NPE Newsfinder: Compounding and Mixing

For the second straight NPE show, the focus in compounding is on twin-screw machines that deliver more speed and torque—thus more output—than ever before. No fewer than six suppliers of twin-screw compounders are showing such machines. There’s something to see in in-line systems as well. And there’s plenty of news in PVC mixers and pelletizing equipment, too.

For the second straight NPE show, the focus in compounding is on twin-screw machines that deliver more speed and torque—thus more output—than ever before. No fewer than six suppliers of twin-screw compounders are showing such machines. There’s something to see in in-line systems as well. And there’s plenty of news in PVC mixers and pelletizing equipment, too.

Twin-screws show muscle

Higher speed and torque have been the battle cry of twin-screw machine builders since the K’95 show in Germany, when Krupp Werner & Pfleiderer introduced its first Mega Compounder, and Berstorff unveiled its Ultra Torque machine. At NPE 2000, no fewer than six machine builders will display high-speed/high-torque machines. While all this power generally comes at a 10-20% or higher price premium, the cost is at least partly offset by the fact that a new-generation machine reportedly outperforms a larger-sized machine from a previous generation.

At NPE, suppliers showing high-powered machines for the first time include American Leistritz Extruder Corp., Somerville, N.J., which is unveiling the HP Series of twins; B&P Process Equipment and Systems, Saginaw, Mich., which is displaying its just-introduced CT Series in sizes from 25 to 133-mm; and Kobelco Stewart Bolling, Inc., Hudson, Ohio, which is introducing the HyperKTX line.

Meanwhile, KW&P, Ramsey, N.J., is extending its line with the new ZSK 58-mm Mega Compounder for wood-flour processing (a developing trend in its own right). Berstorff Corp., Florence, Ky., is showing the ZE Ultra Torque machine line and the ZE Ultra Glide series of high-output laboratory and small-lot production machines. And NFM/Welding Engineers, Massillon, Ohio, is showcasing a 93-mm high-torque, high-speed twin-screw in the TEM Series (licensed from Toshiba).

In other extruder developments, Century Extruders, Inc., Traverse City, Mich. is showing the 3+ Extruder for the first time in North America. Introduced at K’98, the machine features a design in which a “ring” of up to 12 screws corotates around a static core.

Entek Extruders, Lebanon, Ore., will be showing three models of its corotating twin-screw extruders—36, 53, and 103 mm—along with a new quick-release die-head assembly.

HPM Corp., Mt. Gilead, Ohio, is introducing a 50-mm, twin-screw compounder that it has just started building through a licensing arrangement with APV Baker Perkins of the U.K.

Farrel Corp., Ansonia, Conn., will debut the Ultima Compounder, a two-stage machine that reportedly offers the highest dispersive-mixing capability available. The machine is a combination two-stage continuous mixer and a single-screw extruder on a unitized support frame. Extruder Technologies, Inc., is introducing the ET-20-CE twin-screw extruder that features a quick-change drive unit.

Berstorff is also going the low-torque route with a new machine designed chiefly for shear-sensitive applications. And Buss (America), Bloomingdale, Ill., will extend the operating range and flexibility of its kneader line with the introduction of 3:1 L/D barrel modules that enable its MKS-series kneaders to be custom designed for a range of applications.

A kneader series will be introduced by B&P Process Equipment. Like the Buss Kneader, B&P’s new CK and CKS machines have a single reciprocating screw that interacts with stationary pins on the barrel wall. Sizes from 30 to 220 mm provide outputs of 11 to 22,000 lb/hr of engineering thermoplastics, shear-sensitive materials, powder coatings, toners, and thermosets. The CK Series is said to offer 25-50% higher free volume than competing kneaders, plus screw speeds to 500 rpm. The CKS Series offers up to 1000 rpm and the same free-volume increase for maximum throughput capacity.

Systems that marry compounding with extruded-part production will also be prominent at the show. Leistritz will operate a twin-screw compounding and extrusion line making 40-in.-wide TPO sheet. Davis-Standard Corp., Pawcatuck, Conn., will also demonstrate in-line sheet extrusion from a D-Tex 96.5-mm twin-screw compounder.

