High-Performance LLDPE Film Grades

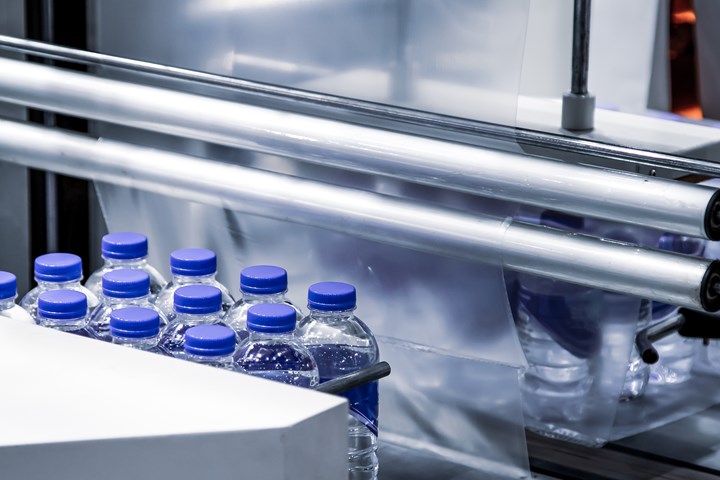

ExxonMobil’s new series Exceed XP 7 hexene LLDPE resins boast “never seen before” levels of performance.

A new series of hexene LLDPE resins produced with a proprietary catalyst is said to offer “never seen before” levels of performance that enable converters to create innovative new films for stretch hood packaging, collation shrink, primary packaging, and greenhouse applications that previously were not possible. The Exceed XP 7 series is the newest addition to the Exceed XP line of high-performance LLDPE film resins from ExxonMobil. Exceed XP 7021 and XP 7052 reportedly deliver remarkable mechanical performance with a combination of low density and fractional melt index (MI).

As such, they are said to offer the value chain a combination of attributes that is currently not available in a single resin. This includes high levels of elasticity and holding force, puncture energy (up to 2.3 J/mil) and dart impact resistance (up to 900 gm on a 25.4 micron film). Moreover, ExxonMobil research and tests indicate that Exceed XP 7021 and XP 7052 also offer a combination of fractional MI and low density (0.911- 0.912 g/cm³) that is not available in the market today. This makes films with enhanced bubble stability and creates opportunities to increase output for converters.

“Extending the extreme performance of our Exceed™ XP portfolio to ‘never seen before’ levels, these new grades are designed to help the value chain create innovative solutions to meet specific applications needs,” said global PE new products marketing manager Michael Vinck, “We are currently working closely with our value chain partners to develop film formulation solutions that many in the industry believe would only happen in the future but which, through collaboration, we are making possible today.” Included are:

▪ Stretch hood films combine HEVA equivalent elasticity with high holding force for pallet stability. Thanks to the performance of XP 7021 and XP 7052 a compromise is no longer necessary, helping to enhance pallet stability for product protection and safety. The new performance PE grades also offer high puncture and dart impact resistance for less breakage, while delivering low haze which improves barcode and QR code reading. Ease of processing leads to excellent gauge control and the high elasticity provides forgiveness for less than perfect gauge profile. Said Vinck, “Tests undertaken in collaboration with Signode, an industry-leading OEM and manufacturer of Lachenmeier stretch hood equipment, resulted in a single resin Exceed XP 7-based solution. Although the film was co-extruded, it is a mono-material PE film contributing to its recyclability1.”

▪ Collation shrink films at low temperatures that offer potential energy savings from lower energy use. Manufacturers can now offer their customers energy savings opportunities thanks to XP 7021 and XP 7052 which enable high shrink speeds at temperatures as low as 120 C.248 F. Films can protect sensitive products from excessive heat. The removal of cardboard trays is possible in many applications. Said Vinck, “Films which exhibit MD and TD shrinkage at low temperatures, and can be processed on traditional blown film lines, are a rarity in the market.”

▪ Primary packaging films at low seal initiation temperatures for fast sealing. Made with XP 7021 and XP 7052, such films can help seal packages at low temperatures without blocking issues. Customers can reduce antiblock levels to improve coefficient of friction (COF) control and optical properties for better brand promotion. Designed for low seal initiation temperature packaging applications, these PE polymers also enhance packaging toughness with best-in-class flex crack, extreme dart and puncture, while offering good optical properties. Said Vinck, “Flex-crack resistance is so high, tests undertaken by ExxonMobil resulted in an average of 1 hole per ten thousand cycles. The combination of fractional MI and a 0.912 g/cm³ density helps prevent seal thinning without the addition of LDPE when compared to conventional sealing resins.”

▪ Greenhouse films with remarkable softness and clarity combined with dart and puncture resistance for integrity. Greenhouse films that are tough, clear, and soft can now be fabricated by converters due to the extreme dart and puncture resistance offered by XP 7021 and XP 7052. As a result, the greenhouse films have better integrity, reducing the risk of failure and premature breakage during installation and in-service. Said Vinck,“Films made with these new grades offer farmers the opportunity to enjoy longer and better growing conditions for potentially higher crop yields, helping to meet the growing population’s need for food.”

Related Content

The Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

Read MoreThe Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More