New Technology Combines 3D Printing with Injection Molding

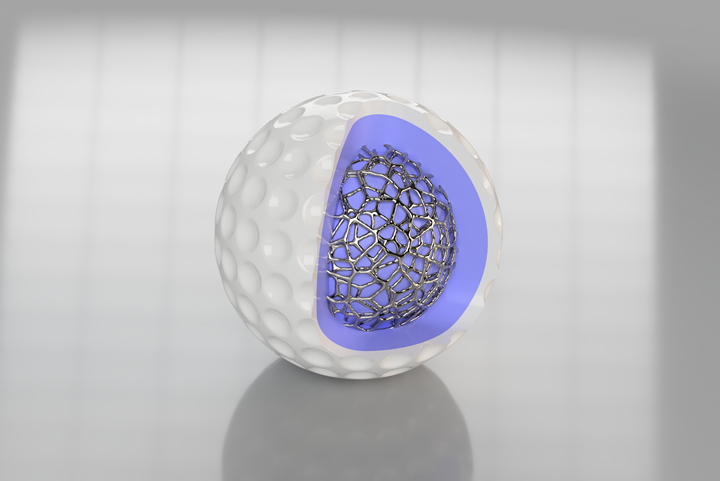

This new concept 3D prints a metallic endoskeleton and then injection molds a special polymer around that skeleton.

Cobalt Extreme is working on technology that builds a metallic endoskeleton via 3D printing, and then injection molds a special polymer around that skeleton.

A company in Brisbane, Australia, has developed a manufacturing technology that combines 3D printing with injection molding. Cobalt Extreme works on producing technology for engineering and manufacturing of innovative artificial lift equipment for oil production.

The company’s performance materials laboratory has developed a material concept called Synthetic Metal (worldwide patents pending), which was originally developed for extreme environments in deep oil wells. This technology has potential to open up applications in new markets.

David Nommensen, director of Cobalt Extreme, says the biggest advantage of Synthetic Metal is its processability, by injection molding a unique polymer in and around a metal endoskeleton. “The injection molded polymer in and around the metal endoskeleton is not conductive and becomes an insulator, in addition to other benefits of the injection molded material, such as abrasion resistance, resilient deformability, cost, impact resistance, corrosion and chemical resistance, color, service temperature and low weight,” he says.

The company’s Synthetic Metal and Arpmax polymer technology combines the electronic characteristics of metal with the engineering properties of polymers. “A metal endoskeleton adds mechanical strength to a polymer (think reinforced concrete),” Nommensen says. “Imagine a human body without a skeleton.”

Applications

An example of an application for Synthetic Metal is electrolytic-protection corrosion control in oil wells. Nommensen explains that a sucker rod is a magnet for corrosion in the presence of water and chemicals like H2S, CO2, and O2. Cobalt Extreme created the Cobalt Synthetic Metal sucker-rod guide anodes to combat this.

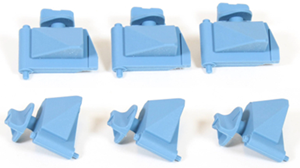

Synthetic Metal concept is used to create sucker rods for the oil and gas industry.

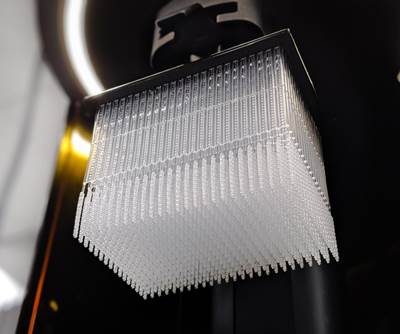

The process is unique in combining plastic molding with 3D metal printing of the anode matrix to align with the very specific shape of the company’s existing sucker-rod guide designs. Nommensen says the design of the 3D metal printed anode matrix is in two halves that are snapped onto the rod prior to injection molding of the spiral rod guide. The hydrodynamic design takes into account anode thickness, strength, openness and consistent surface contact to ensure that the function of the original centralizer is not compromised and that sufficient surface contact is made to create the required electrical circuit to be effective in preventing corrosion.

Nommensen says the current alternatives for managing corrosion in oil and gas wells are either epoxy coatings, thermal spray metal coatings or injection of a liquid chemical corrosion inhibitor. Installation of Synthetic Metal anodes reverses the galvanic action and the corrosion then reacts on the anode rather than the tubing and the rods.

The Synthetic Metal anode is contained within an injection molded Arpmax polymer to both ensure controlled cathodic protection of the metal sucker rod and the sucker rod are effectively centralized via the polymer guide/centralizer with the well production tubing.

“The Synthetic Metal innovation is to utilize advanced additive manufacturing technologies to combine proven anode metallurgy with Arpmax polymer technology to create a polymer with the electrical/ thermal/conductivity and the structural strength of metal,” he said.

Currently, Cobalt Extreme works with ProX DMP 320 direct-metal printing (laser sintering) technology from 3D Systems and injection molding equipment, sourcing unique metal alloys and organic polymer materials suited to individual product characteristics.

Other potential applications of Synthetic Metal in conjunction with the Arpmax range of polymers include electronics, marine, aerospace, sports, medical and military. “Synthetic Metal technology also has significant non-oil-field applications looking for a polymer with the electrical, thermal conductivity and structural strength of metal,” Nommensen states. “Synthetic Metal offers new and unique material characteristics, which have yet to be fully explored.”

Related Content

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreRead Next

Key Additive Manufacturing Trends to Watch in 2021

EOS, HP, Carbon and Essentium give a preview of what to expect from additive manufacturing in 2021.

Read More20 Good Things to Come Out of 2020—Part 5

Additive manufacturing has emerged as the supply chain hero in many ways during the COVID-19 pandemic. While the recycling industry continues its push for a Circular Economy.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)