Plenty of PVC mixers

There’s no shortage of news for PVC compounders at NPE. Colortronic Inc., Runnemede, N.J., is introducing the Nova Blend System, which combines technology from Colortronic and Waeschle of Germany to do away with conventional high-intensity batch mixer/cooler systems. Instead, a compact turbine mixer dryblends continuously. The result is savings in time, energy, space, and capital cost.

Caccia Engineering Spa of Samarate, Italy, is introducing new series of PVC turbomixers that reportedly permit throughput increases of 20%. Merlin Process Equipment, Houston (formerly known as Henschel), is introducing the Extex Planetary extruder for PVC calendering, as well as redesigned large vertical mixers and high-intensity mixers. Coronado Engineering, Inc., Kansas City, Mo., will show a redesigned version of the self-contained PVC compounding/blending systems it displayed at NPE ’97.

In other batch-mixing developments, Charles Ross and Son Co., Hauppauge, N.Y., is introducing the HV Blade for its line of planetary mixers. It enables mixing ultra-high-viscosity formulations that previously required high-horsepower, double-arm mixers. Draiswerke, Inc., Mahwah, N.J., is bringing out a new-generation Drais Gelimat Compounder, an ultra-high-speed fluxing mixer.

Pelletizing progress

Moving downstream, Beringer of Marblehead, Mass., is introducing the In-Line Water Ring Pelletizer, featuring a straight-through flow path and rates up to 5000 lb/hr. Color and material changeovers are reportedly quicker because there is no 90° bend in the flow path that is typical of crosshead designs.

At the booth of Black Clawson Converting Machinery, Fulton, N.Y., look for an improved version of its automatic pelletizer knife-adjustment system. Upgrades include faster and more powerful computer hardware and software.

Conair in Pittsburgh will unwrap the Model 208 strand pelletizer with a new slide-front design that allows tool-less maintenance and cleaning. It runs up to 2000 lb/hr.

Cumberland Engineering, S. Attleboro, Mass., has enhanced enhancements the Accrapak Model 900/8 strand pelletizer. It has an overhung rotor for easy cleaning and gear-driven feed rolls. Pellet length can be adjusted by a simple gear change.

New from Gala Industries, Eagle Rock, Va., is the MB500 Masterbatch Pelletizing System aimed at small-batch or full-production runs. A new tempered-water system allows quick and thorough cleaning between jobs.

Reiter Corp. is introducing the Primo 60E pelletizer, designed for simplicity and cost-effectiveness, as well as the Droppo mini pelletizer for lab and small-batch applications of low-viscosity polymers.

Scheer Bay Co., Bay City, Mich., will show three new products: ST-100 and SGS 300A strand pelletizers and WAA dewatering unit.

Carter Day International, Inc., Winnipeg, Manitoba, is showing for the first time its all-in-one Agglomerate/Dewatering unit for pelletizers, which reportedly eliminates the need for an agglomerate gate. Rotex, Inc., Cincinnati, is showing its new 100 Series Megatex Sensor for removing off-spec pellets. It has independently fed, multi-level screens in a deck arrangement.

New lab tools

For R&D work, Daca Instruments, Goleta, Calif., is showing a new version of its MicroCompounder that can be run from a standard PC. Haake, Paramus, N.J., is introducing its own Micro Compounder, a conical twin-screw machine shrunk down to a size that permits compounding and rheological measurement of batches as small as 8 g of material. Randcastle Extrusion Systems, Inc., Cedar Grove, N.J., has new single-screw compounding extruders with 50:1 or greater L/D and high-speed transmissions.

Buss believes it has extended the operating range and flexibility of its kneader line with new barrel modules of 3:1 L/D.

Related Content

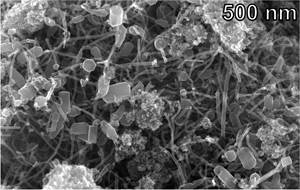

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More