AUXILIARIES AT NPE: More Control, Flexibility, And Efficiency

These are key trends in the many kinds of auxiliary equipment displayed at this month’s show. You’ll also see equipment designed to be virtually ‘foolproof.’

Modular designs, updated controls, and added sensors for greater process transparency are featured prominently across all auxiliaries that will be on display at NPE2015, March 23-27 in Orlando, Fla.

DRYING

Flexibility and efficiency are the order of the day in drying systems, with suppliers at NPE2015 showcasing designs that allow processors to ramp up capacity as needed with energy-smart operation regardless of total drying output.

At NPE2012, Novatec introduced the Moisture Master Inline Moisture Analyzer, and it will once again highlight the innovative technology that reportedly produces more accurate moisture measurements than offline analyzers. Novatec notes this higher accuracy is a result of the ability to limit process variations and provide sample readings with much greater frequency.

Typically a processor might specify hourly sampling, or even once per shift. But because the Moisture Master doesn’t pull sample pellets out of the process flow, the readings are much more accurate and frequent. The sensor measures a depth of 1 cm around the circumference of the hopper exit tube for a length of 6 in., taking a reading every second, so that in 1 hr, it provides 3600 discrete readings of moisture content as pellets enter the process.

Because of the differing moisture content in the pellets in the hopper, those readings will show variability, but the controller creates a statistically relevant trend line that correlates to a trend line created by any high-quality offline analyzer.

Wittmann Battenfeld’s material-handling systems and other auxiliary equipment will be operating in its booth, spread among six injection molding work cells. In drying, the company will feature the Aton Plus segmented-wheel dryers. These feature a new touchscreen display and built-in energy-saving functions, including the 3-save process and EcoMode.

Also on display will be the FC Plus for Drymaxx battery dryers. This new option for extending the functionality of a frequency-controlled battery dryer allows adjustment of dry-air volume and contributes significantly to additional energy savings.

The Conair Group will bring its MicroWheel desiccant dryers to NPE, billed as a good choice for medical processors and those running small quantities of expensive engineering resins. Available in two models, the dryers use brushless blowers with built-in speed control, allowing easier programming and the ability to deliver the correct amount of process-air flow to dry different resin volumes. Hopper capacities range from 0.2 to 1 ft³. Including the hopper, the dryers range in height from 19.5 to 27.7 in. The largest unit weighs in at 106 lb.

The new E-Plus Series dryers from Dri-Air Industries are said to offer faster, more complete drying with unmatched energy efficiency. Their novel parabolic tower design, unique heater configuration, and optimized airflow are said to maximize moisture pickup for ultra-low dewpoints, faster drying, and dramatically reduced regeneration energy usage (see February Keeping Up).

After setting up a new U.S. subsidiary in Columbus, Ohio, at the end of 2014, Italian auxiliary equipment supplier Moretto SpA will further reinforce its North American presence at NPE2015, showcasing its Eureka high-volume PET drying system stateside for the first time. Eureka, which consists of the Flowmatik airflow management and distribution system, OTX drying hopper, and X Max drier, offers throughputs ranging from 22,000 to nearly 27,000 lb/hr. Moretto says the system has up to 56% lower energy consumption than traditional drying systems.

The core X Max drier is based on Moretto’s patented X technology and incorporates a multi-bed desiccant system with a constant dewpoint of -65 C to -85 C. Moretto notes that despite being twice the size of conventional beds, the dryer can run without cooling water or compressed air for the changeover valve, and it also offers complete energy recovery, reclaiming heat from cooling of the bed during desiccant regeneration. At last fall’s Fakuma 2014 show, Moretto added a multi-stage centrifugal blower to the X Max drier—a technology developed in conjunction with Padua University.

Since the Eureka system’s debut at K 2010, Moretto reportedly has sold some 60 systems, 27 or so in the U.S. The latter are used primarily for PET fiber and carpet materials, but bottle preforms are said to be next. One large U.S. carpet maker has a Eureka system for processing 13,000 lb/hr, using 32 OTX hoppers and 10 X Max dryers.

New MJ5-i series dehumidifying dryers from Matsui America utilize the company’s iplas technology to automatically determine and maintain optimal drying conditions while reportedly reducing energy consumption by up to 75% (see Keeping Up report for more details).

Universal Dynamics Inc. will showcase its AutoMate Multiple Material drying technology. The system’s individually packaged drying modules consist of hopper, heater, local control, dry-air supply/return manifold, and a stand, allowing processors to custom configure any grouping. Each hopper can be selected for specific material-usage rates and drying requirements, with individual microprocessor controls for airflow management, energy optimization, automated start-up, and over-drying protection.

