Blow Molding at NPE: Pushing the Envelope in Speed, Flexibility, Energy Savings

NPE2012 News Wrap Up

New models of blow molding machines at the show were dominated by wheel machines and stretch-blow systems.

Numerically speaking, the new models of blow molding machines at the show were dominated by wheel machines and stretch-blow systems. The latter included both all-electric and electric/hydraulic hybrids. There was also news in shuttle machines and downstream auxiliaries.

WHEELS & SHUTTLES

Graham Engineering Corp. displayed its next-generation G Series high-speed wheel. The GS39 HS-18 incorporates some features of the company’s Mini wheel line in a much larger machine. The key mechanical innovation is independently built, self-standing clamps that form the core of the spool. In Graham’s previous wheel machines, the clamps were built off the spool. David Yenor, v.p. of global business development, says the new design allows the machine to be more easily reconfigured to run different products.

The 18-station machine at the show would typically run a neck-to-neck bottle pair, with two cavities per station, to produce 36 bottles/revolution. The machine, which is all-mechanical, with no hydraulics, can run at up to 13 rpm.

Known for its high-speed rotary machines for small containers, Wilmington Machinery introduced its first rotary blow molding machine for larger handleware, jerry cans, and tight-head drums from 2 to 5 gal. Jeff Newman, v.p. of sales and marketing, says these containers are typically made by shuttle or accumulator-head machines producing a maximum of two containers/cycle. Wilmington’s new continuous-extrusion rotary machine can produce 475 20-liter containers/hr—or 4 million/yr—about triple the production of a conventional single-station shuttle or accumulator-head machine, Newman claims.

The machine, which includes automation for part handling and trimming, produces containers with calibrated neck finish in four or six cavities. This is reportedly the first rotary designed with “moving cores,” wherein the bottom and top of the mold slide open prior to part ejection. The moving cores allow demolding containers with deep recesses in the handle and base areas. Wilmington is investigating potential use of the machine for making multi-layer gas tanks for automobiles and recreational vehicles.

The Rotary Wheel 8-15 Clamp system from R&B Plastics Machinery lets bottle makers fine-tune clamping speed to achieve desired productivity and also extend tool life. The clamp has proportional hydraulic controls and x-y blow-pin assemblies.

Bekum America displayed the latest addition to its line of shuttle machines, the BM-606D, operating in two-parison, four-cavity production of a 10-liter “F-style” bottle with a 63-mm Rieke neck finish. The bottle was designed with ribbing for lightweighting and was molded from sugarcane-based “bio-polyethylene” from Braskem of Brazil.

The main enhancement in the BM-606D is a larger, 20-metric-ton clamp with a maximum mold width of 650 mm, facilitating production of large handleware bottles of 10 or 20 liters.

STRETCH-BLOW MACHINES

In PET, NPE2012 saw the North American debut of the newest injection-stretch-blow machine from Automa S.p.A. of Italy. The hybrid model NSB 80 is aimed at PET bottles and jars from 20 ml to 8 liters in 2 to 14 cavities. The four-station machine has an 80-m.t. clamp and a hydraulic injection unit with a pump driven by an electric servomotor. It offers an adjustable stroke for blowing smaller preforms and reducing cycle time. Low power consumption of 20 Kw is aided by energy recovery of the servo motors during braking. The recovered energy is fed back to the servo motor.

Automa also announced the formation of a new business unit, Synthesi, which will use a modular approach to design and build customized blow molding machines based on customer selection of 12 fundamental machine units, such as shuttle stroke and clamp force, and other criteria such as materials to be molded. The combination of design parameters is reportedly capable of generating over 320 different machine models.

Aoki Technical Laboratory Inc. introduced its latest machine, the SBIII-150 N-12, targeted for high-speed, cleanroom production of small, narrow-neck containers for cosmetics and medical products. The machine has a clamp force of 12.3 m.t. and can run with 10 to 16 cavities for containers with neck sizes from 12 to 19 mm. At the show, the machine molded a 38-ml vial in 16 cavities with a 7.8-sec cycle time, which amounts to 7384 bottles/hr or 53 million/yr.

