Meeting the Social Challenges of Changing an Industry

At K 2022, Milliken highlighted its various sustainability collaborations in addition to technological achievements.

A cornucopia of technological innovations was on display at the recent K Show in Germany, from a three-story polycondensation plant to a hand crank-powered injection molding machine. But adapting the plastic industry to meet contemporary challenges requires social innovation as well as technological.

Many of the collaborations described at K included the Milliken company. “We are more than just additives. We make both technical solutions and partnerships for better business,” said Diedre Sandrock, director of sustainability and innovation at Milliken.

Sustainability is not a new concept at Milliken: as Sandrock pointed out, the company’s first recycling policy was drafted in 1901. When Halsey Cook became CEO in 2018, he revised Milliken’s mission statement to emphasize sustainability and cooperation: “Together, we strive to positively impact the world around us for generations to come.”

So, beyond sounding nice, how does the focus of this statement differentiate, in other words what concrete steps could we expect to see from a company that makes such a claim? Milliken representatives spent much of the week offering various answers to this question.

A new, more responsible management system for plastics requires social infrastructure at all points in the value stream. The need might be most evident at the collection phase. Consumers are faced with a collection system whose rules vary wildly from one locality to another, and many are skeptical of recycling due to the societal backlash over plastic waste.

“Oregon and California are trying to standardize collection, this needs to happen in each state and country,” said Scott Trenor, principal scientist at Milliken. The Plastics Pact has called for the elimination of “problematic materials”. Trenor said these can include materials that are completely recyclable, such as polystyrene, but are problematic for other reasons such as low yield and sorting difficulty.

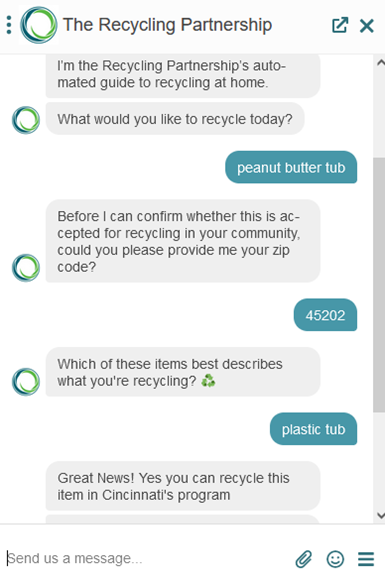

With the recycling partnership chat box, anyone can find out what items are accepted by their local recovery facility.

In the meantime, a chat bot offered by The Recycling Partnership, of which Milliken is a funding member, helps consumers determine what is recyclable in their community.

Another effort to use information to improve recycling is the HolyGrail 2.0 initiative, driven by the Alliance to End Plastic Waste and aimed at demonstrating the feasibility of covering packaging with digital watermarks. The watermarks are imperceptible to human eyes but allow automatic scanning systems to know the exact material of each package.

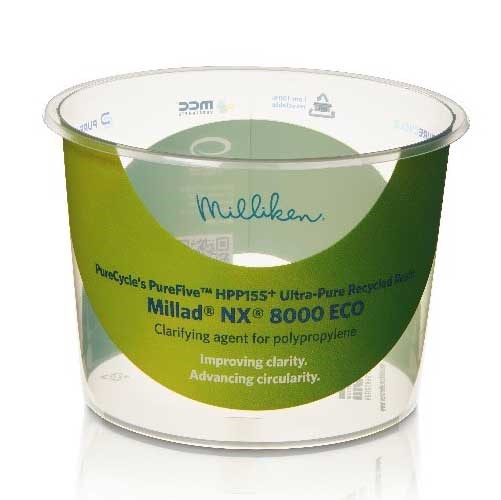

At a joint press conference, Milliken and Purecycle offered updates on their collaboration. Purecycle has a low-heat, catalyst-free process for washing additives and contaminants away from PP to prepare it for reprocessing. Milliken announced that it will be marketing a complementary PP concentrate based on recycled resin carrier. “If you put an additive package into a fully recycled product, you’re always gonna have 3% that comes from fossil-based PP,” explained Purecycle CEO Dustin Olson. “But with this solution, because our product is 100% recycled, all of the sudden we can close the chain on full circularity.”

PP container made with Millad NX 8000 ECO clarifying agent.

Photo Credit: Milliken

Milliken additives can give materials properties that facilitate recycling, enabling cleaner streams with better processability and toughness. An example is the clear plastic container used by Ferrero Rocher chocolates. The company has a brand ambition to be 100% recyclable, biodegradable or reusable. This meant moving away from PS, but the company was reluctant to change the appearance of their widely recognizable product. Using Milliken’s PP clarifying Millad additive, they were able to switch to PP without changing their brand aesthetics.

Technology can ease the transition for brand owners, improve traceability and sorting, and make plastic materials themselves easier to reprocesses. But part of the circularity chain is with consumers, who must not only understand what to place in the bin, but be able to trust that materials will be handled responsibly from there.

“We in the chemical sector and plastic industry need to help inform consumers from a science-based perspective. Life cycle analysis and net zero carbon targets are a big part of that,” said Sandrock.

Related Content

New Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

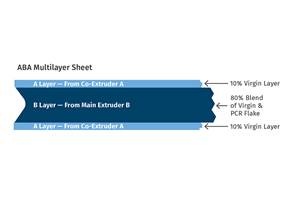

Read MoreThermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreFungi Makes Meal of Polypropylene

University of Sydney researchers identify two strains of fungi that can biodegrade hard to recycle plastics like PP.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

(2).jpg;maxWidth=300;quality=90)