KraussMaffei to Provide Extrusion Technologies for PureCycle

Two twin-screw extruders from KraussMaffei will melt the dry PP carpet scraps that are used as feedstock for the PureCycle process.

KraussMaffei Extrusion will supply several extruders to PureCycle’s flagship plant in Ironton, Ohio. The plant is scheduled to begin operating at scale in 2022.

“We are extremely pleased about this order and the trust PureCycle has placed in us,” says Carl Philip Pöpel, director of product management at KraussMaffei. “Acting as a full-line provider of various extrusion technologies, we are in a position to deliver an outstanding high-performance package solution that enables efficient and resource-conserving plastics recycling and offers substantial added value.”

PureCycle uses proprietary technology licensed from Procter & Gamble (P&G) to recycle waste PP into ultra-pure recycled-PP for applications spanning consumer goods, automotive, building and construction, and industrial uses.

The core component of the new PureCycle line is the extraction process. The technique cleans melted PP composite material from dye residues, foreign plastics and odors, providing for a pure PP melt and a recycled, re-usable co-product. The circulating solvent is then purified and returned to the process.

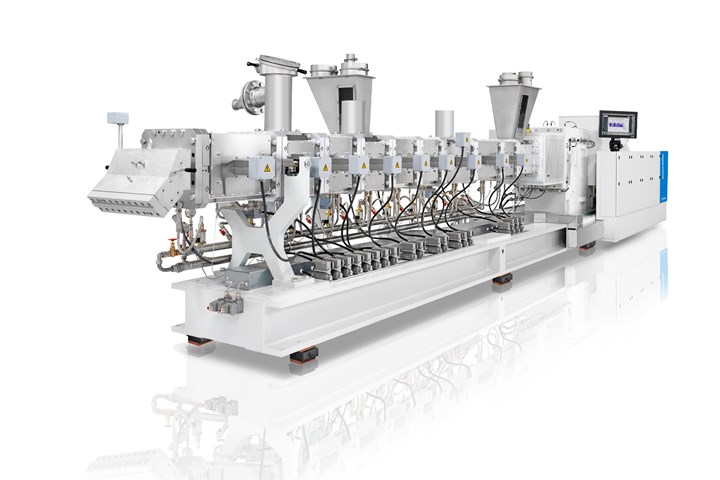

Two twin-screw extruders from KraussMaffei serve for melting the dry PP carpet scraps that are used as feedstock for the PureCycle process. These extruders are characterized by their ideal ratio between free volume and high specific torque, which makes them the first choice for processing the large-volume carpet scraps. Thanks to the high torque density of up to 16 Nm/cm³, they plasticize the starting material even at moderate temperatures and low speed and ensure optimum material homogenization and minimum energy consumption.

After passing PureCycle’s first processing stage, the cleaned melt is fed into the degassing extruder specifically designed to effectively remove any high-molecular residual monomers. Volatile matter like solvent residues and other impurities, such as adhering odorous substances and low-molecular compounds, are gently separated from the melt. The result is pure PP pellets that can easily be used to manufacture a wide variety of products by injection molding or extrusion coating processes.

“The collaboration and support we received from KraussMaffei has been exceptional. Collectively, we achieved real technical innovations and developed an exceptional solution for our process. We look forward to continuing this relationship as we scale our Ultra-Pure Polypropylene Technology globally,” said Scott Brown, vice president of program management at PureCycle.

“We are exceedingly proud that – based on the tests carried out in our R&D center and the jointly developed modular concept – PureCycle has opted for KraussMaffei's extrusion technology and that we can now make a decisive contribution to the world's most modern PP recycling plant,” Carl Philip Pöpel said.

ZE BluePower twin-screw extruder for processing PP carpet scraps.

Related Content

-

The Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

-

April 2025: Mixed Bag for Prices of Volume Resins

The end of the first quarter marked higher prices for polyolefins and relatively flat pricing for nearly all other resins.

-

Polyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.