Una-Dyn notes that the individual drying hoppers can be automatically set for optimized airflow and drying, resulting in homogeneous thermal conditions and the lowest residual moisture. The entire central drying system can be optimized by adjusting central dryer performance in response to cumulative multi-hopper system performance.

AutoMate Systems equipped with FocusFit controls allow communication between the central dryer’s microprocessor and each hopper control, with operator interfaces at both locations. Central systems can be configured with dual dehumidifier units for a ready-to-go backup.

New AutoMate hopper airflow-control valves dial in the drying air supply to properly dry a variety of resins while optimizing the total air consumption for minimum energy consumption. Operators can choose between local control for each hopper and a central graphic interface for all control functions.

Una-Dyn is also introducing the Vantage series portable dryer line featuring its maximum-duty rotary air-distribution valve. Positively ported and proofed, the valve is said to provide spikeless changeovers and flatline low-dewpoint performance.

The unit’s regeneration system uses condition-controlled heat profiles for reduced energy consumption, and the desiccant tower design and construction reportedly provide steady-state, low-dewpoint performance regardless of ambient climate. Una-Dyn says this portable dryer line targets applications up to 200 lb/hr, and can be furnished complete with an on-board inbound/outbound loading system.

LOADING & FEEDING

Novatec is expanding its conveying equipment offerings, adding the GSL-12 brushless loader to the GSL-19. Both are billed by Novatec as the only loaders with a “No Exclusions,” five-year warranty. The new GSL-12 loader’s body pivots forward while its lid pivots back, easing filter access. Both loaders have a powerful blowback system, according to Novatec, and they both utilize a simple pendant control supplied as standard. With the pendant, all loader functions can be changed at floor level. The GSL-12 and GSL-19 are available in either hopper- or machine-mount models. To further entice processors, Novatec is offering a $200 trade-in on competitive loaders. The company says it will pay any related shipping costs on the old loader.

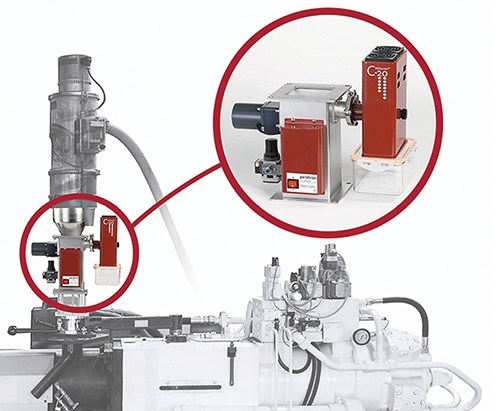

Novatec will also be showing a conveying pump at its booth equipped with patented predictive-maintenance technology from Prophecy Sensorlytics (see February Close-Up).

Motan Inc. will introduce to North America the Metro G material loader range, which combines technologies from Motan and sister company Colortronic. Its debut was at last fall’s Fakuma show in Germany (see Oct. ’14 Keeping Up). The Metro G can be converted into a cleanroom-ready unit by adding special vacuum diaphragm valve, while a dust-removal module eliminates fines, essential for processing critical engineering plastics where no dust is allowed.

A new vibratory-feeder-based blender from Process Control Corp. comes with a color touchscreen control and can be equipped with an integral weighed downcomer for extrusion control. Each hopper and feed system is mounted on a load cell, making the vibratory system more accurate than a batch blender and almost as accurate as PCC’s flagship PCC X-Series continuous blender (see February Keeping Up).

Load cells lend greater accuracy for loss-in-weight feeders on Coperion K-Tron’s Smart Flow Meter K-SFM-350-B. On this feeder, bulk material flows by gravity into the upper measuring channel—an inclined chute mounted on a load cell, where the force acting perpendicularly on the chute is measured as mass. It then flows into the lower, vertical channel, where the impact is measured by a second load cell to determine the velocity or acceleration rate. From the signals of these two sensors, the flow rate is determined per unit of time.

The company will also highlight a modular loss-in-weight feeder it says is suited to materials with varying bulk density. The single-screw feeders handle powders, granules, pellets, and other free-flowing materials. Coperion K-Tron notes that the twin-screw elements are suitable for floodable powders and sticky or hard-to-flow materials. Units on display at NPE2015 include the S100 single-screw feeder for 0.4 to 560 ft³/hr and T35 twin-screw unit for 0.04 to 88 ft³/hr. Both will be equipped with patented Smart Force Transducer weighing technology.

