There is no doubt that a good understanding of the properties and processing behavior of a variety of resins and compounds will advance a custom processor’s business and bolster customers’ perception of the processor’s competence. Central to this achievement is having a well-equipped and well-staffed testing laboratory.

Such is the case with Teel Plastics Inc., Baraboo, Wis., a nearly 69-yr old, ISO 9001-certified processor that is best known for high-tech custom tubing and profile extrusion. Within the last five years, Teel also added injection molding capabilities, and was among Plastics Technology’s 2015 inaugural group of 25 World-Class Processors (now called Top Shops).

In 2010 the company launched a division called Teel Analytical Laboratories to support quality assurance and new-product development, and to troubleshoot manufacturing issues as they arise. With its certification to ISO 17025—marking the organization as a first-class laboratory in the area of material science and polymer analysis—Teel Analytical Laboratories offers confidential analysis services and consulting with a focus on polymer analysis, both for in-house use and for contractual business.

Plastics Technology asked lab manager Dan Clark to share some of the strong points of Teel Analytical Laboratories. To begin with, Teel has an extensive array of lab instruments to measure thermal, physical and mechanical properties of materials. For each of three key stages, typical tests include:

▪ Raw Material: Thermal analysis (DSC), physical analysis (density, melt-flow rate, particle size, durometer), chemical (FTIR).

▪ In Process: Chemical analysis (moisture, liquid chromatography), thermal analysis (TGA), physical (microscopy).

▪ Final Product: Mechanical analysis (tensile, flexural, impact, custom), chemical (liquid chromatography), physical (microscopy)

The laboratory staff has chemistry and/or biochemistry degrees and previous experience in materials testing. The lab also includes an in-house tool room so the staff can put the final product through actual end-use conditions. Teel’s engineers build the fixtures to allow for such testing with the appropriate instrumentation.

Says Clark, “Teel works with 75 to 100 resins per year—not necessarily all of which go into production. So we have this broad knowledge of materials ahead of time. We feel that this puts us in a position to guide and assist our customers in resin selection. We also stress to our customers the importance of material characterization.” Teel Plastics works with materials ranging from HDPE to PEEK and polyethersulfone (PES).

Clark describes Teel’s typical material characterization protocol as utilizing such tests as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), density, MFR, and Fourier-transform infrared (FTIR) analysis. Ideal frequency is five to 10 samples per lot, three-to-five lots of material. Data is collected, compiled and stored for future reference. Results show variation within a lot of material and the variation between lots of material.

“Teel works with 75 to 100 resins per year—not necessarily all of which go into production. This puts us in a position to guide and assist our customers with resin selection.”

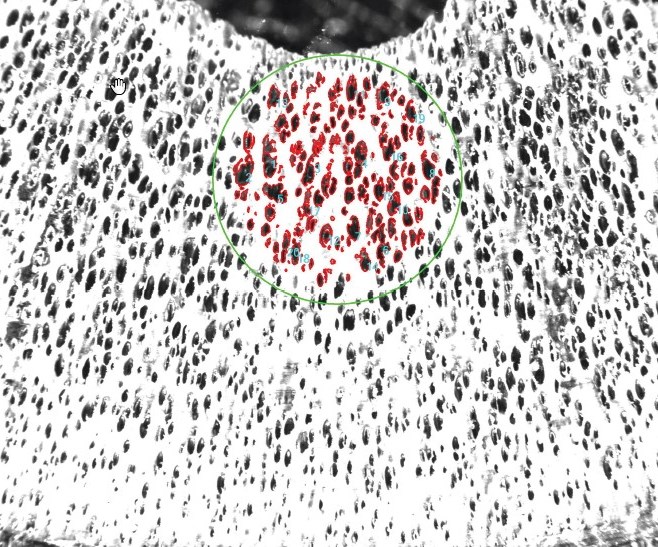

One of the latest acquisitions has been a microscope with software that measures foam cell size. “We have been using various chemical foaming agents in personal-care products we are producing. With the new instrument, we can determine foam cell formations and we can then tweak our extrusion process for optimal processing.” Prior to acquiring this instrument, Teel had to rely on mechanical performance to test the functionality of the end-use part. Materials Teel has foamed include PVC, HIPS, and acrylonitrile ethylene styrene (AES).

Troubleshooting Failing Parts

Asked to give examples where Teel’s materials’ know-how capabilities solved problems of a failing parts and processing problems, Clark offered the following:

▪ A customer found that its industrial core for film rolls was not performing adequately and wanted the core’s material—a PP compound, to be tested for abrasion resistance. Using its tool room, Teel’s lab staff performed the abrasion resistance test by building a fixture with grooves that simulated actual use. The material failed to perform up to par and Teel recommended a nylon 66 compound that proved well suited for this application.

▪ The ends of a PP extruded hollow core for water treatment for another customer were turning inward--called “bell-in.” Using DSC, the lab staff determined that the material in the inner diameter (ID) had higher crystallinity, which made that area more dense and “pulled-in” the outer diameter (OD) or whole wall. The solution was cooling the ID and the OD in such a way that crystallization was the same for both. “The ID had to be cooled faster due to the residual heat within the material, which continued to have an annealing effect,” explained Clark.

He says that while this processing example involved PP, this is an industrywide issue for polyolefin-based materials. “From the results of our testing, we are working on different cooling techniques to counteract the annealing that is occurring on the ID of the pipe from the residual pipe wall heat that is, in part, producing the bell-in event on the ends of the pipe.”

Related Content

How to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreIs Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

Read MoreCrosshead Die Features Single-Point Concentricity Adjustment

One adjustment bolt controls 360° of adjustment.

Read MoreRadar-Based Wall-Thickness Sensor

Measurement units include an array of these sensors positioned around the circumference of the pipe, which can be placed in multiple locations on an extrusion line.

Read MoreRead Next

Teel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing business controls its own destiny by controlling, well, everything.

Read MoreHow to Use Kinetic Modeling Analysis To Predict Profile Part Failure

Real-world project demonstrates how kinetic modeling can help estimate the shelf life of parts.

Read MoreIoT Strategy Cuts Human Error at Teel

Controlling up to 20 parameters from a single web interface has slashed setup time and increased output at a leading profile processor.

Read More