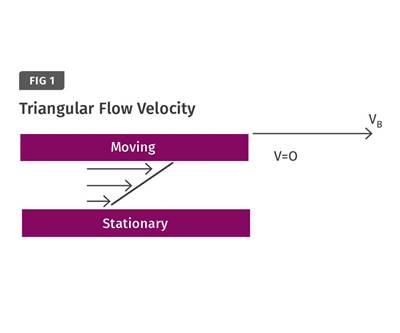

Extrusion Know How

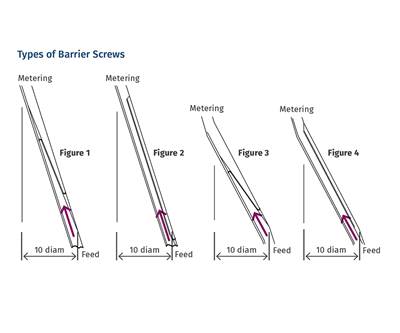

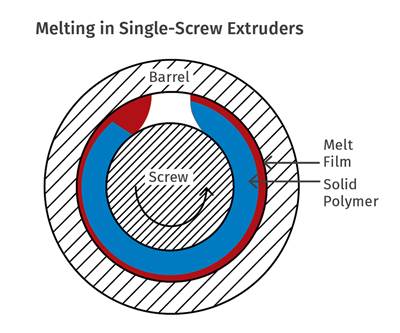

Sizing the Barrier Gap

Here’s a less complex way to properly size the barrier gap for barrier screws.

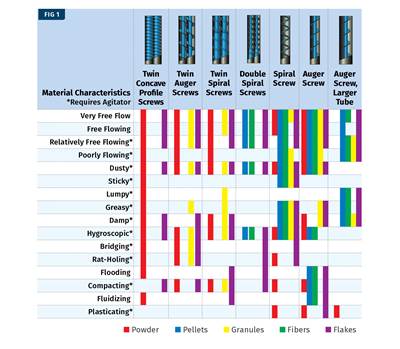

Read MoreOptimize Feeding to Get More Money in Twin-Screw Compounding

Follow these practical examples to improve the feeding efficiency and productivity of your process.

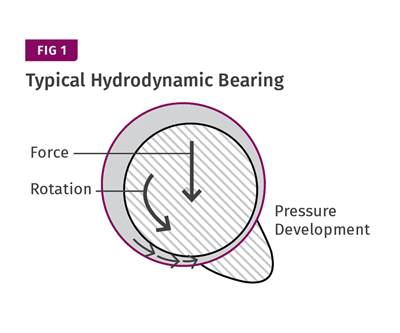

Read MoreHow ‘Hydro Wedges’ Reduce Screw Wear

Using them only in the melting section provides for greater design freedom and negates the impact these devices can have on output and melt temperature.

Read MoreExtruding with Fillers

You can use the reference point from processing unfilled polymer to determine whether you can run filled resin on your current system.

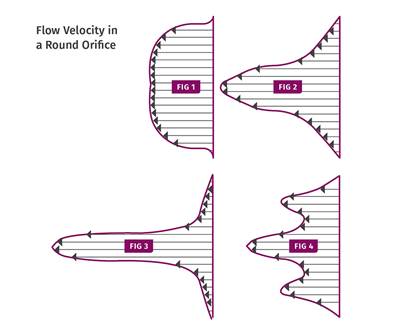

Read MoreDon’t Build In Melt-Temperature Variations

It’s not unusual for polymer to exit the extruder with a uniform melt temperature, only to be fouled up by downstream flow pipes and the like. Here’s how to avoid this.

Read MoreHow to Collect & Interpret Process Data in Extrusion

The first installment of this three-part series focuses on proper use of a data- acquisition system.

Read MoreHow to Collect & Interpret Process Data in Extrusion: Part 1

The first installment of this three-part series focuses on proper use of a data- acquisition system.

Read MoreWhich Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

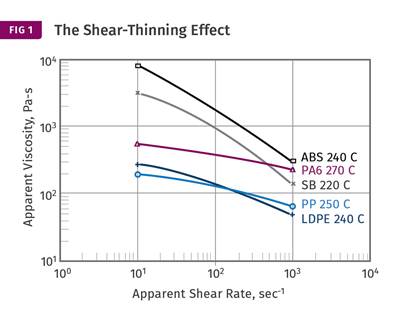

Read MoreExtruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

Read More

(2).jpg;maxWidth=300;quality=90)