Riverdale Global’s latest enhancement to its “no spill/zero waste” system for the supply and dosing of liquid color is the Riverdale Gravimetric Stand (RGS). With the RGS, a liquid-color drum is mounted on a self-calibrating loss-in-weight scale that continually reports the weight of the contents to the controller to ensure the target letdown ratio is maintained. In this system, the color container is never opened, while drip-proof connections keep the color completely contained (see February Keeping Up).

The Flexwall Plus family of feeders from Brabender Technologie is now available with optional independent paddle agitation. This allows the unit to feed even more demanding ingredients than previously possible. This change also further simplifies screw removal from the rear.

Meantime, Brabender’s new MiniTwin Feeder now includes a lightweight precision brushless DC motor, easy disassembly, and standard pharmaceutical-grade finish. The feeder is capable of rates as low as 50 g/hr and is available in both volumetric and loss-in-weight models.

MATERIAL CONVEYING

Several auxiliary suppliers will highlight resin-conveying technology meant to eliminate the possibility of operator error when assigning materials to machines. Conair will once again feature its Material Vision Proofing (MVP) system at the show, initially featured at NPE 2012. That system includes a motorized camera that automatically confirms that the connection between material sources and destinations has been made correctly and conveying can begin.

Una-Dyn’s automatic coupling unit, called Easylink, is a fully automated material-line routing system that provides vacuum-tight connections between selected sources and destinations. Coordinated with sequential batch vacuum conveying systems, it provides proofed connection, conveying, and line purging.

Una-Dyn’s new Ryng low-profile inline inventory unit measures the real-time loading of resin. This device totals the amount of resin consumed per user-designated time frame. The standard central control panel can monitor up to 80 Ryngs, and an optional local keypad can be used on individual receivers.

Motan will highlight its SilentLine double-walled material feed-line system, which comes with a guaranteed minimum noise reduction of 12 dBA. SilentLine can be combined with the company’s IntelliFlow system for an additional sound reduction of up to 6 dBA. It also detects line leaks so faulty pipe sections can be easily identified and replaced. In addition to sound management, the double-walled pipeline provides thermal insulation, allowing dried material to cool less quickly during the conveying process.

Sterling will introduce its VP Series vacuum pumps, touting their flexibility. The new series, which is available in open- or closed-loop designs, offers more than five different filter types that can be used to convey pellets or dusty regrind over short-to-medium distances. The pumps convey continuously using an atmospheric relief valve to provide high conveying rates over long distances.

Coperion K-Tron’s dual-blower rail-unload system pneumatically transfers pellets, powder, and granular material from railcars at rates above 120,000 lb/hr. Dual-blower systems are available in up to 10-in. line sizes. A vacuum blower draws material from the railcar to a self-cleaning Coperion K-Tron Filtair filter receiver, which separates the product from the conveying air. Mounted below the receiver is an Aerolock rotary valve that meters material into the pressure side of the system for delivery to storage. The system also includes a railcar hatch-vent filter and nozzle kit, control panel and motor starters, and line adapters and hoses.

Schenck Process will feature the FulFiller Container Loader, a high-speed, belt-based loader for filling 20- or 40-ft containers with pellets in 10 min or less for a 20-ft container.

Moving material invariably means creation of fines, angel hair, and dust, so several technologies will be on tap at NPE2015 to promote purified pellets. For instance, the patent-pending C-20 DeDuster from Pelletron weighs only 20 lb and stands 9.5-in. tall. Pelletron says in addition to providing excellent cleaning and dedusting performance in a small footprint, the C-20 is economical. It typically processes 50-70 lb/hr. The unit was introduced at K 2013.

Pelletron will also showcase its XP-series DeDuster with automated inlet device at NPE2015. The XP-360 design, which is also patent pending, was developed for cleaning large batches of pellets at manufacturing sites with outputs from 40,000 to 330,000 lb/hr in bagging, truck, and railcar loading. Eliminating rotary valves that are normally used for feeding product into the DeDuster, the XP-360’s automated inlet deflectors move to adjust the product flow to the desired flow rate, evenly distributing pellets over the wash decks of the DeDuster.

The company will also feature its pellcon3 “gentle conveying process” in Orlando. Designed for large conveying capacities at compounders or resin manufacturers, the pellcon3 consists of three components: Strandphase, Pellbow, and DeDuster. Pelletron says combination results in gentle conveying and low attrition rates for the material, and clean pellets.

