Evonik Looks to Extend the Service Life of Joint Prostheses with PEEK Biomaterials

A collaboration between Evonik and Boston’s Mass. General’s Harris Orthopaedics Laboratory is underway to transfer innovation from veterinary to human medicine

Evonik is exploring the possibilities of using the high-performance polymer Vestakeep PEEK, a proven implant material for medical technology, for complex joint prosthesis systems. The specialty chemicals company is drawing on the expertise of medical specialists at the world-recognized Harris Orthopaedics Laboratory--Center for Knee and Hip Replacement at Massachusetts General Hospital in Boston. If the collaborative innovation succeeds, the service life of Vestakeep based joint prostheses could be significantly extended, consequently reducing revision surgery or years of pain therapy—transferring innovation from veterinary to human medicine.

Evonik's PEEK biomaterial is already being used successfully in the latest generation of hip prosthesis systems for pets such as dogs and cats from the Swiss company KYON. At the heart of the innovative technology is a friction partner made of Evonik's Vestakeep PEEK biomaterial with an additional carbon-fiber-reinforced PEEK ring between the ceramic head and the cup. Unpublished data indicate that linear wear is reduced by a factor of 7 with ceramic on PEEK compared to conventional pairings.

Approximately 6000 successfully performed hip replacement procedures without a single revision due to inlay wear and just as many satisfied dogs - including true champions (agility dogs) - as well as five years of careful documentation confirm the success of KYON's PEEK-based hip replacement system. Among other things, Evonik's polymer experts would like to transfer the material expertise and application understanding from veterinary applications with potential medical device manufacturers to human medicine.

Joints are complex movement systems that fulfill important anatomical functions and are constantly exposed to heavy stress. At the Medical Device Competence Center in Birmingham, Alabama, Evonik is pursuing the approach of analyzing the weak points of the joint prosthesis systems already established on the market in human medicine and developing a solution with its high-performance PEEK polymer.

Said Marc Knebel, head of Evonik’s medical systems market segment. "We are looking into the use of Vestakeep in human joint prostheses to improve the quality of life for patients. For example, we have learned to understand PEEK as a material component in complex joint prosthesis systems that can be integrated into existing technologies according to the modular principle.“

Today's joint prosthesis systems are convincing in terms of availability and reliability. However, friction partners - so-called inlays such as those between the head and the cup of a hip prosthesis anchored in the bone - are a primary weak point of current technologies. According to Evonik’s Knebel, the company’s tribological PEEK biomaterial could make the decisive difference in the future and extend the service life of a hip prosthesis fourfold.

If it were, millions of patients worldwide could do without years of pain-relieving therapies. These are often necessary to reach a certain age for surgery, so that the probability of a risky revision at an advanced age can be reduced.

Said Knebel, "The regulatory approval process in human medicine is strictly oriented towards added value for patients. We have to provide sufficient evidence of this added value to attract partners for further development steps. For this reason, we cooperate with Massachusetts General Hospital in Boston, test our material for tribological properties in their professional laboratories and receive valuable feedback that always takes us one step further."

Orhun K. Muratoglu, PhD, director of the Harris Orthopaedics Laboratory and director of the Technology Implementation Research Center (TIRC) at the Massachusetts General Hospital in Boston and Professor of Orthopedic Surgery at the Harvard Medical School noted, “At the Harris Orthopaedics Laboratory we used our state-of-the art in-vitro wear testing machines to evaluate the performance of medical grade PEEK formulations for orthopedic joint replacement applications such as hip and knee implants and found that UHMWPE-PEEK pair has similar or better performance than that of the gold standard UHMWPE-CoCr pair.”

Related Content

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

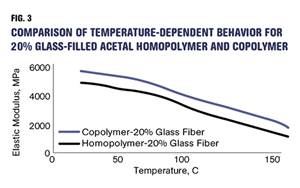

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MorePrices of Volume Resins Drop

Price relief is expected to continue through the fourth quarter for nine major commodity and engineering resins, driven by widespread supply/demand imbalances.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

(2).jpg;maxWidth=300;quality=90)