Growth Rate of Bioplastics Higher than Overall Plastics Market Growth

nova-Institute reports that the for the first time, the growth rate of biobased polymers exceeds that of the overall plastics market growth.

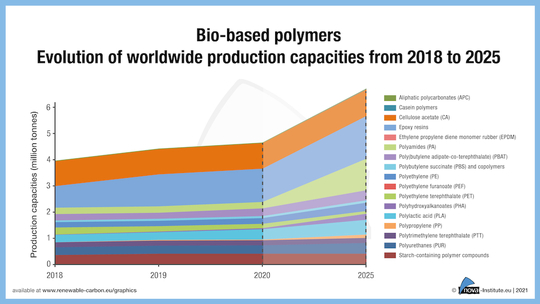

A new market and trend report from German-based researcher nova-Institute characterizes the year 2020 as very promising for biobased polymers. Sold-out PLA in 2019 led to the installation of increased capacities, PE and PP made from biobased naphtha are breaking ground, and future expansion for biobased polyamides/nylons as well as for PBAT, PHAs and casein polymers is on the horizon. A lower production was only observed for biobased PET.

“Bio-based Building Blocks and Polymers – Global Capacities, Production and Trends 2020–2025” from the international nova biopolymer expert group shows capacities and production data for all biobased polymers in the year 2020 and a forecast for 2025.

Several global brands are already expanding their feedstock portfolio to include, next to fossil-based, sources of renewable carbon, CO2, recycling and especially biomass, increasing the demand for biobased as well as biodegradable polymers. Nevertheless, at the same time, there is a lack of support from politics, which still only promotes biofuels and bioenergy.

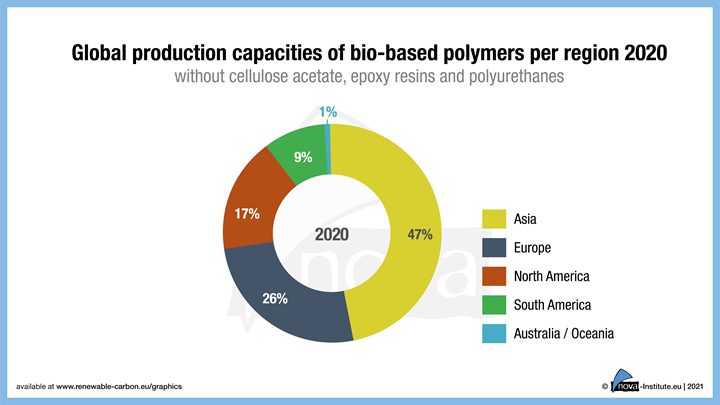

In 2020, the total production volume of biobased polymers was 4.2 million tonnes, which is 1 % of the total production volume of fossil-based polymers. For the first time in many years, the CAGR of 8% is significantly higher than the 3-4% of the overall growth of polymers, and this is expected to continue until 2025.

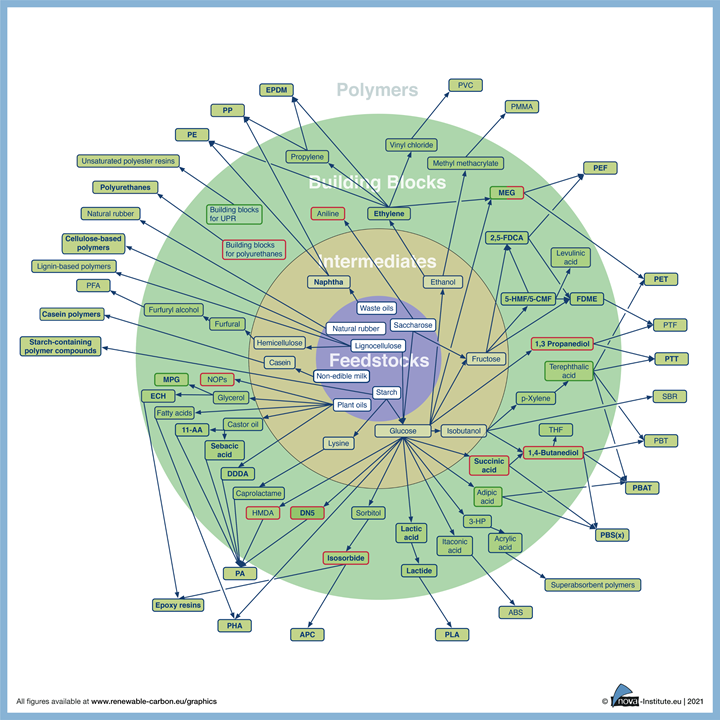

Overall, the global land requirement for bio-based polymers is only 0.006 % of the global agricultural land. The major biomass feedstock used for bio-based polymer production is glycerol as a biogenic by-product (37 %).

In the annually updated market report for the year 2020, a total of 17 biobased building blocks and 17 polymers are described, in addition to comprehensive information on the capacity development from 2020 to 2025 and production data for 2020 per bio-based polymer. Furthermore, the issue includes analyses of market developments and producers per building block and polymer, so that readers can quickly gain a comprehensive overview of current developments that goes far beyond capacity and production figures. As an additional bonus the report provides a detailed, comprehensive expert view on biobased naphtha. Finally, the deep insight into manufacturing companies introduced in 2018 has been comprehensively updated and now shows 174 detailed company profiles – from startups to multinational corporations.

It is interesting to note that the increase in production capacity from 2019 to 2020 is mainly based on the expansion of PLA and PBAT production in Asia and the worldwide epoxy resin production. Also, increased and new production capacities for polybutylene succinate and copolymers (PBS(X)) and biobased PE and polyurethanes were reported in 2020. Especially polyamides/nylons and PP will continue to grow significantly (about 36 %) until 2025. While capacities for PHA will grow in Asia and North America, casein polymers in Europe will increase by 32 % until 2025, followed by increases in PE in South America and Europe, PLA mainly in Europe and PBAT in Asia with about 8%.

The data published annually by European Bioplastics (http://www.european-bioplastics.org/market) are taken from the market report written by biopolymer expert group of the nova-Institute, but with a smaller selection of biobased polymers. The corresponding authors are from Asia, Europe and North America.

Related Content

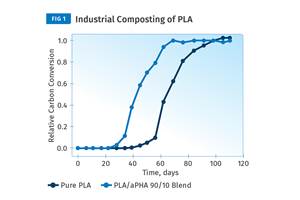

Blend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreCJ Bio’s Amorphous PHA Demonstrates Excellent Biodegradability in Marine environment

The tests of the bioplastic, a semi-crystalline PHA and a PLA were conducted by the national Korean testing agency (KCL)

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More