Mac Process will showcase the E-finity patented continuous dense-phase conveying system for fragile materials at NPE2015 (see Keeping Up for more information).

New angel-hair traps are available from Lorenz Conveying Products in two configurations for mounting in the material stream or at the base of the silo or storage bin .

Stray metal can wreak havoc on machines and finished parts. To help processors eliminate potential metal contamination in their material, several technologies will be on display. One is the new Xtreme metal detector from Eriez, which offers improved sensitivity and intuitive operation.

The new interface features a full keyboard, auto setup, reject log, and vivid display with design elements borrowed from smartphones. The Xtreme metal detector has greater sensitivity with its multiple frequency range and vibration immunity, according to Eriez. An integrated beacon and configurable inputs and outputs ease installation. Maintenance is simplified thanks to easier access to wiring via the device’s large control opening.

Bunting Magnetics Co. will show a variety of metal-detection, magnetic-separation, and material- handling products, including a high-intensity separation conveyor.

In designing that conveyor, Bunting said it utilized finite-element design software to maximize magnetic-field strength and create some of the highest magnetic surface intensities available. The result is an extremely strong magnetic field with a low field height for attracting and holding even small items of weakly magnetic materials.

According to Bunting, difficult and unusual items separated by the conveyor include stainless-steel razor blades, small computer screws, stainless sheet metal from computer hard drives, tiny screws from plastic chips, and green circuit boards with attached chips.

Process Control will debut its new Gravitrol Gravimetric Extrusion Control (see February Keeping Up).

PROCESS COOLING

Energy efficiency and the ability to scale up are key themes in process cooling at NPE2015, with various suppliers showing units that can grow as a processor’s cooling demands expand.

Conair will show its ESE Series EarthSmart central chillers, described as modular and scalable. That scalable design allows processors to expand up to a total of six chillers resulting in a combined cooling capacity of 960 tons (see January Keeping Up).

Conair will also highlight its EarthSmart Adiabatic Cooling Towers, which reportedly can reduce water and energy consumption while preventing process fluid contamination.

Thermal Care will present a full lineup of chilling and temperature control equipment, displaying 21 different types of units, with 11 of those making their debut (for more details see Keeping Up).

Advantage Engineering Inc. will introduce the color touchscreen Temptender control instrument for its Sentra fluid circulating temperature control unit line. It replaces the previous HE control instrument that has been used on Sentra temperature control units since 1996, of which more than 12,000 have been deployed (for more details see Keeping Up).

AEC’s Trident GS Series modular central chiller features individual circuits ranging from 50 to 120 tons of chilling capacity. Processors can parallel up to five of the circuits for a maximum chilling capacity of 600 tons. Each Trident circuit utilizes a dual-screw compressor, and all GS Series chillers, available in remote air-cooled and packaged water-cooled models, offer a leaving coolant temperature range of 30 F to 65 F.

Hooking together multiple circuits is simplified, according to AEC. After the refrigerant and water lines have been installed, drone circuit installation is a plug-and-play operation. Each circuit contains all the necessary components and programming to take over as the master unit at any time, further reducing integration and setup time. AEC notes that pump tanks are also easily integrated.

AEC’s TS Tech integrated tool-less strainer technology allows for easier maintenance and maximum uptime for each chiller circuit. Those features, combined with integrated Schrader valves for service connection and refrigerant recharging, makes the Trident easier to maintain, according to AEC.

Electronic sensors provide a digital readout of compressor suction pressure, compressor discharge pressure, condenser inlet temperature, superheat, sub-cool, pump pressure, tank level, and the temperature of fluid leaving and entering the system.

Frigel will highlight its new 3PR Intelligent Control System, which features a 7-in. color touchscreen interface, putting more data points at processors’ fingertips, according to the company. 3PR automatically adjusts the Frigel cooling system using real-time data. Frigel notes that troubleshooting features, combined with remote-access capability, help operators minimize downtime. The controller’s onboard memory further aids in troubleshooting and uptime by continuously storing key operating conditions, which can be downloaded for detailed analyses.

Frigel will also exhibit its Ecodry 3DK closed-loop adiabatic liquid cooler, the next generation of its patented adiabatic system that the company says can increase water and energy savings, while improving cooling precision, reducing maintenance, and saving space.

Engel is adding a new dimension to mold-temperature control with its e-flomo water manifold. It has electrical control valves, allowing flow rates to be adjusted and controlled automatically. Introduced at Fakuma 2014, this is an advance on its original flomo unit from 2010, which provides electronic flow monitoring with manual adjustment.

