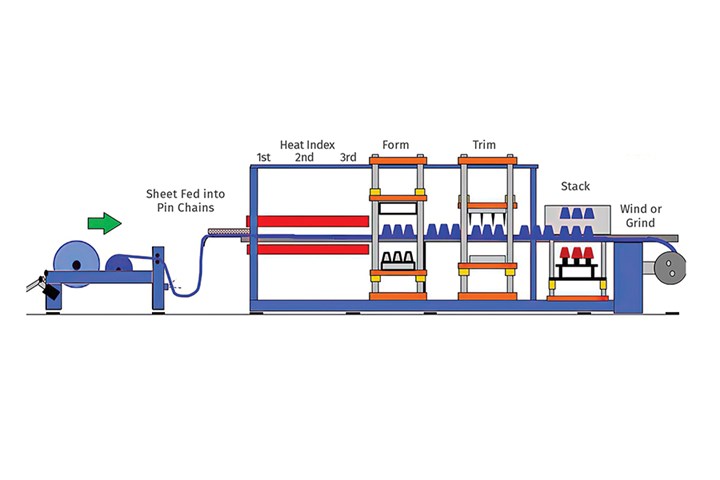

Depending on the type and configuration of your thermoformer, you should have at least three heat soaks in the oven before the sheet reaches the form ing station. Longer ovens are always preferred for semi-crystalline materials like PP and HDPE, and for thicker sheet, to increase the number of indexes in the oven. Inline extrusion or at least a preheater will help with heating the sheet to the core, as mentioned before.

There’s definitely an advantage to heating and forming a multilayer sheet structure, since utilizing a cap layer with a resin that has a lower MFI than the PCR in the center layer will enable you to control the sheet sag and thus utilize higher percentages of PCR. In some cases, this may require thicker cap layers.

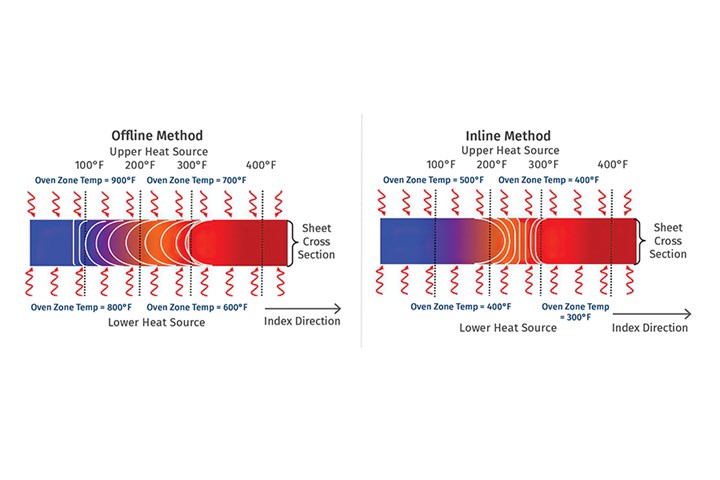

As illustrated in Fig. 3, it would be easier to bring the core of the sheet to its thermoforming temperature with the inline extrusion method than that of the offline method. This would then allow the operator to reduce the temperature on the last heat zones before the forming station to create a colder sheet surface. This can in some cases create biaxial stretching when the sheet surface is formed at a colder temperature (solid-state forming). This in turn creates a part with a higher topload and hoop strength. It also creates better clarity in the case of clear parts. This is very difficult to achieve when utilizing roll stock.

FIG 3 A comparison of offline (roll stock) and inline thermoforming methods.

Forming and Trimming

You can form a part on any thermoformer, but can you manufacture those parts efficiently and with consistent quality? Without going into the many machinery configurations available, as well as the various advanced forming methods, choosing the right thermoforming platform for a particular part and designing the tooling to incorporate the latest forming techniques will allow you to manufacture consistent quality parts with the highest efficiencies (>90% OEE).

The biggest mistake made in thermoforming today is the wrong choice of machinery platform for a specific product geometry. Now, with the mandates for high percentages of PCR, many who are not diligent and careful in these decisions will feel the pinch. Utilizing the wrong platform or older, poorly maintained machinery will result in having to increase the sheet thickness to ride through the form and trim issues, resulting in heavier parts and loss of profit – and perhaps ultimately losing the business to a competitor. The following guidelines are recommended for all continuous forming regardless of the recycle content. If these requirements are met, it will narrow the margin of error for forming sheet with high PCR content.

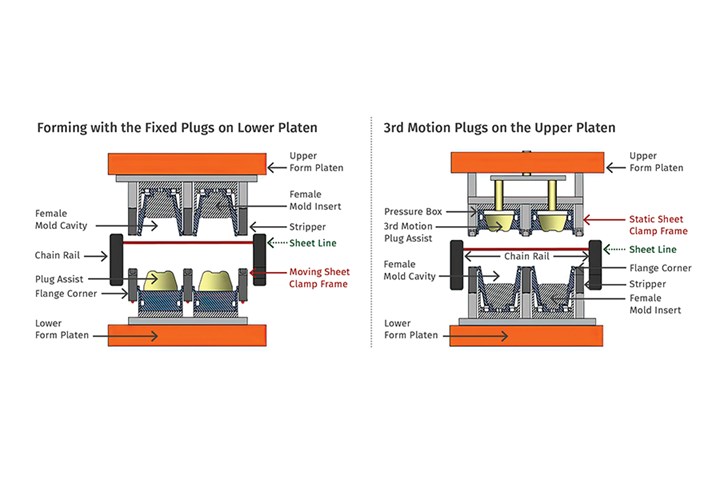

▪ Fixed plug or 3rd-motion plug assists: When using fixed plugs, the speed of the plugging action depends on the platen speed, and the depth of the plug cannot be easily changed. Both platens cannot be closed at the same time and thus reduces cycle time.

