KraussMaffei’s Integrated Molding Cells Focus on Five Technologies

High-speed machines, LSR, composites overmolding, Industry 4.0 and more showcased.

KraussMaffei will feature presses for the large packaging market, IML, lightweight thermoplastic composites, LSR, rapid heat/cool molding, and Plastics 4.0.

• High-speed medium-size machines: A new “speed” option for medium-sized GX two-platen presses from KraussMaffei suit them to large packaging and logistics components. The GX-900 at NPE2018 has clamping speeds as low as 0.45 sec., with injection-speed options ranging up to 700 mm/sec. Faster cycles are assisted by addition of an electric screw drive and the HPS high-performance barrier screw. The machine at NPE is molding two 5-gal paint pails with IML—said to be an unusual feature for this market—in under 14 sec.

• Liquid silicone rubber: KraussMaffei is molding LSR medical dosing caps, or “duckbills,” on its PX 51-55 SilcoSet all-electric machine. The modular press has hydraulic nozzle-contact force, special screw seals, and spring-loaded check valve.

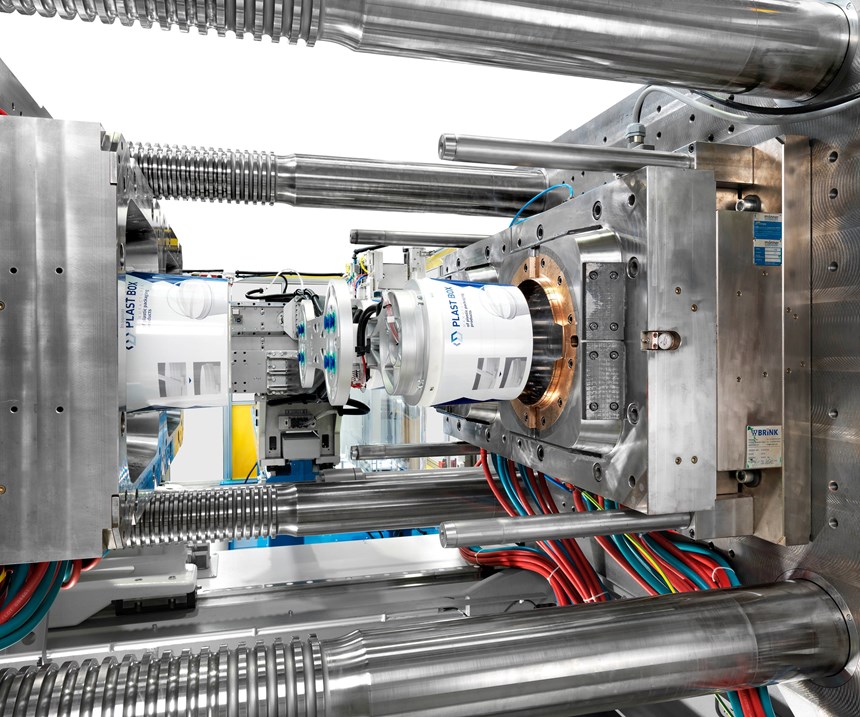

• Composites overmolding: KraussMaffei is adding a wrinkle to its FiberForm thermoplastic composite technology by overmolding composite sheets with both a rigid thermoplastic for functional purposes and soft-touch TPE for consumer comfort, producing an auto armrest on a GWX 450 press with a swivel plate.

• Rapid heat/cool molding: KM’s booth features Roctool technology for heat/cool molding with inductive mold-heat balancing. A 16-cavity tool will produce plaques with 16 different surface qualities—glossy, matte, hologram, etc.—in a single shot. This cell also utilizes the LRX 150, one of a new generation of KM linear robots, which has 15-kg (33-lb) payload capacity and can perform bagging and packaging of parts within the enclosure of the molding machine.

• Industry 4.0: One of the four pillars of Industry 4.0 (which KM refers to as Plastics 4.0), is “smart machines” that can regulate their own processes. In this category, KM is featuring its APC+ adaptive process-control software that is intended to ensure consist parts production by adjusting to changes in material viscosity and ambient conditions. The “plus” enhancement to the APC algorithm is the addition of a library of materials data—particularly melt density and melt compressibility under pressure, which are critical to consistent cavity filling and packing.

KM is also highlighting its DataXplorer software that provides a nearly microscopic look at the process, enabling users to respond to unclear fault patterns. Depending on how the machine and mold are equipped with sensors, DataXplorer can display up to 500 high-resolution signal paths.

Related Content

-

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

-

How to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

(2).jpg;maxWidth=300;quality=90)