Wittmann Battenfeld’s new Tempro with direct cooling will be in operation at the show. The newest Tempro features a more compact design and enhanced heating and cooling capacities.

Frigel will also showcase its Microgel portable chillers/TCUs. The compact, portable units are available in single- or dual-zone formats with water or air cooling. Compared with central chillers, Frigel says its Microgel units save 60% of energy costs while using less space. In addition, Frigel will highlight its VFD Pump Set, and its HB-Therm and Turbogel TCUs.

A major emphasis at the booth of Single Temperature Controls will be its EcoTemp system of “passive variotherm” molding, which involves hot/cold cycling of the injection mold. Single’s economical approach—described by a company official as a “poor man’s variotherm”—is to halt the flow of cooling water during mold filling, followed by intensive cooling with water below the temperature that might normally be used for conventional constant-temperature mold cooling. The result is said to be double-digit reductions in overall cycle times (see February Close Up.)

PARTS CONVEYING

In addition to moving material around, NPE2015 will feature various technologies for transporting products after processing. Schneider Packaging Equipment Co. Inc. will exhibit laning, orienting, packing and palletizing products at the show. Schneider’s plastics-specific offerings include its two-axis servo high-speed laner, which maintains a continuous flow of product and eliminates the need for product accumulation or intermittent start/stop operations.

The company’s custom end-of-arm tooling is specifically engineered for high-speed molded parts packaging, and it can pack combo packs, including products with a complex shape that must be both tightly and gently packed. When combined with Schneider’s vision-guided robotics, the systems can locate, inspect, sort, count, orient, align, pack, close, label, and palletize molded goods.

Dynamic Conveyor will present its new Vertical Z conveyor, which allows processors to save floor space in instances where parts must be moved to a higher elevation. The DynaCon vertical incline conveyor can be custom designed to a specified height and comes in widths ranging from 4 to 60 in.

DynaCon’s Variable Height Adjustment option is available for any of the company’s straight, inclined, or Z-style conveyors. One-person height adjustments up to 15 in. are possible.

TESTING & MEASURING

Look for new material testing machines from at least three suppliers. Tinius Olsen will showcase the ST Series of electromechanical universal testing machines, featuring frames with capacities up to 67,000 lbf (300 kN) of force and digital control. They can test a wide range of materials, including films, using tension, compression, flex, shear, and peel procedures. The bench-mounted ST Series replaces the S and T Series of testers, and comes in capacities from 200 to 10,000 lbf.

There are also three higher-capacity floor models, which replace the company’s U Series, in capacities from 22,000 to 67,000 lbf. Their frame design allows the flexibility of a single test area for both tension and compression tests, and a lower bottom crosshead than the older U series models makes loading of heavier samples easier. Control of ST machines is via a Bluetooth handheld interface or a virtual machine interface running on a connected PC.

Shimadzu Scientific Instruments is expanding its Autograph AGS-X series of universal testers with four new units that boast high-level control, tight precision, and intuitive operation for a wide variety of material testing tasks. Included are tabletop units and floor models. They come standard with Shimadzu’s Trapezium X materials testing software, said to quickly obtain and display testing data in real time.

Testing Machines, Inc. will feature its new pendulum impact tester, Model 43-76, which boasts a completely new, robust mechanical design that can be easily configured for Izod or Charpy tests from 1 to 22 Joules. New features include an intuitive software interface with a 7-in. color touchscreen. Safety features include an emergency stop button and a two-hand pendulum release mechanism. New solid, one-piece hammer-arm design utilizes FEA (finite element analysis) methods to ensure proper center of percussion, thus minimizing vibrational losses.

A brand-new video extensometer that is said to be the fastest, most accurate, non-contacting strain-measurement device will be showcased by Instron (see February Keeping Up).

Among new weather-testing instruments and services, Eye Applied Optix will unveil its Eye SUV-W-161 UV-durability test chamber. It reportedly delivers UV energy 30 times greater than natural sunlight to generate acceleration factors more than 10 times greater than typical xenon chambers.

Atlas Material Testing Technology will showcase an upgraded full-spectrum xenon instrument, the Ci4000 Weather-Ometer, which features a new user interface along with enhancements such as an integrated FSM full-spectrum monitoring system,

WXView/WeatherView data acquisition software, S3T online specimen surface-temperature measurement system, and RD-3T specimen holders that can reduce rack-loading time by more than half.

