Coperion Goes Remote to Upgrade Compounding Line

Project encompassed both a control software update as well as mechanical overhauls on the system.

Coperion recently managed to upgrade a ZSK 250 high-capacity extruder at an undisclosed customer utilizing remote processes and support. In this particular project, the company worked directly with the compounder in a project that included modernizing the gearbox, mounting a new coupling, installing a ZS-EG side devolatilization unit, and updating the EpcNT control, including a rebuild of the control cabinet and monitor.

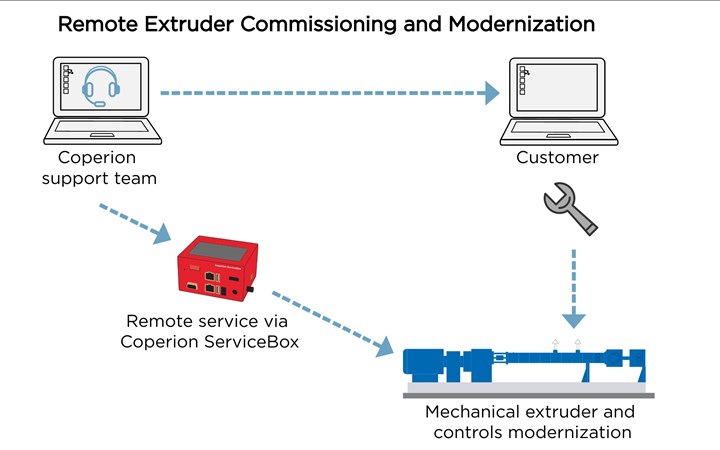

The machine builder’s three-member team based in Stuttgart, Germany did the upgrade via the Coperion ServiceBox—an integrated system for online monitoring and failure recording in extruders and compounders, as well as communication methods like video and telecommunication to complete customer requests.

Coperion has been utilizing the Coperion ServiceBox for years to perform remote software updates on its extrusion systems, but until now more complex mechanical remote tasks have been limited. This project, however, demonstrates that the technology can be used for complex maintenance and modernization projects, the company says.

Related Content

-

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

-

More Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

-

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.