Looking Back on 2021's Major Recycling and 3D Printing Stories

A review of the top recycling and 3D printing stories of 2021.

PureCycle’s proprietary process removes color, odor, and other contaminants from recycled feedstock, resulting in what the company calls “virgin-like” polypropylene suitable for any PP market. Photo Credit: PureCycle

As promised, 2021 saw big advances in the work toward a circular economy. This area continues to involve every aspect of the supply chain and it will grow. We also saw new technology emerging in the 3D printing space.

One of the biggest stories I covered was my On Site on PureCycle Technologies. The company holds a global license to commercialize the only patented solvent-based purification recycling technology, developed by Procter & Gamble (P&G) for restoring waste PP into what PureCycle calls “virgin-like” resin. The proprietary process removes color, odor and other contaminants from recycled feedstock, resulting in recycled resin suitable for any PP market.

Formed in 2015, PureCycle says it is the first company to focus solely on recycling and reintegrating PP into consumer products.

After I wrote the article, PureCycle has since announced KraussMaffei Extrusion will supply several extruders to PureCycle’s flagship plant in Ironton, Ohio. The company also announced the first product made from its recycled polypropylene technology has launched.

On the materials side, Eastman continues to see more demand for its Tritan Renew copolyester.

Earlier this year, Eastman announced that it is moving forward with its circular economy project in Kingsport, Tenn., which includes construction of the world's largest polyester material recycling facility and a Tritan polyester polymerization plant. The project is expected to begin producing at commercial quantities in 2023.

We saw more movement in the usage of ocean plastic as Sabic and Microsoft have collaborated to create Microsoft’s first consumer electronic product. The Microsoft Ocean Plastic Mouse features an exterior shell containing 20% recycled ocean plastic.

In the startup world, Belgian sustainable sunglass maker Yuma Labs is truly focused on a circular economy as the company’s specs are made from plastic reclaimed from the ocean—old bottles and nets, specifically.

Chemical recycling also generated a huge amount of interest. Independent consultant Sreeparna Das highlighted the various technology in the marketplace currently and on the horizon.

We also saw an interesting news item from Erema—its new large-size plant features a screw diameter of 280 mm, implemented for the first time in a Vacurema Basic 2628 T for producing rPET pellets. Erema has just shipped the plant to a customer in Brazil where up to 40,000 tonnes per year of rPET can now be produced.

3D Printing

In major trade show news, Mesago Messe Frankfurt announced that it has found the ideal partners in Gardner Business Media Inc (GBM) and AMT – The Association For Manufacturing Technology to launch the Formnext USA Chicago event which will be held April 8-10, 2025 at McCormick Place, in Chicago, Illinois, USA.

Arburg has combined all its additive manufacturing activities under one roof. The company has established a new subsidiary, Arburgadditive GmbH + Co KG, which is also based in Lossburg. Arburg Plastic Freeforming will switch entirely over to the new company in 2022.

Sabic and Local Motors completed a joint study on the feasibility of recycling scrap thermoplastic parts and shavings from the 3D printing process.

The study explored more sustainable alternatives to landfilling large, printed parts in anticipation of wider adoption of LFAM. It included analyzing the printability and mechanical properties of Sabic’s LNP THERMOCOMP AM reinforced compound, used by Local Motors, after being printed, reclaimed, ground and reprocessed into pellet form. The study determined that material from post-production parts and scrap can potentially be reused in LFAM or other processes, such as injection molding or extrusion, at amounts up to 100%.

My colleague Lilli Sherman just reported on that thanks to a 4D printing technology developed in the Fraunhofer Cluster of Excellence Programmable Materials CPM, printed polymers change shape once in a predefined way when heated. The extent of the change in shape of the printed objects is drastic: they can shrink by up to 63%. Fraunhofer researchers anticipate that in the future, 4D manufacturing technologies could be used to produce parts that exhibit a specific behavior only after they take their predefined shape, for example as fasteners in the assembly of components in the medical technology, mechanical engineering, automotive and aviation industries.

Essentium made the public demonstration of the Essentium High Speed Extrusion (HSE) 280i HT 3D printer at Rapid + TCT. This industrial-level 3D printing system features independent dual extruders (IDEX). A reported first-of-its-kind, this IDEX system is independent on both the Y and X axis, enabling manufacturers to 3D print multi-part builds at industrial speeds, even for parts with complex geometries.

Related Content

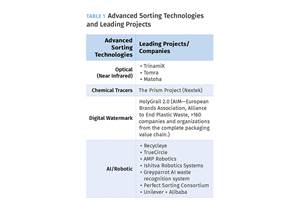

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreSD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

Read MoreRead Next

PureCycle to Supply Recycled PP to Berry

The material will be supplied to Berry in summer 2023 for manufacturing at one of Berry’s ISCC PLUS certified facilities.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More