Meanwhile, some interesting new and upgraded analytical instruments will also be on hand. For example, what is said to represent a completely new gel-permeation/size-exclusion chromatography platform is the Omnisec GPC/SEC from Malvern Instruments. This product is said to break ground in delivering high performance, ease of use, and productivity.

Linseis, Inc. will showcase three new thermal analysis instruments, including its high-temperature DSC PT1600 differential scanning calorimeter, which reportedly has the industry’s highest calorimetric sensitivity, short-time constants.

New color and appearance instruments will be featured by Paul N. Gardner Co., including a new gloss/texture measuring instrument for 3D surfaces (see January Keeping Up) and a haze and transmittance meter that simultaneously measures haze and clarity (see February Keeping Up).

Zeiss Industrial Metrology will feature the Metrotom 800 computer tomograph, which was developed for 3D measurements and structural inspection of complex parts. It enables both dimensional measurement of the geometry and inspection of the interior structure of parts.

WELDING & SEALING

Several new and upgraded welding and assembly machines will be prominent at the show. Among them is the new VW5000 Series of vibration welders from Dukane Corp. They are said to incorporate improved process control, more data storage, and easy programming, along with backward tooling compatibility. These welders feature Dukane’s patented proprietary digital frequency drive, which is said to deliver significantly more power, efficiency, reliability, and flexibility, along with a 15-in. color touchscreen.

Also new at the show is Dukane’s self-contained servo ultrasonic welder (see January Keeping Up) as well as an optional module for the company’s iQ Series ultrasonic generators designed to simplify work cells (see February Keeping Up).

Herrmann Ultrasonics announced that it will have live demonstrations of “functional integration” through interlinking of several production steps, noting that this approach simplifies production monitoring and quality assurance processes (see February Keeping Up).

Sonics & Materials is showing an ultrasonic stepper motor welder with touch-panel technology. One streamlined box houses both the controller and power supply (see February Keeping Up).

DECORATING, PRINTING, FINISHING

Apex Machine Co. will display its new C-9 syringe printer, said to be a low-cost solution for high-quality decoration. It features two-color, dry-offset, 360˚ printing at 150 parts/min.

Matthews Marking Systems will launch the VIAjet L-Series thermal inkjet printer, said to be a clean, fast, and cost-effective alternative to thermal transfer and adhesive labels. Leveraging the same cartridge technology found in desktop printers, the L-series provides high print resolution (600 x 600 dpi) reportedly at nearly twice the speed of previous thermal inkjet systems.

KBA-Kammann will feature its new, high-end model K15-CNC, a CNC-controlled universal screen printer that handles products of any shape—round, oval, square, flat, or handled. It is servo driven and can take six to 22 processing stations and up to 10 colors with UV curing or 12 colors with thermoplastic inks.

A patent-pending digital-print transfer printer for PVC pipe and profiles will be introduced by OMP. The DPT boasts one moving part and can cleanly print barcodes on PVC profiles, whereas standard PVC printers reportedly tend to leave unclear, wavy print on the substrate. In addition, it uses no harmful chemicals and has low ink consumption costs.

Other news includes a compact pad printer from Tampoprint International, which combines pad and laser printing in one automated unit; and a new atmospheric plasma device from Plasmatreat specifically designed to treat plastic composites such as SMC (see February Keeping Up).

Related Content

Metaspectral to Advance Vision Technology for Recycling

Company received further funding from British Columbia’s CleanBC Plastics Action Fund

Read MoreNOVA’s BOPE-HD Film Resin Gains in Globally Available Flexible Food Packaging Applications

Positioned as a recyclable packaging alternative to traditional BOPET films, BOPE-HD film is now available from companies such as Inteplast, JK Materials, Oben Group, and Polivouga.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreBenchtop Spectrophotometer Combines Several, Different Measurement Methods

BYK-Gardner’s new color2view said to open new horizons in color measurement.

Read MoreRead Next

Detect When Equipment Needs Maintenance—Before It’s Too Late

New technology to debut next month at NPE warns when preventive maintenance is needed, before equipment failure disrupts production.

Read MoreDetect When Equipment Needs Maintenance—Before It’s Too Late

New technology to debut next month at NPE warns when preventive maintenance is needed, before equipment failure disrupts production.

Read MoreDetect When Equipment Needs Maintenance—Before It’s Too Late

New technology to debut next month at NPE warns when preventive maintenance is needed, before equipment failure disrupts production.

Read More