How to Use Commercial Purging Compounds in Extrusion

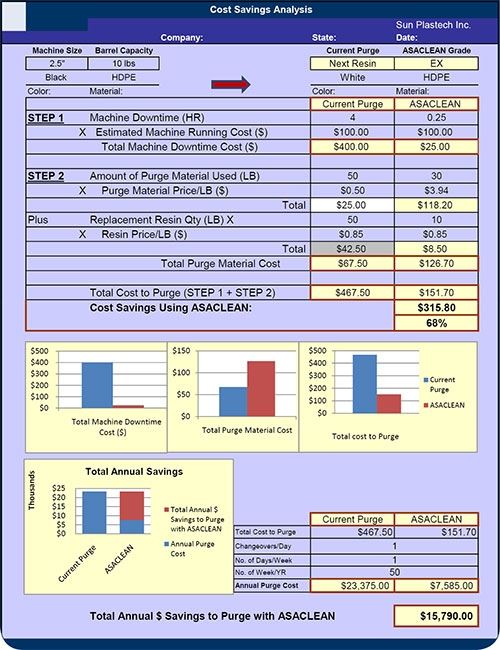

CPCs are considered most often for injection molding. However, they also can provide the same benefits to extrusion processors.

Use of commercial purging compounds (CPCs) has become an integral and even more vital part of thermoplastic processing. CPCs have proven to be invaluable tools for addressing market factors such as heavier reliance on just-in-time processing, increased pressure for cost savings in order to remain competitive, and use of more advanced resins, colorants, and additives. CPCs are considered most often for injection molding. However, they also can provide the same benefits to extrusion processors.

Historically, CPCs have been used less frequently in extrusion than injection molding because of equipment design and the fact that extrusion is a continuous process whereas injection molding is a cyclic process. Nonetheless, a CPC still offers many benefits to an extrusion processor:

•Color and material changes are faster using a CPC than with the traditional method of running hundreds or thousands of pounds of virgin material through the extruder to purge the previous material.

•Most CPCs are designed to remove stubborn carbon and color deposits while ordinary processing resins cannot.

•CPCs can prevent the need for screw-pulls; or, if they are required, can drastically reduce the time and effort required to overhaul the machine.

A CPC can be used for a wide array of extrusion processes: pipe, profile, tubing, sheet, film, compounding, and extrusion blow molding. CPCs are more commonly used in profile extrusion and compounding because changeovers are more frequent and the resins, colors, and additives are more varied. Most CPC suppliers offer a full product line of purging grades that address different resins as well as purging issues. Some suppliers even have formulations that are tailored specifically for extrusion, including more aggressive glass or mineral-filled grades.

‘DISCO PURGE’ & OTHER TECHNIQUES

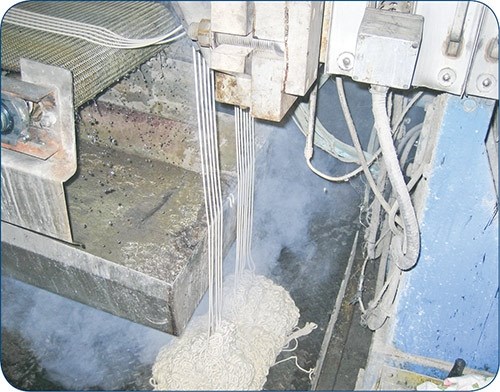

Purging the screw and barrel of an extruder is typically straightforward and easy, though it tends to become more difficult when more mixing/kneading elements are used. In most cases, one to three full barrels’ worth of CPC are sufficient to clean an extruder. CPC suppliers should be able to provide estimates on how much purge to use based on the screw diameter and how severe the purging application.

To maximize performance of the purging compound, it should be fed slowly in order to ensure that all the flights are full. Then increase the screw speed to the maximum safe rpm once the purge starts to come out of the machine. A mechanical purge benefits from the greater turbulence and agitation caused by higher screw rpm. During the purge, periodically stop the screw and allow the purge to settle into any “dead” areas. After a few minutes, start rotating the screw slowly, and then go back up to high screw speed. This stop-and-go purging, sometimes called a “disco purge,” provides a highly fluctuating environment of pressure and agitation that allows a purging compound to work its best. This is done until the purge is visibly free from any contamination.

Vented barrels are often difficult to clean because the vent is an area of low pressure and lower agitation. If the barrel has a vent, we recommend plugging the vent. If no plug is available, or if your company has a policy against doing so, we recommend that CPC be fed into the vent simultaneously with its feed into the main hopper.

Regardless of the type of extrusion process, the purging instructions for cleaning the screw and barrel are almost always the same for any particular CPC. But those instructions will likely vary when it comes to cleaning the die. The die is typically the most difficult area of the extrusion line to clean. While a mechanical-type CPC is often a great choice to clean the screw and barrel, a chemical-type purge, or even one that foams or expands, may prove useful in cleaning the dead areas that are common in dies.

While most CPCs are not expressly “die cleaners,” they often clean the die sufficiently or even completely. Raising the die temperatures by up to 50° F may help soften any deposits within the die—but don’t try this if running heat-sensitive resins.

In order to build up pressure, in many cases it helps to leave in place screen packs and breaker plates (if used). But ensure that the screen packs have openings sufficient to let the purging compound and the contamination it will remove pass through. Always check with the CPC supplier for screen-pack and die clearance requirements. It is also advisable to change the screen pack after purging is complete so that no purged contaminants break loose or bleed into the process.

A word of caution about melt/gear pumps: Some CPCs have no problem passing through these high-precision devices, but it is important to double-check with the CPC supplier about the particular purge compound before you run it. Also, a glass-filled purge should not be run through a melt pump.

In blow molding with accumulator heads, it is recommended to raise their temperatures by up to 50° F to help loosen any deposits. If the accumulator has a piston, an up-and-down “jogging” motion will provide agitation that can help remove contaminants.

Some CPC suppliers recommend special procedures to assist in reduction and prevention of contamination issues. For example, a periodic purging regimen should be established to prevent contamination build-up, which could lead to more complicated purging scenarios requiring greater time and effort. It is also recommended to do a “shutdown and sealing” with non-glass-filled grades during a temporary or extended shutdown. Sealing with a heat-stable material ensures that no further degradation occurs and also provides further cleaning. Processors using heat-sensitive resins such as PVC have found this recommendation particularly useful.

It is no longer debatable whether the use of a purging compound is crucial in thermoplastic processing, whether it be injection molding or extrusion. It’s clear that extrusion processors can benefit from the material and time savings that purging compound can offer. And it is these savings that can help give a processor that edge in today’s competitive plastics industry.

Related Content

Cooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)