Study: 3D Printing Helps Strengthen Supply Chains

HP’s Digital Manufacturing Trend Report finds that companies are increasingly investing in advanced 3D printing solutions that provide the agility, speed, and flexibility necessary to grow their business.

During its global Innovation Summit, HP revealed a new study delivering insights and looking at trends in industrial 3D printing.

Surveying thousands of manufacturing executives across the world, HP’s Digital Manufacturing Trend Report finds that companies are increasingly investing in advanced 3D printing solutions that provide the agility, speed, and flexibility necessary to grow their business and become more resilient in an ever-changing environment.

One of the key insights from the global manufacturing industry is that regardless of sector or location, companies are looking to 3D printing to strengthen their supply chains, become more agile, and create more innovative product development and manufacturing strategies. This is underscored by a rising investment in 3D printing, support for 3D printing as a viable alternative to traditional manufacturing, and a greater desire for closer ecosystem collaboration to drive adoption.

Manufacturing decision makers also see opportunities for accelerated innovation, recognizing that 3D printing is uniquely suited for the mass personalization of new products, and by also reducing waste and promoting a more sustainable economy.

Highlights from the report:

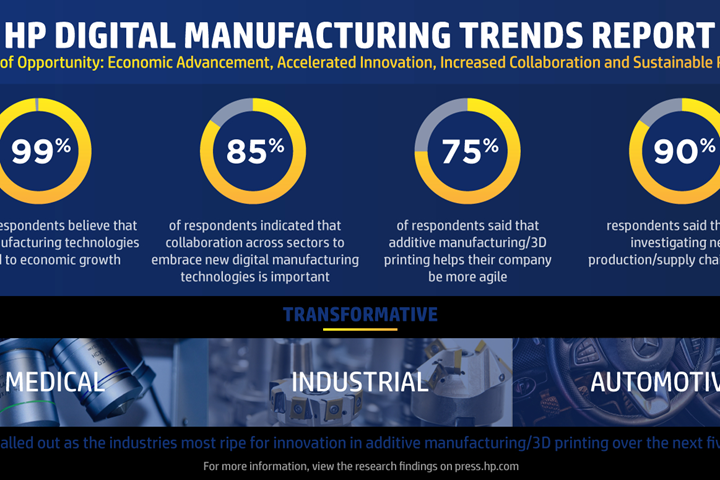

- 99% of global respondents believe that digital manufacturing technologies can lead to economic growth.

- 89% of respondents are looking to evolve their business models because of the current world business environment.

- Over the next 12 months, 71% plan on investing in digital manufacturing technologies, and over four-in-five respondents (85%) indicated that their company plans to increase their additive manufacturing/3D printing investment.

- Three-quarters of respondents said that additive manufacturing/3D printing helps their company be more agile, is a viable alternative to traditional manufacturing, and is a backup to traditional manufacturing.

- Over nine-in-ten respondents said they are investigating new production/supply chain models, with 59% evaluating hybrid models and 52% looking into localized production.

- 91% of respondents want to explore the innovation that mass customization provides and believe it could be applicable to their business if parts could be personalized through 3D printing/additive manufacturing.

- Medical, industrial, and automotive were called out as the industries most ripe for innovation in additive manufacturing/3D printing over the next five years.

- The top barrier to entry in the additive manufacturing/3D printing entry for respondents is finding a qualified workforce.

- The top ways that additive manufacturing/3D printing can reduce waste and promote a circular economy are reducing the amount of materials used and better matching supply and demand, followed by shortening and simplifying traditional supply chains, and improving service options that can prolong the life of products.

- 90% of respondents said that the recyclability of additive manufacturing/3D printed powders and parts is important.

The HP Digital Manufacturing Report is a global study by HP Inc. It was conducted by SME Media/Research across three continents and nine geographic areas including Canada, China, France, Germany, Japan, Mexico, Singapore, the UK, and the U.S. Fieldwork was conducted from July 28 – August 11, 2020 across 2,175 3D printing and digital manufacturing decision makers.

A new HP global study examining the current state and future outlook for digital manufacturing technologies such as industrial 3D printing.

Related Content

-

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

.png;maxWidth=300;quality=90)