Having introduced its first and so far only all-electric machine, the ASB-15N/10E, in 2006, Nissei ASB Machine Co. announced it is now developing a hybrid line of machines as an alternative to all-electrics. Its first stretch-blow hybrid machine, the ASB-12M, is scheduled to arrive in the third quarter. The machine will be equipped with servo-driven hydraulic pumps and is aimed primarily at wide-mouth jars with necks up to 83 mm.

Italy’s Siapi s.r.l. extended its range of all-electric linear reheat stretch-blow machines with two new models, the EA4 and EA7, for 2- to 10-cavity production of demanding custom PET containers for cosmetics and household chemicals. The company also displayed recent projects in converting square, stackable 20L HDPE jugs from HDPE to PET and 5-gal water-cooler bottles from PC to PET.

Krones Inc. showcased the latest evolution of its stretch-blow technology, Contiform III, which the company claims will provide molders with reduced air and energy consumption in a line of rotary machines with 8 to 36 stations.

ANCILLARY UPGRADES

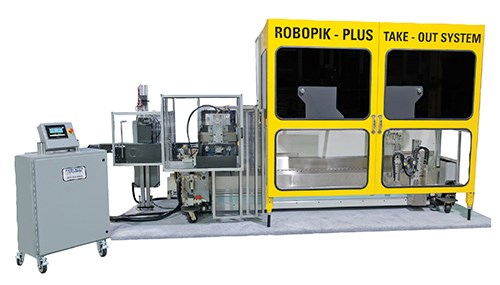

A number of companies touted innovations in blow molding auxiliary equipment and services. Proco Machinery, Inc. displayed what it says is the industry’s first takeout system with integrated deflasher and leak tester. The system incorporates Proco’s Robopik Plus model, which removes the container and transfers it directly to the deflasher or spin trimmer as needed. After deflashing, a telescoping vacuum conveyor extends to retrieve the container, hold it upright, and transfer it to the inline leak tester. The system is tuned to match the output of the machine. Siva Krish, sales manager, says the main benefit is space savings from eliminating separate deflashing and leak-testing stations.

Amsler Equipment Inc. introduced the latest version of its flying-head leak tester. The five-head unit offers a smaller footprint and higher output, and features a timing screw and pneumatic gating for bottles that are difficult to convey or prone to shingling.

Agr International, Inc. featured two new vision-based inspection systems. Pilot Vision mounts inside the blow molder to help processors evaluate PET preforms and bottles for random defects. OptiCheck is a multi-camera inspection system providing comprehensive defect detection for the entire bottle surface, including seal surface, sidewall, base, and label.

A new Scrap Control Release System from R&B provides precise handling of container neck flash throughout the entire deflashing process. The system, designed to work with deflash-trimmer equipment, features one set of neck-flash gripper tooling for many types of containers, which results in significant savings on container-specific tooling.

Kautex Maschinenbau has developed a new patent-pending rapid-prototyping technology that it claims can produce a blow molded sample within 48 hr from receipt of the 3D CAD drawing. The method eliminates the need to make a 3D solid model of the part, which can take up to 6 weeks, and instead CNC-machines cut inserts directly from CAD data. The inserts are then attached directly to the carrier plates and water lines inside the test machine.

Related Content

Coca-Cola Europacific Transitions to Tethered Caps and Lighter PET Bottle

Sidel is converting all Coca-Cola PET bottling lines in Europe to meet new EU packaging regulations by July 2024.

Read MoreAdding Remote Service Functions for PET Bottle Blowing

KHS has added features to its internet machine communications portal for PET stretch-blow molding.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreKrones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreRead Next

New PET Stretch-Blow Machines & Applications Debut at NPE

Italian stretch-blow molding machinery builder Siapi (siapi.it) had a lot to talk about at NPE2012 last month in Orlando, Fla.

Read MoreBlow Molding at NPE: Speed, Quality & Flexibility Take Center Stage

Wheel machines in particular will be on display.

Read MoreAll-Electric Blow Molding Is Reaching the Tipping Point

After years of talk, all-electric blow molding machines seem poised to make advances.

Read More

.png;maxWidth=300;quality=90)