Cut the 'Chatter' in Window Profile Extrusion

A new class of heat stabilizer and an unusual lubricant are said to allow high-speed extrusion of rigid PVC window profiles without such common problems as "chatter" lines, die plateout, and frictional heat build-up in the calibrator.

A new class of heat stabilizer and an unusual lubricant are said to allow high-speed extrusion of rigid PVC window profiles without such common problems as "chatter" lines, die plateout, and frictional heat build-up in the calibrator. Both the new stabilizer and the optimized lubricant formulation emerged from recent research at Crompton Corp.

Tooling technology developed in the last few years allows an increase in output rates for window main frames to 13-16 ft/min from the previous standard of 6-8 ft/min. With higher speeds have come some difficult technical issues, according to Perry Reed, manager of rigid PVC additives at Crompton. "Formulations for rigid PVC building products designed for standard low-output extrusion will generally not perform well at very high output rates," he says. Changing the stabilizer and lubricant package can allow operators to readily achieve 13-16 ft/min output rates, Reed asserts.

Eliminate chatter

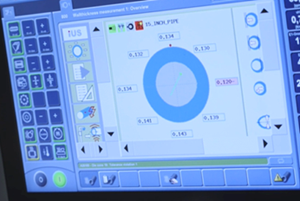

"Chatter" caused by binding and hesitation of the extrudate as it passes through the calibrator has been by far the most difficult problem to solve in high-output profile extrusion, Reed notes. Re peated binding and release of the extrudate in the calibrator leaves vertical lines along the profile surface. At lower extrusion rates, extruder conditions can generally be adjusted to solve the problem, but not so at high output rates. "Chatter problems can be so overwhelming that dramatically reducing output remains the only solution—an unacceptable one to a company that may have invested millions in high-output tooling," Reed says.

Enter Crompton's new class of organotin heat stabilizers, which have unusual lubricating properties. Traditional methyltin or butyl tin stabilizers are non-lubricating. The new Mark 2200 series of butyltin mercaptides reportedly possess both very high tin content and very high levels of external lubricity that cannot be matched with typical lubricants.

According to Reed, use of these stabilizers alters the profiles' surface tension and die-swell characteristics, allowing the extrudate to pass smoothly through the calibrators at high speed without any signs of chatter. Mark 2200 stabilizers also boast excellent early-color hold and long-term heat stability. Although Mark 2200 grades are priced higher, typical use levels are 0.8 to 1 phr versus 1.2 to 1.5 phr for standard stabilizers.

According to Reed, a compound containing Mark 2200 processes very well at 13 ft/min on a Davis-Standard 94-mm twin-screw extruder with an A&G high-output calibrator and dual-strand die.

Stop plateout & friction

Changes to any formulation ingredient can affect plateout or build-up on the outside of the die or inside the calibrator. Moreover, the faster an extruder runs, the quicker plateout will develop.

For high-speed extrusion, Reed says the total lubricant level should be kept at an absolute minimum. Also, the choice of lubricant chemistry should be examined critically. "Ester lubricants, although soluble in PVC, can migrate to the surface and cause a plate-out problem. Excessive use of external lubricants such as paraffin wax can also contribute to plateout. You want enough lubricants within your compound to prevent sticking and burning and to promote flow—no more, no less. Generally this level will be 2 to 2.25 phr," he states.

As line speed increases, so does frictional heat. So the choice of lubricant is also very important to minimize friction between polymer and metal. Standard formulations will generally result in a very hot and "soupy" melt at high output rates, which means the melt will be difficult to size properly. It will also tend to hang up in the calibrator, causing jams.

According to Reed, few processors recognize that certain higher-melting lubricants such as amides will help stiffen the melt. An example is Crompton's Marklube L123, which has both external and internal lubricating properties, whereas widely used fatty ester lubricants have lower melting points and act only as internal lubricants. Reed suggests that higher levels of external lubricants should partially replace internal lubricants such as fatty esters.

Metal-release additives such as calcium stearate are also essential to ensure that the polymer does not stick to the interior surfaces of the extruder. Higher levels of calcium stearate will provide both improved metal release and faster fusion, which is needed at higher output rates, Reed says. "Calcium stearate is a potent fusion promoter and a co-stabilizer," he notes.

Without revealing details, Crompton says a high-output lubricant system would increase the usual level of calcium stearate and replace the paraffin wax and ester lubricants with an amide like Marklube L123. (The oxidized PE wax remains unchanged.) In the high-output system, the overall level of lubricant is decreased from 2.45 to 2.20 phr. The lubricant system is rebalanced to provide faster fusion, better metal release, and improved heat stability. During production trials, Reed says, the standard system developed excessive frictional heat and could not be sized at high output rates, while the new system processed very well at 13 ft/min.

Related Content

High-Speed Cutters for Corrugated Tubing

Applications for new cutter line include medical, automotive, and other industrial.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreBelling Machine Forms 'Rieber' Socket in PVC-O Pipe

Italy’s SICA has developed an innovative Rieber belling process specific for PVC-O pipes. At the same operating pressure, these pipes require a wall thickness of about 35-40% less than those in conventional PVC pipe and allow the construction of water supply pipes up to 25 bar of operating pressure.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More