Servo-driven 3rd-motion plug assist opens up the forming window and allows for immediate changes to plug speed, depth and timing from the operator control screen. This is essential for consistent-quality parts with consistent wall-thickness distribution.

▪ Consistent vacuum: Use 25 in. Hg and a vacuum reservoir volume three times the total volume of the mold cavities.

▪ High forming air pressure: At least 5 bar (72 psi) is required for the forming air pressure and 110 psi is optimal. This will allow for solid-phase forming of the sheet, which will help to create biaxial orientation as the sheet is driven down by the plug assist and then stretched by the forming air up against the mold cavities.

▪ Mold-temperature control units: Use separate mold-temperature control units (TCUs) for each tooling zone, and each zone must be capable of both heating and cooling. There must not be more than a 4°F delta from setpoint. Also needed is a high enough fluid pressure and volume to create turbulent flow (Reynolds number of 4000). Rule of thumb: a ½-in. hose ID should yield flow of at least 10 gal/min to achieve turbulent flow; a 3/4-in. hose ID should have at least 15 gal/min. Tables are available for turbulent flow rates in different hose sizes. You can establish the flow rate for your tool with a digital flowmeter or with a simple experiment: Uncouple the hose leaving the mold and place it in a bucket. Then set a 1-min timer and measure how much water you get.

FIG 4 Fixed plug on lower platen versus servo-driven third-motion plug assist on upper platen. The latter opens up the forming window and allows for immediate changes to plug speed, depth and timing from the operator control screen.

Three Continuous Thermoforming Categories

One category involves forming and then inline trimming with knife-like tools (steel-rule, forged and machined knives). The parts are formed and then indexed to the inline trim station where they are trimmed out of the sheet, leaving small tabs to carry the parts to the inline stacker.

The second category involves forming and then offline trimming with punch-and-die (matched-metal trim) tooling. The parts are formed and then the sheet leaves the pin chains and is fed into an offline trim press with a matched-metal punch-and-die. This format is beneficial for high-volume production.

The third category is form and trim-in-place, using knives or punch-and-die tooling. The parts are formed and trimmed in the same station and therefore the trim concentricity is 100%. This is an especially effcient platform for semi-crystalline materials like HDPEand PP that have a high shrinkage.

The trim-in-place method has the highest probability of success when using PCR. This is because of the fact that the IV or MFI of the flake will most likely have some variances, and these variances will have a direct effect on the shrinkage of the sheet and the final parts. When the parts are trimmed outside of the form station, as is the case with the form and then inline trim method (sheet still in pin chains), the changes in the centerlines caused by shrinking of the sheet as it cools make it difficult to keep the trimming knives aligned, especially at the outside rows. This is exacerbated by the use of the offline post-trim method because the trim station is situated substantially further away from the form station and thus subject to changes in the ambient air conditions such as drafts.

Although the requirements for thermoforming parts with and without PCR content are basically the same, unless your source of PCR is very consistent and the material properties are very stable, non-compliance with the recommendations made here will result in higher waste factors and low-quality parts. Thus, it is of utmost importance that all incoming PCR flake, pellet or masterbatch is tested for consistency from batch to batch and that the same virgin/PCR blend ratio is maintained. Conditioning of rPET resin and flake (such as drying to at least 55 ppm moisture) before extruding and the use of the correct extrusion equipment are essential to ensure good-quality sheet for the thermoforming process.

Whenever a change is made to the blend, a strict product qualification needs to be completed, starting with the extruded sheet through the thermoforming process and the final testing of the finished product prior to signing off on the final parts.

ABOUT THE AUTHOR: Mark Strachan is the co-owner and CEO of OMV Machinery based in Verona, Italy, and Royal Palm Beach, Fla. He started his career in the packaging industry in 1982 as an electronics engineer apprentice for a large, South African thermoformer of food packaging, and then started his own thermoforming business, PacMark, CC, which became one of the largest suppliers of plastic cups and trays for airline catering. Strachan later sold his business and moved to Germany, where he held engineering and production-management positions at large plastics packaging manufacturing firms in Europe and the UK. His hands-on experience in both thermoforming and extrusion led to opportunities in the U.S., where he worked with several machinery OEMs such as Sencorp and Commodore Machine Co. Strachan offers thermoforming seminars, in- house training for thin gauge forming, and consulting services in product design to final commercialization, as well as assistance with intellectual property protection. Contact: (754) 224-7513; mark.strachan@omvtechnologies.com.

Related Content

Ingenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)