Plastic Heat Sinks for LEDs “Shine” for Two Lighting Component Manufacturers

PolyOne’s Therma-Tech compounds prove their mettle replacing aluminum as an LED heat sink.

PolyOne’s Therma-Tech compounds prove their mettle replacing aluminum as an LED heat sink.

Here’s my second of a three-part installment to PT’s blog on interesting information that did not get into our upcoming June cover story: New Materials Shine Bright in Growing LED Market (read the first part on LED opportunities in automotive and street lighting). PolyOne, Cleveland, Ohio gets the space here with a focus on two case studies where its Therma-Tech thermally conductive formulations, which utilize proprietary additives and various engineering thermoplastics, proved a smart option for two European lighting manufacturers.

Savvy plastics suppliers who are leading in the LED materials arena have been striving to replace the traditional highly-conductive die-cast aluminum heat sinks in LED luminaires. This in addition to their advancements in other key LED areas such as lenses, optics, reflectors, housings and sockets. The metal heat sinks represent a substantial part of the cost of LED luminaires. Material suppliers believe that the use of plastic heat sinks would prove beneficial for the vast majority of LED luminaires, as they can reduce assembly costs , increase design freedom and consolidate parts. In the two PolyOne case studies, this certainly proved true.

• Kruunutekniikka Oy of Finland, an injection molding contractor with expertise in lighting components, knew that it could provide manufacturers of heat-sensitive LED products with improved manufacturability and performance by producing non-metal heat sinks at scale. Company product engineers came up with specifications that called for thermal conductivity in plane from 4 to 21 W/m.K (in compliance with ASTM E1461; glow wire resistance of 850 C/0.8mm (IEC 606095-2-12); and enough dimensional stability to allow it to be overmolded directly on LED components. The next step: find the right material.

Kruunutekniikka’ design engineering team collaborated with PolyOne in looking at potential options before developing a material that combined two grades of Therma-Tech thermal management compounds, both based on high-temperature nylons. The formulation was tested and phased into production, with the Kruunutekniikka Coolics brand quickly adopting the material throughout its line of customized LED cooling systems. The material added immediate benefits including: complex designs at lower costs than metal; lighter weight; inherent corrosion resistance; adaptability for ingress protection up to IP67; high-heat resistance; compliance with UL94-V0 flammability standards; and options for either electrically conductive or insulating properties.

The overall impact of this collaboration on Kruunutekniika included: a cost saving of more than 10%. Contributing factors: the Therma-Tech formulation required 37% less material due to its lower density; and substantial savings were realized during high-volume production thanks to a switch from die casting to injection molding, as well as elimination of secondary steps needed to achieve net shape with die casting. Startup times also were reduced. The company also cited that production scrap from the injection molding process can be fully recycled as part of an in-line process, helping it to meet its sustainability goals.

• Mars Otomotiv, a Turkey-based maker of lighting for the global auto and transportation industries had built a good segment of its thriving business since 2004 around LED products. However up until a couple of years ago, they were sourcing their die-cast aluminum heat sinks from a sub-supplier, which required Mars to do secondary work, including removal of flash, drilling holes and surface treatment to prevent corrosion. Use of a supplier for the parts also led to unexpected costs and shipping delays, created logistics challenges and tied up stock and working capital.

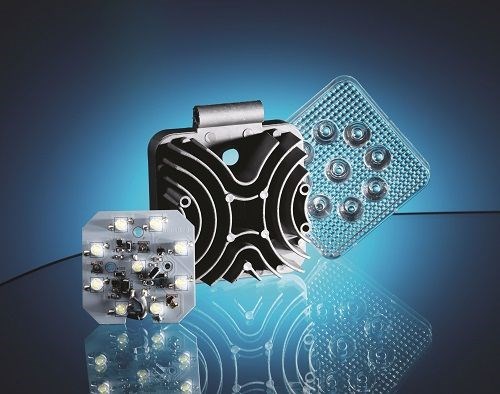

Mars engineers collaborated with PolyOne to explore non-metal options. They eventually settled on Therma-Tech TT6600-5001EC, based on nylon 66 as the best choice to provide comparable heat dissipation. Still, they faced the significant hurdle for retooling costs. Mars owned the tooling used to form the metal heat sinks, and wanted to adapt the existing mold to accommodate the new material. Working with PolyOne’s technical team, Mars engineers were able to alter the mold so it could process the thermoplastic. They completed the metal-to-plastic transition in less than four months, bringing production in-house while essentially using the same tooling.

Today, Mars Otomotiv benefits from the simplified logistics of molding heat sinks in house, including reduced order lead time, improved on-time order completion and more working capital. The thermal dissipative performance of the thermoplastic heat sink is equivalent to that of the aluminum, even the highest-power HB LED model, which provides 27 total watts in nine HB (high-brightness) LEDs. Specific gains include: 39% reduction in the weight of finished assemblies; 50% increase in the number of molded heat sinks produced each day; 20% reduction in the total cost to produce each heat sink, and elimination of secondary finishing operations.

Look for more material developments for the LED lighting sector in PT’s June issue, including PolyOne’s brand new premium light diffusing sheet UltraTuf LED (below), which can transmit between 80-90% of light while still effectively diffusing the LED points of light across the lens.

Read Part I of Lilli's LED Series—LSR for Street and Auto LED Lighting

Read Part III of Lilli's LED Series—LSRs, PPs and PCs for LED Lighting

Search for more of PolyOne’s Therma-Tech materials in PT’s materials database.

Related Content

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

(2).jpg;maxWidth=300;quality=90)