processing tips

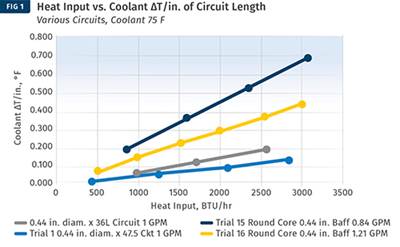

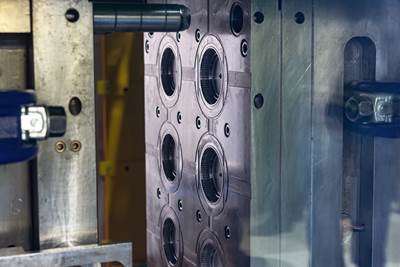

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

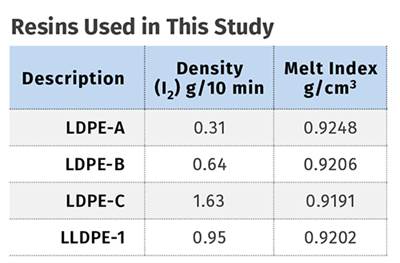

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

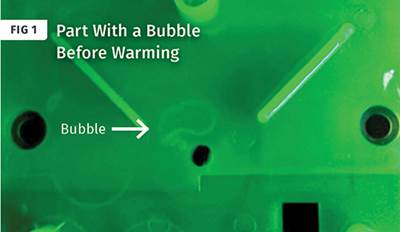

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

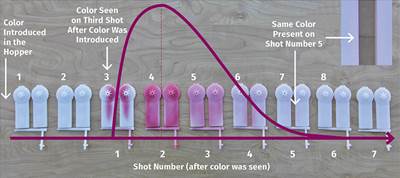

Read MoreThe Importance of Gauging Residence-Time Distribution—Part 2

Each molecule in the molded product can have a different residence time. This variance is reflected in the Residence-Time Distribution, which you can learn how to determine below.

Read MoreTroubleshooting Pressure Fluctuations in Piston-Type Melt Filters

Piston filtration offers many advantages over other systems. While pressure fluctuations could be regarded as their weakness, there are many ways to avoid them, both from the mechanical and the process side. Small adjustment can make a huge difference in the overall performance and efficiency of the system.

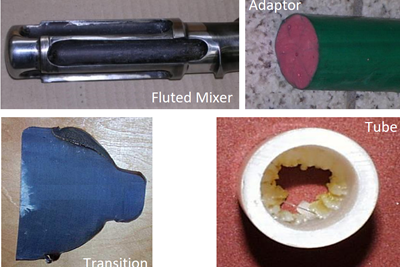

Read MoreWhen to 'Adapt,' When to Retool?

That is the question pipe and tubing processors typically confront when they specify a line for one product, only to have to add to the product mix when business conditions change. Here are some tips to guide you to the right answer.

Read MoreThe 'Butterfly Effect' in Injection Molding—A Connected Process

In injection molding, a seemingly minor change in a setpoint can have a significant impact on part quality and process robustness and repeatability. That’s why Scientific Molding focuses on process outputs, not setpoints.

Read MoreSolving the Bane of Stretch-Blow Molding: Off-Center Gates

There are many reasons why off-center gates happen, and processors should be aware of all of them to quickly find the ones causing the problem.

Read More