Additive Manufacturing with Plastics

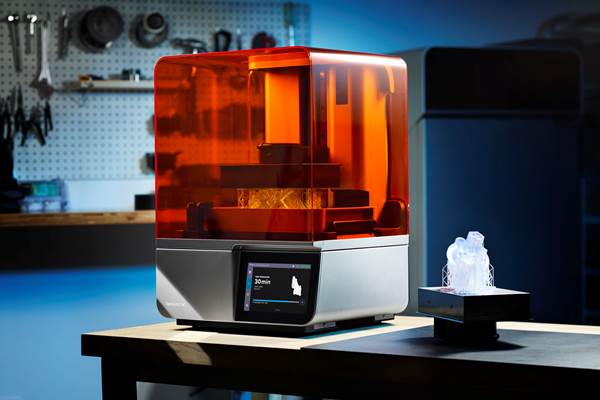

Additive manufacturing or 3D printing in the plastics industry involves the creation of components without dies or tooling—or the fabrication of tooling itself—for use in prototyping, bridge production, or short-run production. Common types include stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), and digital light process (DLP). Learn more at What Is Additive Manufacturing?

ESSENTIAL READING

VIEW ALL5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

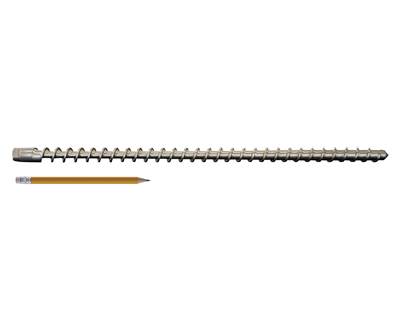

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

Read MoreLatest Additive Manufacturing News And Updates

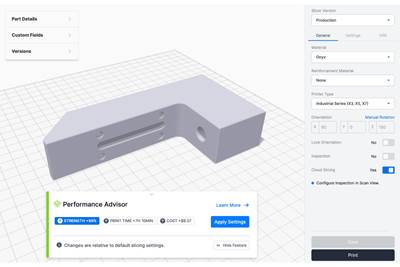

Software Guides 3D Print Settings Independently of Use Case

New software feature in Eiger predicts additive manufactured part performance.

Read MoreMechnano, Bomar introduce T50B low-viscosity masterbatch for 3D resins

T50B masterbatch by Mechnano, in partnership with Bomar, streamlines AM resin development, resolving CNT dispersion issues and elevating mechanical performance while catering to various printing technologies

Read MoreArizona City Will Try Out 3D Printers That Recycle in Pilot Program

Surprise, Arizona, will be implementing Automedi printers for public use.

Read MoreX-axis Gantry Toolchanger Enables Rapid Printing of Heterogeneous Materials

FT400 is the first industrial printer available from the Forivory brand.

Read MoreSmall-Footprint SLS Machine Can Operate in Where Space is Tight

A new Powder Recycling Station (PRS) is an optional accessory available in 2024 which works in tandem with the printer to automatically recycle unused powder currently in the system and mix it with fresh material.

Read More3D Systems’ Accura AMX Resin Withstands Harsh Thermal Environments

Formnext 2023: The resin material is well suited for the testing of high-temperature components in applications such as HVAC, consumer appliances, motor enclosures, fixtures, mounts, stators, molding/tooling and more.

Read MoreFeatured Posts

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreAdditive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read More5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

Read MoreGetting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

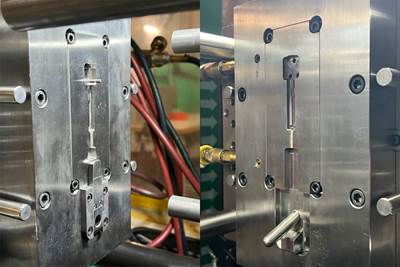

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreFAQ: Additive Manufacturing

Do I Need Additive Manufacturing Skills in My Business?

Essentium announced the third in a series of findings from independent global research on the current and future use of industrial 3D printing. The survey found an increasing need for more education, skills, and training across manufacturers’ organizations. Even as the industry moves towards large-scale AM, 28% of manufacturers reported their personnel lacked AM skills.

In recent years, it has become apparent that additive manufacturing—aka 3D printing—is destined to have a role in plastics mold making, owing to cost and lead-time advantages over conventional subtractive manufacturing—CNC machining—and unique abilities to produce complex internal tooling geometries such as conformal cooling channels.

What is Formnext Chicago?

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois.

Formnext Chicago is part of a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

Here is the full lineup of Formnext events in North America:

- Formnext Forum Austin took place in August 2023 and will return to Texas in 2026.

- Additive Manufacturing Sector Powered by Formnext at IMTS in 2024

- Formnext Chicago in 2025

Additive Manufacturing Supplier Categories

- Clamps, Holding Devices

- Additive Manufacturing (3D Printing/Prototyping Materials)

- Automation/Systems Integration

- Speed, Drive Controls

- Recording Instruments

- Troubleshooting, Problem Solving Systems

- Recycled/Reprocessed Materials--Ground Flake Form

- Machining, Drilling, Routing Equipment

- Machining, Routing Software

- Materials Formulating Systems

- SPC, SQC Systems

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

- Liquid Resin Filtration Materials, Equipment

- Assembly Robots and EOAT

- Flow Monitoring/Control Devices (for Liquids)

- Bending, Heat-forming Equipment

- Maintenance Management Systems

- Core Materials

- Timers

- Ultrasonic Cutters

- Prototyping Services

- Cutting Tools

- ISO 9000 Software

- Stock Shapes--Rod, Tube

- Recycled/Reprocessed Materials--Bale or Bulk Form

- Particle Screeners, Classifiers, Separators

- Job Quoting, Cost Estimating and Accounting Systems

- Stock Shapes--Film

- Dewpoint Monitors/Moisture Analyzers

- Fasteners

- Spray Painting Robots and EOAT

- Scheduling, MRP, Production and Inventory Management Systems

- Fluid-jet Cutting Systems

- Consultants - Design, Manufacturing, Purchasing

- Pressure Controllers, Monitors

- Temperature Controllers, Monitors

- Color Matching/Formulating Systems

- Temperature Pyrometers, Sensors, Thermocouples

- Design of Experiments (DOE) Software

- Motion or Position Controls

- Part or Sprue Removal Robots and EOAT

- Screw Design/Analysis Software

- Sequence Logic Controls

- Level Sensors and Controls

- Recycled/Reprocessed Materials--Pelletized Form

- Closed-loop Process Control Systems

- Stock Shapes--Sheet

- Machine Monitoring/Alarm Systems

- Environmental Monitoring and Analysis

- Biodegradable, Photodegradable Resins and Compounds

- Lasers (for Cutting, Machining, Welding)

- Pressure Sensors, Transducers

- General Purpose Robots and EOAT