Auxiliary Equipment: Sanitizing System Stops Particulate, Dust from Accelerating COVID-19 Virus

New machine features a multi-stage air circulator, scrubber, and sanitizer that traps airborne particulate and then kills any viral matter automatically with a multi-staged ultraviolet system.

Novatec has introduced a patent-pending ScrubX Sanitizing System to remove and sanitize dust and plastic particulate that may have been exposed to harmful airborne pathogens. Individual units provide 200 cfm of airflow and can provide dust/particulate control for up to 3000 ft2 of interior space.

The machine was invented to help mitigate the level of the novel Coronavirus, which could be present in factory air by removing the dust and particulate from work areas along with any pathogens that might be present.

“It has been proven that viruses can easily attach to dust and particulate which provides a media for the airborne pathogens to stay suspended and to circulate in factory air longer than typical aerosol transmission," notes Mark Haynie, Novatec’s dryer product manager. “While most airborne viruses can circulate for up to five hours, with dust and particulate hanging in the air, the virus could stay present for 48 hours or more.”

Novatec's ScrubX features a multi-stage air circulator, scrubber, and sanitizer that traps airborne particulate and then kills any viral matter automatically with a multi-staged ultraviolet system. Airflow is moved and directed by a regenerative blower to enter through an intake that can be oriented to provide maximum air circulation.

The air enters a cyclone designed to remove most of the dust and then directs it to a collection container that has ultraviolet C (UVC) germicidal lamps with 2-4 mJ/cm² intensity. Any dust that is too fine to be removed by the cyclone enters a second-stage filter, which has more UVC lamps and includes a 0.1-micron ultra HEPA filter that removes dust and small pathogens, including coronavirus.

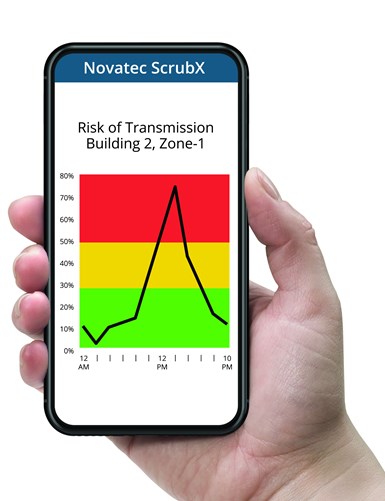

A built-in control designed by sister company MachineSense LLC automatically measures air quality index, filter status, particulate levels, and more for complete remote monitoring. The control system receives feedback from particulate monitoring sensors located in dust prone areas.

Both mobile and stationary units are available. Mobile units can be easily moved throughout the factory, or stationary units can be installed in a fixed location, inside or outside of the building.

"Novatec is hoping their technology will get more people back to work safer and faster than thought possible," states Novatec's CEO and Managing Partner, Conrad Bessemer. Bessemer also co-founded MachineSense, which has introduced FeverWarn, a low-cost, advanced, infrared temperature scanning system that can be used to help detect and screen for COVID-19.

(2).jpg;maxWidth=300;quality=90)